Hello all,

I plan to replace the old central heating installation from steel with copper and replace old radiators. Two different plumbers suggested two different pipe sizes and radiators.

The house has an area of approximately 110m2. the usable area is well insulated, I do not count the basement which is at ground level because there will be no radiators in it.

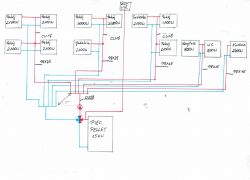

On the middle floor there is a 28 m2 living room, a 13 m2 kitchen, a bathroom (with a bathtub) and a corridor, and on the 1st floor there is 3 rooms, approximately 14 m2 each, a bathroom (with a shower and a corridor. There are 5 radiators on each floor).

Total: 13474W

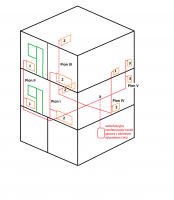

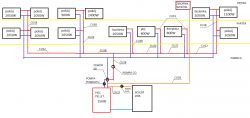

The stove is located in the basement and from it along the ceiling there are 5 "threads" to the risers and unfortunately it is not possible to change this arrangement. The furnace will be condensing, single-function by Saunier Duvall Thelia Condens 18kW and a container with a capacity of 150l by BIAWAR QUATRO.

RISER I, II, III, IV: pipes "run" under the ceiling to each of these risers, the distance from the furnace to the riser is about 6 meters, then each riser is about 3.5 meters, the distance from the riser to the radiator is about 80 cm

V VERTICAL (bathroom): distance from the stove to the riser: 2.5 meters, height of the riser about 3.5 meters:

1) One plumber's suggestion: Horizontal pipes from the stove to the risers, 28mm pipe, 22mm risers, 18mm radiator connections, return 22mm, and claims that 4 cast iron radiators that are on the top floor should not be replaced ...

2) A suggestion from the second plumber: horizontal pipes from the furnace to the risers 22mm pipe, 22mm risers, 15mm radiator connections, 22mm return

The proposal for the selection of radiators is similar for both men:

Radiators Nr.1 type C33: 3 pieces, each with a power of 1318W, a total of 3954W

Radiators Nr.2 type C32: 5 pcs, each with a power of 1750W, a total of 8750W

No.3 bathroom radiators: 2 pieces, each with a power of 435W, a total of 770W

Total: 13474W

I would like to ask for an evaluation / comment / advice regarding the choice of both men.

Thank you in advance

I plan to replace the old central heating installation from steel with copper and replace old radiators. Two different plumbers suggested two different pipe sizes and radiators.

The house has an area of approximately 110m2. the usable area is well insulated, I do not count the basement which is at ground level because there will be no radiators in it.

On the middle floor there is a 28 m2 living room, a 13 m2 kitchen, a bathroom (with a bathtub) and a corridor, and on the 1st floor there is 3 rooms, approximately 14 m2 each, a bathroom (with a shower and a corridor. There are 5 radiators on each floor).

Total: 13474W

The stove is located in the basement and from it along the ceiling there are 5 "threads" to the risers and unfortunately it is not possible to change this arrangement. The furnace will be condensing, single-function by Saunier Duvall Thelia Condens 18kW and a container with a capacity of 150l by BIAWAR QUATRO.

RISER I, II, III, IV: pipes "run" under the ceiling to each of these risers, the distance from the furnace to the riser is about 6 meters, then each riser is about 3.5 meters, the distance from the riser to the radiator is about 80 cm

V VERTICAL (bathroom): distance from the stove to the riser: 2.5 meters, height of the riser about 3.5 meters:

1) One plumber's suggestion: Horizontal pipes from the stove to the risers, 28mm pipe, 22mm risers, 18mm radiator connections, return 22mm, and claims that 4 cast iron radiators that are on the top floor should not be replaced ...

2) A suggestion from the second plumber: horizontal pipes from the furnace to the risers 22mm pipe, 22mm risers, 15mm radiator connections, 22mm return

The proposal for the selection of radiators is similar for both men:

Radiators Nr.1 type C33: 3 pieces, each with a power of 1318W, a total of 3954W

Radiators Nr.2 type C32: 5 pcs, each with a power of 1750W, a total of 8750W

No.3 bathroom radiators: 2 pieces, each with a power of 435W, a total of 770W

Total: 13474W

I would like to ask for an evaluation / comment / advice regarding the choice of both men.

Thank you in advance