In fact, I thought about publishing this material here on the forum for quite a long time. My concerns relate to the safety of such a repair. However, while browsing the internet, a dozen or so pages presenting a similar activity and the number of sold DC power cords for laptops, I decided that maybe it is worth including it, but at the same time sensitize to the danger of such an "operation". In my opinion, too few people paid attention to it in the materials I read. The danger I am writing about is the correct, later assembly of the plastic housing. It is worth mentioning at once that no manufacturer of a device equipped with such a power supply allows any interference, repair, etc. of this element. In the event of any damage, only complete replacement. No item, component or wire appears in the "part list" of the service manual. Of course, one can argue whether this is the right way, or is it not better to just use dismountable power supplies? It's just that the manufacturer does not have any interest in this, and we are left with what we have.

The power supply presented here comes from the Lenovo laptop model, its exact designations are: ADP-90RH B. Damage is the periodic interruption of charging. We have a blue LED here that indicates the presence of voltage. So you can immediately suspect that the problem may be somewhere at the output of the power supply. Of course, to suspect, because the voltage signaling by means of a lit diode does not always mean 100% power efficiency.

An in-depth examination, which must always be done first, shows our problem. A interrupting cable, unfortunately in the worst, but at the same time the most common place - right next to the bend at the housing. Sometimes it can happen that a damaged wire will short-circuit the two wires inside. Therefore, it is not worth "bothering" such a "patient" for too long in the event of a defect.

Another common place is at the plug itself - and in this case the repair is much simpler because we can replace the plug itself without having to take the whole thing apart.

Unfortunately, we have to separate the casing, because it cannot be done in another way.

We proceed to "disassembly". As mentioned earlier, let's first check if the manufacturer hasn't hidden any screws under the stickers or feet. If not, which is the vast majority, what you are about to see awaits us. :)

Of course, we disconnect the power cord. It is worth noting that the high voltage inside the power supply will persist even for several seconds after disconnecting the 230V cable. Check how long the LED is still on.

One of the methods I know, for a reasonably "nice" and correct disassembly of such a housing, is to position the blade of a knife, preferably a decent one, in the gap between the halves and hitting the knife with a hammer. You do not need to use a lot of force, piece by piece, this way we can open the non-dismountable housing. It should be remembered that the entire operation should be carried out on a stable, hard surface that will not spring due to impacts. A good place is the top right above the table leg. If we overdo it, we will damage the casing or the components inside.

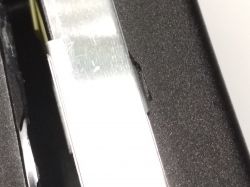

As you can see, this method managed to open with virtually no damage. The only slight flaw visible in the marked place. After folding the two halves, everything will fold without a trace. We don't have any dents or broken pieces of plastic here.

Another way of demolition is to saturate the connection points with a small amount of gasoline. A few drops. Wait a while, then the seal "lets go" and you can easily separate the two parts. With this method, however, you should follow safety rules, remember about the flammability of the product and ensure adequate ventilation. It's best to wait some time before doing anything until everything evaporates outside the room. I also read about cases where gasoline began to react also with the plastic casing.

The interior of our device is as follows.

Important note here, depending on the design solution on the metal outer parts, heat sinks, dangerous voltage may occur. It depends on the manufacturer, but it is worth not checking it on your own body.

At this point, we can buy a new DC cable and simply replace it in the world. However, I made my task difficult and used the old one. It should be mentioned right away that it is not worth doing this if you see that the cable is already quite "tired" along its entire length. Then we will add the work unnecessarily a second time. For me, however, 1/3 of the cable was fine, so I only left this one. And it was very long, and shortening it significantly did not stop, and maybe helped.

Some of the insulation may be left with bends inside, the factory holes in it will in most cases be too small to push the old wire back through. You can also try to drag it further, before you download it, but it will also be much more difficult.

Most often, you need to enlarge the hole in the "rubber" a bit so that the cable fits. However, it is worth making as small as possible, just to be able to pass the cable through. For convenience, you can cut a screen from a piece of the initial part, so that the beginning is thinner. Only after it is completely stretched, we cut off the unnecessary piece. That is why it is worth not to cut off "ready" at once, so as not to damage the mechanically proper part of the "cable". You also have to pay attention to how the strain relief was arranged in the housing - it is not always symmetrical.

We prepare the wires. I did as it was originally, the screen was twisted, additionally secured with a heat-shrinkable sleeve. In the original, the wires were crimped and soldered to the "connector". Here, after whitening the tips, I solder directly to the PCB. Of course, we remember about the appropriate polarity. Of course, we cut off the excess.

You still need to secure the cable against pulling out. There are different methods, some use cable ties, others just make a knot in the cable. I am not going to suggest anything, but you have to do it right, in the right place. In addition to the mechanical anti-pullout feature, it must also be secured against rotation, which is also undesirable. The cable is now not permanently connected to the strain relief, so such situations may arise. Glue is probably the best here. You just need to pay attention to its temperature properties (the power supply will heat up) and prevent it from flowing out of the outside.

Of course, all these activities are eliminated when we buy and replace only a dedicated cable for our equipment model.

We only have to assemble the housing correctly ...

Well, I left three dots to give you a chance to show off. What are your ways to correctly, reliably and, above all, safely connect these two plastic parts?

The conditions in which the equipment works should be taken into account. We have a portable device here, which is definitely a notorious change of place, frequent falls, but also a higher temperature inside, etc. It must be done safely and securely. The ways I found on the web are: use of glue, wide heat shrink tubing, welding, wrapping with tape. I must admit that welding looks the most reliable, but we must have a suitable (the same as the housing material) binder. And do it reliably. A different welding machine than one based on hot air - ultrasonic - rather, the average electronics engineer, amateur or even service technician does not have. At least not everyone. But definitely the worst the way I think is to use only electrical tape. Whatever it is, even the best will degrade over time, it will start to peel off due to constant movement, shifting, etc. It is worth mentioning that nowadays laptops (although similar power adapters are not only in them) are used by several-year-old children. And the children know. Curiosity and they are already starting to "scrape" that tape. A moment of inattention and they will be interested in what is in this black forest. The tragedy is ready! But of course not only children are at risk. Therefore, I believe that too many people underestimate this problem in this type of repair. Sometimes it is not worth the risk and if we are not sure about the safety, for many people it will be a much better choice, however, to buy a new power supply.

Let's remember:

CAUTION!! INCORRECT CONNECTION OF THE PLASTIC PARTS OF THE HOUSING RISK OF SHOCK!

I am counting on you and your ways here. Can it be connected solid, safely and securely, just like after leaving the factory?

Cool? Ranking DIY