Hello,

My vehicle is:

Skoda Octavia 2 from 2012. 2.0 tdi 103 KW, CFHC. Climatronic dual zone, DSG.

I browse forums, including the electrode. I have read a lot but I still haven't found a solution for my problem.

Namely, it began with a lack of air conditioning, i.e. inaction. Initial diagnostics has been done, namely:

Checking the refrigerant content in the air conditioning service - No loss.

Check. DELPHI diagnostic device - there were no faults

Checking the air conditioning pressure - 5.2 bar at rest (when switching on the air conditioning from the button - no reaction)

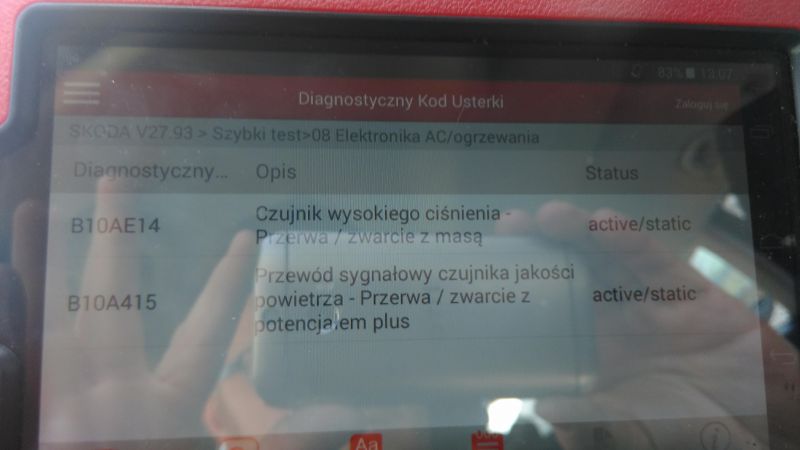

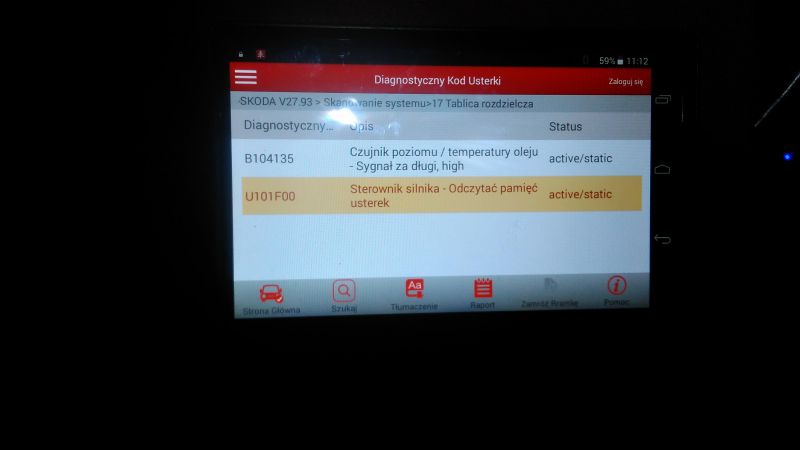

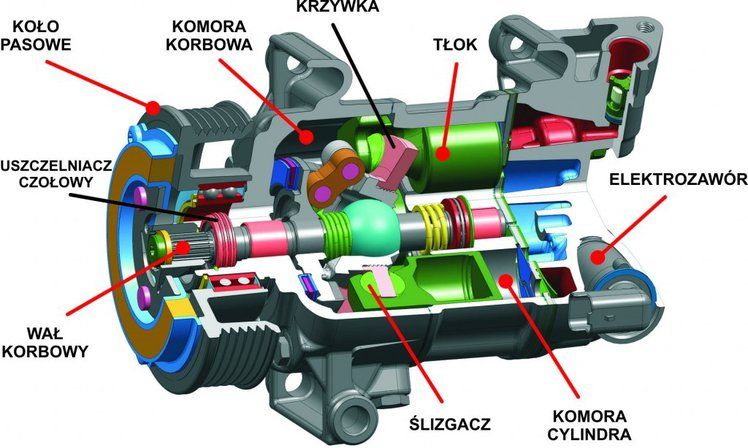

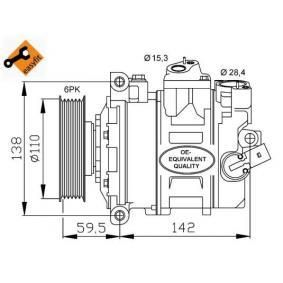

And because the compressor is DELPHI DH5 5K0 820 803 E 6CVC - one of the typical symptoms is the loosening of the M6 throttle screw (clutch), indeed the screw was unscrewed about 1-2 mm so I agreed in the workshop to replace the whole wheel with the clutch. And here the problems began. The gentlemen raised the mask, and did not listen to what I told them, just started checking the voltage tester on the compressor and sensors. After or took the car out of the hall and told me to go here next to another service and they would definitely help me because they are unable. So I wanted to go there, but I get in the car and my eyes appear flashing pictogram in yellow oiler, so I'm probably telling myself some inspection or mistake in reading the opening of the bonnet to refill oil. And here I was surprised, because after raising the mask with the ignition on and after 2 minutes. closing her problem persisted. I anticipate the question and say, there were no such faults before visiting that workshop. So go home and connect to another computer This time Laucher Tech with the X.431 PRO program. And after scanning such miracles:

- high pressure sensor fault break / short to ground - B10AE14

- air quality sensor fault, Air quality sensor signal cable - open / short to PLUS potential - B10A415

- Temperature / oil level sensor fault - signal too long, high - B104135

