Good morning

As this is my first post, at the beginning, hello to all forum members.

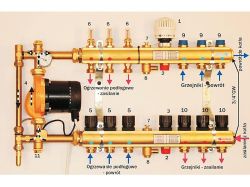

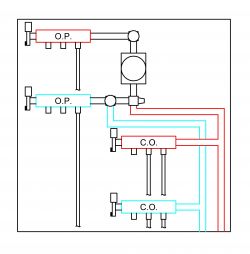

I was renovating the kitchen and I decided to use a floor heating for heating. One loop came out, about 90 m. I plan to connect it in the distribution cabinet, but I have two independent outlets for 2 heaters in this cabinet, which are located one floor above the above-mentioned. kitchen.

And here the question arises, how to connect it? The power supply goes directly from the furnace for eco-pea coal through a PEX 20 pipe.

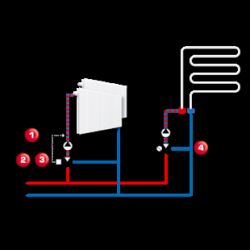

I was thinking about using a 2in1 splitter, eg TECE with a mixing pump, or is it an excess of form over content and unnecessary costs?

The second solution is a classic manifold without a pump with an RTL valve on the return from the floor heating, but here I am afraid whether the circulating pump next to the stove will be able to push 90 m of the floor heating, and whether the floor heating will not "take" heat from the two radiators that will be connected to common distributor.

I am asking for your opinion / advice on this matter.

PS People who use 2in1 manifolds, please give a short answer whether this solution works.

kisses

As this is my first post, at the beginning, hello to all forum members.

I was renovating the kitchen and I decided to use a floor heating for heating. One loop came out, about 90 m. I plan to connect it in the distribution cabinet, but I have two independent outlets for 2 heaters in this cabinet, which are located one floor above the above-mentioned. kitchen.

And here the question arises, how to connect it? The power supply goes directly from the furnace for eco-pea coal through a PEX 20 pipe.

I was thinking about using a 2in1 splitter, eg TECE with a mixing pump, or is it an excess of form over content and unnecessary costs?

The second solution is a classic manifold without a pump with an RTL valve on the return from the floor heating, but here I am afraid whether the circulating pump next to the stove will be able to push 90 m of the floor heating, and whether the floor heating will not "take" heat from the two radiators that will be connected to common distributor.

I am asking for your opinion / advice on this matter.

PS People who use 2in1 manifolds, please give a short answer whether this solution works.

kisses