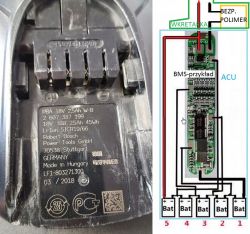

It is not necessary to drop the plate in the Boxer because one battery can be dropped and the BMS PCM protection detects that under load its voltage drops below the minimum 2.5V and STOP !! limit.

The charger charges up to 3x4.2V = 12.6V (3s-1p package) and in the dead battery the voltage increases quickly and is supposed to be OK. After direct connection, the screwdriver properly spins on two links.

The proposed BMS PCM module is ok, has the right current and is up to 3s but as far as I know Italian there is no balancer (it is not necessary but advisable). And how to connect the original charger that has a third temperature contact, and if it is not connected, it will not move.

Returning to Einhel 10x1,2V = 12V but max is 10x1,45V = 14,5V. BMS shown is 4S, i.e. as I wrote below 4S (14.8Vmax16.8V) so the voltage is too high and can damage the screwdriver, I advise you to give 3S-1p or 2p and BMS 3S (11.1V-max 12.6V). As for the original charger, the voltage will be OK, but you need to examine what current it gives when the battery is discharged ~ 8V (for 3S-1p max 2A for 3S-2p max 4A) and whether it has a temperature contact (it is necessary to leave the thermostat because it will not start)

A FEW RULES FOR CONSTRUCTION OF PACKAGES FOR Li-Ion, Li-Po batteries 3.6-3.7V (max 4.2V)

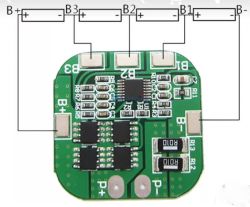

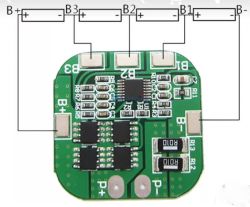

1. The cells in the package should be identical (preferably do not mix old and new ones) - the package is marked 1S (3.7V max 4.2V) or 2S (7.4Vmax 8.4V) or 3S (11.1Vmax 12.6V) or 4S (14.8Vmax16.8V or 5S (18.5Vmax21V) or 6S (22.2Vmax25.2V .................. etc.) The cells in the package can be connected in parallel and the quantity cells are marked with the digit + p, i.e. the package as in the photo is 3S-1p (3 individual cells in series.) When converting Ni-Cd packets into Li-ion batteries, the voltage should be properly selected and if there is space, connect 2p, 3p ... in parallel for high capacity.

2. Cells should have proper continuous discharge current, i.e. laptops are NOT SUITABLE for power tools because they have ~~ 4A current and 10-30A high current are needed

3. Aku Li-Ion are very sensitive to overcharging above ~ 4.25V / cell and excessive discharge below 2.5-3V, as well as exceeding the permissible charging and discharging currents. Therefore, it is necessary to use BMS PCM min15A security modules preferably with a balancer (the balancer loads each Xp level of the series individually) and chargers with current limitation (BMS does not control it), temperature control is also recommended. CELL OVERHEATING MAY CAUSE EXPLOSION OR FIRE.

PRACTICAL ADVICE:

1. BMS module after soldering with the packet can give 0V output because it has spark protection. To activate the package, connect it to the charger !!!!! Battery packets without a balancer disintegrate after a long time and certain links are systematically undercharged, which means that the charger does not want to charge them, and often it is enough that late cells in a row are loaded individually to make the package OK (for some time!).

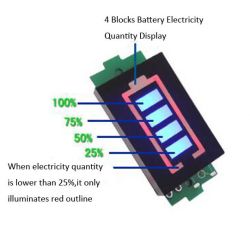

2. BMS modules, chargers with current-voltage limitation, voltmeters with 1-8S control can be bought cheaply in the network. And you have to make some effort to connect it all, build it up and run it.

3.You should buy ONLY high-current Sony, Panasonic, LG, Samsung, ... brand cells, if you can't afford new ones, they can be dismantled with a guarantee of almost nominal capacity in the range of 1.5-3Ah, for PLN 6-10 / pc.

4.When converting Ni-Cd to Li-Ion it is easier to buy a corpse screwdriver / Li-Ion wrench e.g. 18V Eubauer, Titan, Worx, Guild, JCP (compatible battery), break Ni-Cd cells into the trash and to blow out the original battery screw on the cut-off foot with the el. troupe. After purchasing complete Li-Ion batteries and a dedicated charger, you have slightly larger but lighter equipment of all kinds. If you already have other equipment on Li-Ion with similar voltage, it comes quite cheap. Having the adapter you can buy matching body tools both Li-Ion and much cheaper Ni-Cd. METHOD RECOMMENDED FOR DIY, NOT ELECTRONICS, because the work el. it is soldering two cables.

The example below is a vacuum cleaner - PLN 30 + PLN 18 (shipping), an Erbauer multifunction corpse with a charger and one battery is PLN 85 with shipping. So together 133 PLN !!! I skip that I still have a working engine, electronics and Erbauer bag, and that I have the opportunity to buy a whole range of Erbauer, Titan, JCB, Worx, Guild bodies ...