- Engine control unit - Fault memory reading - U101F00

They cannot be deleted !!

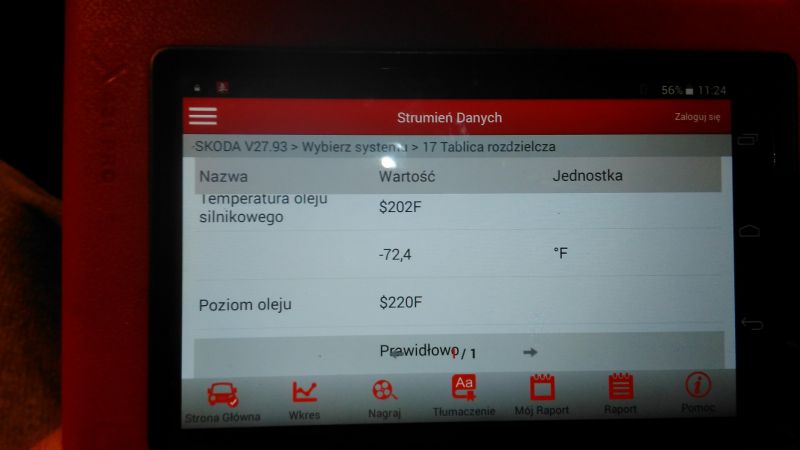

Well, I ordered an air conditioning pressure switch (switch) - 37 PLN, exchange, no change. (the old one did not show any resistance on the pins, the new one showed such resistance (I do not remember the value), I ordered a pulley with a vibration damper for the compressor 180 PLN, replacement and compressor turns, so glad I turn on the climate and here warm air from the vents. Well, I ordered a sensor air quality (original RECEIPT 1K0 907 659) waiting for delivery, and HELA was ordered - 95 PLN temperature / oil level sensor for the oil pan. The change and to my surprise did not help and only the description of the defect changed to the incorrect reading, and the next day again for too long signal. Voltages on pins from this sensor I did not measure, somehow I did not come up with this idea, but instead I came up with another idea and I checked the actual readings of this sensor and the temperature came out -72F, the oil level was correct. I poured fresh oil in a bottle and dipped the oil reader to the cable in the oil so that it replenished in the channel to Now I have doubts about these faults and I get the impression that the Professionals Professional have mixed up something with the electrician and I bet that they either ate something on the CAN or on the meter. As for the air conditioning, I am waiting for the delivery of the last sensor and it will turn out whether the air conditioning pressure sensor (switch) is associated with releasing voltage from the air quality sensor. That is, as quality over is damaged then part no pressure is applied because from what I read it should not matter and both systems are independent of each other (they have their own +). The signal has also been checked (voltage on the solenoid valve is there regardless of whether the engine is running or not 5 volt). After connecting the solenoid valve for a short time 12V pops, so I assume that it works unless the needle is not working and the high pressure cannot be opened.

