First of all - thanks for the answer !!!

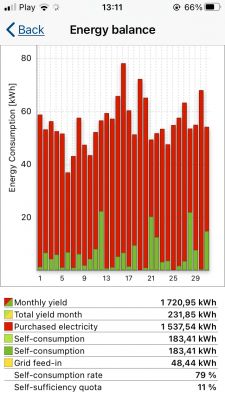

The annual electricity consumption is about 2700-2800 kWh. I have hot water heating from the sun (100% for half a year) + gas. My long-term goal is to give up LPG gas (no possibility from the network). But I have a contract and I have to deal with them for almost 3 years (high cancellation costs before that date). The heating current was supposed to be only a supplement for the time being.

Ultimately, it wants to add more panels to the roof and close everything with electricity. A buffer would be a nice solution, but I don't have space for it, and I won't put it in the living room

)) ... only the option of the tank outside would be considered, but the costs of the tank and its insulation would certainly be high, and having photovoltaics, it makes no difference to me if it heats with a stove in the 1st or 2nd zone. So I am left with an electric stove or a heat pump. The stove + all costs are PLN 3800, the pump would cost much more.... So I prefer to furnace + more photovoltaics.

In practice, the power of the stove is 5-7 kW. With a cold installation, eg in the morning, the contactor does not turn on for a long time and works perfectly. But as the installation and the floor (underfloor heating) absorb less heat, the contactor trips every few minutes. And this may be the reason for my failure - the number of starts and stops was quite large. The buffer would help here, but I have nowhere to fit it, unless it is 100-150l - but does it make sense?

Smooth power control would definitely help

))... I like your description, but I must admit that I don't understand much of it yet. I don't know much about electricity.... And if you could write me more precisely, I would be grateful.

If he's well versed, it's 3x230v. the boiler has 3 electrodes and each is connected to 1 phase conductor + N conductor, and to earth. Theoretically, 1, 2 or electrodes can be turned on, but you need to control it somehow. Ideally, it would be possible to smoothly control the power, if necessary, reduce the power to keep the output temperature constant, but I am not sure how to do it. At the same time, I would like to be able to control the DHW supply (to the tank through a coil with a working temperature of e.g. 80 degrees Celsius) and CO. But I do not know how to do it. I found the GH07EB driver on the website

http://www.geco.pl/prod.php?id=182&lang=pl, I thought to work with it. But maybe there will be the same problem with the contactor ...... I don't know anymore; (((

Ps. The warranty was there, but it was over.