Hello,

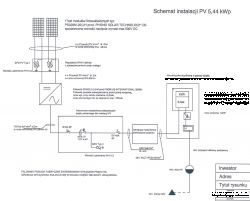

I have made a PV installation on a roof covered with steel tiles. The building has installations in the TN-S system and does not have a lightning protection system.

The inverter is grounded to the PE bus. As for the panels and structures themselves, the contractor claims that there is no need for additional installation on the roof.

Is the contractor right in this case? Are there any laws regulating this?

I have made a PV installation on a roof covered with steel tiles. The building has installations in the TN-S system and does not have a lightning protection system.

The inverter is grounded to the PE bus. As for the panels and structures themselves, the contractor claims that there is no need for additional installation on the roof.

Is the contractor right in this case? Are there any laws regulating this?