Has anyone had such a problem and knows the solution to at least one of these problems without having to turn off the oil sensor in the meter (inspection is still at 7,000), or are there any other oil temp sensors, e.g. in a DSG gearbox that is associated with showing the temperature MFA (the temperature in MFA was shown at the time of entering the hall of a slick workshop, because I like to control the parameters)

Regards.

My vehicle is:

Skoda Octavia 2 from 2012. 2.0 tdi 103 KW, CFHC. Climatronic dual zone, DSG.

I browse forums, including the electrode. I have read a lot but I still haven't found a solution for my problem.

Namely, it began with a lack of air conditioning, i.e. inaction. Initial diagnostics has been done, namely:

Checking the refrigerant content in the air conditioning service - No loss.

Check. DELPHI diagnostic device - there were no faults

Checking the air conditioning pressure - 5.2 bar at rest (when switching on the air conditioning from the button - no reaction)

And because the compressor is DELPHI DH5 5K0 820 803 E 6CVC - one of the typical symptoms is the loosening of the M6 throttle screw (clutch), indeed the screw was unscrewed about 1-2 mm so I agreed in the workshop to replace the whole wheel with the clutch. And here the problems began. The gentlemen raised the mask, and did not listen to what I told them, just started checking the voltage tester on the compressor and sensors. After or took the car out of the hall and told me to go here next to another service and they would definitely help me because they are unable. So I wanted to go there, but I get in the car and my eyes appear flashing pictogram in yellow oiler, so I'm probably telling myself some inspection or mistake in reading the opening of the bonnet to refill oil. And here I was surprised, because after raising the mask with the ignition on and after 2 minutes. closing her problem persisted. I anticipate the question and say, there were no such faults before visiting that workshop. So go home and connect to another computer This time Laucher Tech with the X.431 PRO program. And after scanning such miracles:

- high pressure sensor fault break / short to ground - B10AE14

- air quality sensor fault, Air quality sensor signal cable - open / short to PLUS potential - B10A415

- Temperature / oil level sensor fault - signal too long, high - B104135

- Engine control unit - Fault memory reading - U101F00

They cannot be deleted !!

Well, I ordered an air conditioning pressure switch (switch) - 37 PLN, exchange, no change. (the old one did not show any resistance on the pins, the new one showed such resistance (I do not remember the value), I ordered a pulley with a vibration damper for the compressor 180 PLN, replacement and compressor turns, so glad I turn on the climate and here warm air from the vents. Well, I ordered a sensor air quality (original RECEIPT 1K0 907 659) waiting for delivery, and HELA was ordered - 95 PLN temperature / oil level sensor for the oil pan. The change and to my surprise did not help and only the description of the defect changed to the incorrect reading, and the next day again for too long signal. Voltages on pins from this sensor I did not measure, somehow I did not come up with this idea, but instead I came up with another idea and I checked the actual readings of this sensor and the temperature came out -72F, the oil level was correct. I poured fresh oil in a bottle and dipped the oil reader to the cable in the oil so that it replenished in the channel to Now I have doubts about these faults and I get the impression that the Professionals Professional have mixed up something with the electrician and I bet that they either ate something on the CAN or on the meter. As for the air conditioning, I am waiting for the delivery of the last sensor and it will turn out whether the air conditioning pressure sensor (switch) is associated with releasing voltage from the air quality sensor. That is, as quality over is damaged then part no pressure is applied because from what I read it should not matter and both systems are independent of each other (they have their own +). The signal has also been checked (voltage on the solenoid valve is there regardless of whether the engine is running or not 5 volt). After connecting the solenoid valve for a short time 12V pops, so I assume that it works unless the needle is not working and the high pressure cannot be opened.

Has anyone had such a problem and knows the solution to at least one of these problems without having to turn off the oil sensor in the meter (inspection is still at 7,000), or are there any other oil temp sensors, e.g. in a DSG gearbox that is associated with showing the temperature MFA (the temperature in MFA was shown at the time of entering the hall of a slick workshop, because I like to control the parameters)

Regards.