Constructs a computer case. 100% plastic housing. From the inside, the elements are put together and glued with a canvas with resin. The priority in construction is the final weight of the whole. There is a lot of putties on the market, but I don't know which one to use exactly. The housing works during handling, lifting, etc., so ordinary putty is too hard. I saw that there are some kind of pseudo-flexible plastics (bumpers, etc.) but I don't know which one to buy so that it won't crack in the future. Gaps to be filled with max. 2mm, slot width max. 2mm and the material is plastic, similar to the printer housing, etc. It cannot be glued hot because you make powder and it breaks easily, hence the resin.

The housing will be painted (white mat + black mat). I know that I will cover the plastic with a plaster, but what about the putty?

Another question: mass!

Does the motherboard in mounting places (screwed in) have to have mass?

Do the contact points between the motherboard and the housing have to be massaged in any way, e.g. with the power supply?

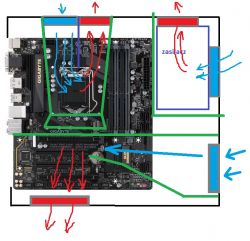

Another thing: cooling

I'm going to do something like this:

Made of canvas and resin as a tunnel cover for the CPU and heat sink.

Two fans are mounted on the wall of the housing (one draws in cold air from the outside and the other pushes out warm air).

Something like this will pass ??

The housing will be painted (white mat + black mat). I know that I will cover the plastic with a plaster, but what about the putty?

Another question: mass!

Does the motherboard in mounting places (screwed in) have to have mass?

Do the contact points between the motherboard and the housing have to be massaged in any way, e.g. with the power supply?

Another thing: cooling

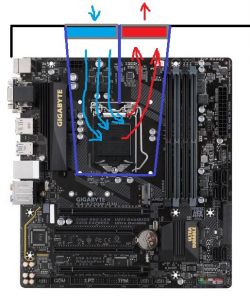

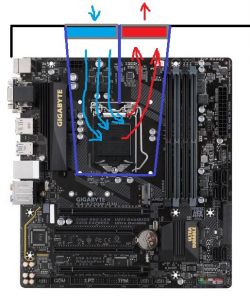

I'm going to do something like this:

Made of canvas and resin as a tunnel cover for the CPU and heat sink.

Two fans are mounted on the wall of the housing (one draws in cold air from the outside and the other pushes out warm air).

Something like this will pass ??