carrier wrote: gradek83 and that was it, it should be ok

I warn you against choosing a crimper by eye, especially if you write about professionalism in advance. You have to start with the type of connector, or at least its raster, and select a press tool for that.

It may not even be possible to use a crimping tool for another purpose, or it may result in poor tightening.

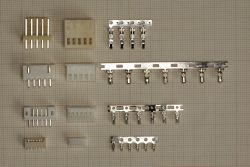

Take a look at this example:

There are quite popular connectors here, on the left ZH (1.5mm raster) on the right PH (2mm raster) where you can clearly see how different the dimensions of the plates are in the places of crimping. And for these two types of joints, different crimping tools are used, which clearly differ in the widths of these cuts.

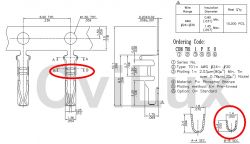

Here, too, in the videos that my colleague gradek83 gave, you can see a clear, visible difference in the size of the holes between the SN-03BM and SN-01BM crimping tools shown.

The former is probably for small connector plates with a 1.5mm pitch, as shown here, ZH, and the latter may be for those PHs with a 2mm raster, and even in poor data at sellers, this type is mentioned. But these are only my assumptions and it is difficult for me to judge anything. Especially that these crimping tools here, for various reasons, I would not call professional and the quality of the crimping is unknown. Only the price is attractive for amateur use, because typical correct crimping tools, e.g. from Molex or JST, are a completely different price category.

So check the raster of the connectors that you showed here at the beginning, because I have not noticed that you would specify it anywhere.