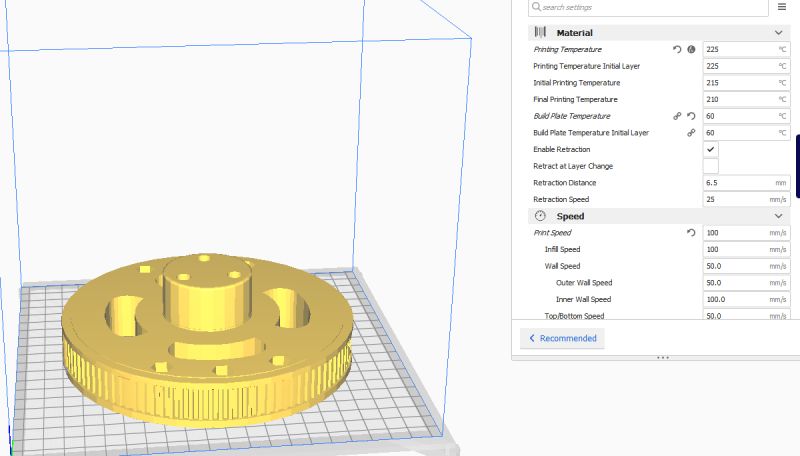

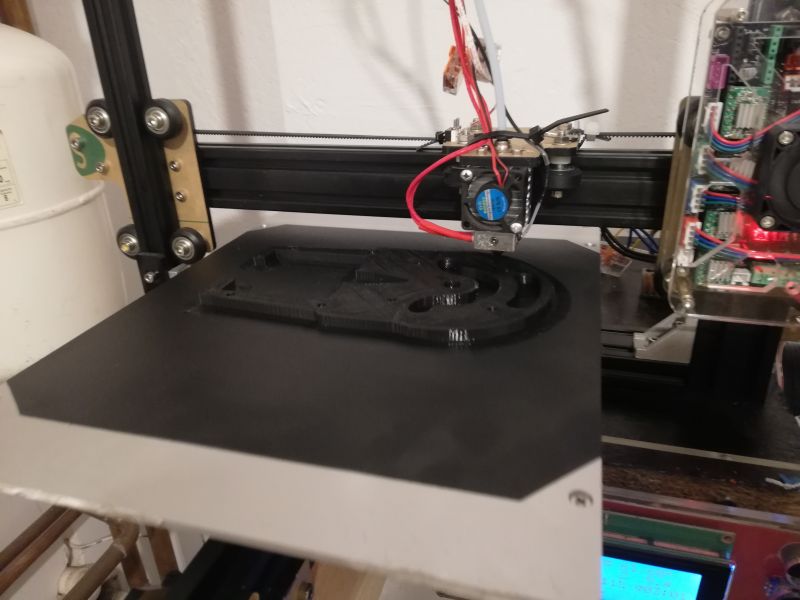

I am the owner of the Tevo tarantula printer as in the attached photo.

After a considerable explosion of this printer, the stuck Teflon "cover" of the table was damaged. I decided to pull off the leftovers completely and clean the hob. In the meantime, I ordered a new adhesion overlay. Until she didn't come, I tried tapes and to no avail, finally read about blue paper tapes. It's a bit better when you stick it on an aluminum plate, but the filament also deforms and comes off.

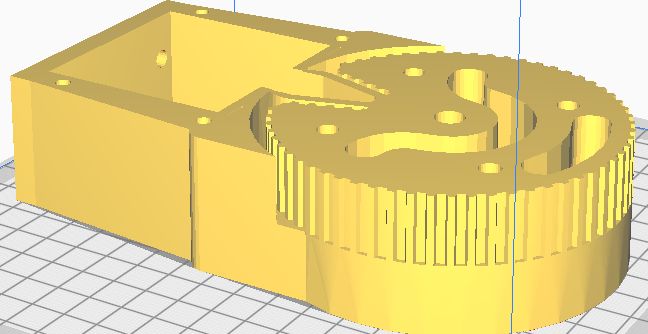

I want to print large items with full fill, and I keep stopping my 22 hour printing, already wasted a lot of filament.

I print on PLA.

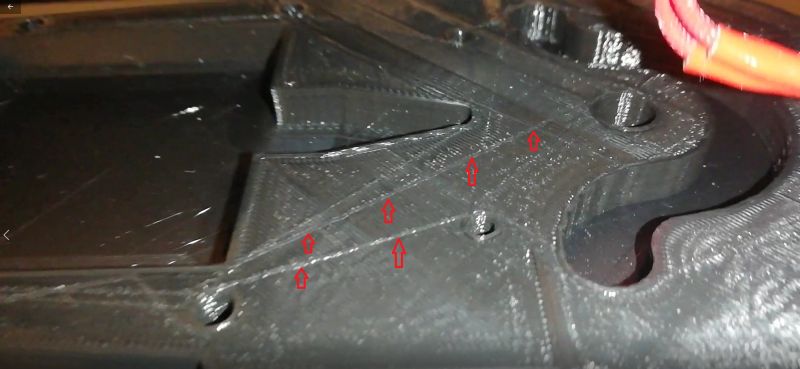

Yesterday a new original sticker came on the plate and today after work (17 hours of printing) I can see that the PLA sticks to the sticker but the sticker is detaching from the plate! The disc was thoroughly degreased before sticking, and then pressed carefully.

Do you have any advice for me on how to save this printer?

Previously, I had problems with jamming filament and the problem has been solved, maybe now it will work as well.