FAQ

TL;DR: Budget circular saws often lose blade drive due to worn rotor–gear interfaces; one user saw 4 out of 4 fail this way, and the small gear "works out too quickly." Diagnose spindle/gear wear rather than just tightening the nut. [Elektroda, wojtek1234321, post #17014000]

Why it matters: This FAQ helps DIYers quickly pinpoint no-rotation or stalling causes and decide fix vs. replace on low-cost saws.

Quick Facts

- Typical failure path: small rotor pinion and mating gear wear, leading to blade stalling under load. [Elektroda, wojtek1234321, post #17014000]

- Repair economics (example): rotor ~60 PLN, gear ~15 PLN, new saw ~120 PLN; replacement often wins. [Elektroda, wiesiekmisiek, post #17013002]

- Common couplings: shuttle/keyed joints, riveted hubs, multi-splines; inspect these on tear-down. [Elektroda, Anonymous, post #17013965]

- Operating note: 600 W class saws need a sharp blade and full RPM before cutting to avoid bogging. [Elektroda, wiesiekmisiek, post #17014138]

- Edge case: very thin blades may not clamp securely; check for gaps at the flanges. [Elektroda, henrykS, post #16968187]

Why does my circular saw motor spin but the blade won’t rotate?

A slipping drive between the motor and blade hub is likely. If the spindle bolt or pin can be held still while the motor runs, the internal drive has lost engagement. That points to a worn or loose spindle-to-hub interface rather than the outer flange nut. [Elektroda, siejson, post #16968213]

How do I quickly diagnose a no-rotation or stalling blade?

- Unplug and remove the blade.

- Open the gear case and inspect the spindle–gear joint for looseness, missing key, or damaged rivets.

- Check for shuttle/key wear or deformed rivets on the drive hub, then reassemble with known-good parts. [Elektroda, Anonymous, post #17013965]

Will tightening the blade nut fix a slipping blade?

No. If the internal coupling is damaged, tightening the flange does nothing. As one expert put it, "Tightening here will do nothing." Focus on the motor-to-spindle connection instead and inspect the gearbox. [Elektroda, ta_tar, post #16968178]

Can a thin saw blade slip in the clamping flanges?

Yes, thin blades can fail to grip if the clamping faces don’t contact properly. Check for a visible gap and use the correct flanges or a proper bushing to ensure full contact and torque transfer. [Elektroda, henrykS, post #16968187]

What usually fails inside budget saws that causes stalling?

The small gear on the rotor shaft and its mate often wear out, leading to lost drive under load. One user reported 4 of 4 similar saws lost drive this way, adding the pinion "works out too quickly." [Elektroda, wojtek1234321, post #17014000]

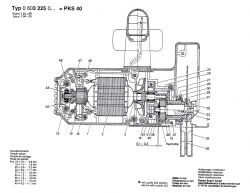

What is a shuttle/keyed joint on a saw spindle?

It’s a mechanical key that locks the gear or hub to the spindle to transmit torque. Some designs use a solid key, tubular rivets, or press-fit splines. Wear or shearing here allows the motor to spin while the blade stalls. [Elektroda, Anonymous, post #17013965]

Is repair or replacement more cost-effective for this failure?

For low-cost models, replacement often wins. Example figures shared: rotor ~60 PLN, gear ~15 PLN, while a new saw can be ~120 PLN. If both gears are worn, parts and time exceed the tool’s value. [Elektroda, wiesiekmisiek, post #17013002]

How should I cut to prevent blade stall on a 600 W class saw?

Use a sharp blade, let the motor reach maximum RPM, feed slowly, and avoid forcing the cut. Overloading slows the motor and accelerates gear wear. "We start cutting only when the saw reaches maximum revolutions." [Elektroda, wiesiekmisiek, post #17014138]

Do higher-end brands use the same type of gearing?

Yes, many sidewinder designs, including examples like the Makita HS7100, use a small rotor pinion driving a larger gear. Straight-tooth meshes are common and noisier but simple, and they still wear if overloaded. [Elektroda, wojtek1234321, post #17015382]

The spindle bolt or pin spins freely—what does that indicate?

If you can hold the spindle pin still while the motor runs, the internal drive has slipped. Expect a stripped coupling, damaged key, or worn gear teeth. Plan on teardown and parts replacement to restore torque transfer. [Elektroda, siejson, post #16968213]

Where can I get a shuttle key (org. 5131032545) for an RTS1800 saw?

Search by the OEM number and spindle assembly name, then match the shuttle/key profile during teardown. That part relates to the spindle–gear connection style discussed, so confirm the joint type before ordering. [Elektroda, Anonymous, post #17013965]

Are all circular saw blades the same thickness?

No. Blades come in different kerf and plate thicknesses, which affects clamping and load. Use flanges suited to your blade to ensure secure drive and accurate cuts, especially on lower-power saws. [Elektroda, miszapopiel1, post #21332149]

What edge failures should I watch for after repeated stalls?

Look for melted brush holders, overheated plastics, or deformed gear teeth after heavy bogging. One report noted a brush holder overheated and plastics finally melted after drive loss and overload incidents. [Elektroda, wojtek1234321, post #17014000]

How do I confirm if the gear teeth are gone without special tools?

Open the gear housing and rotate the motor by hand while holding the spindle. If rotation doesn’t transfer smoothly or jumps, the pinion or ring gear is worn. Replace the damaged gear pair as a set. [Elektroda, wiesiekmisiek, post #17013002]

Does over-tightening the flange risk damage?

Over-tightening won’t restore a failed internal drive and can warp the blade or mar flanges. Address the actual fault inside the gearbox instead of increasing clamp torque. "Tightening here will do nothing." [Elektroda, ta_tar, post #16968178]