Hi,

I am designing an ESP-based device with a fair number of inputs to which micro-switches will be connected. The electronics will be in a plastic enclosure, with a film on top through which the user will push the micro-switches. I want to protect these inputs in a professional manner, so that they are resistant to ESD, for example, if this is the case with the mechanics. I know ESP has some ESD protection, but I still want to add something of my own, as long as it doesn't harm....

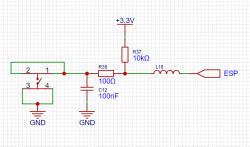

Below I am sending a schematic of one button that I made based on information I found on the forum:

1. pull-up to supply voltage

2. capacitor to ground in parallel with the button

3. a 100R resistor to eliminate contact vibration to some extent

4. choke with as little resistance as possible

.

.

What do you think of such input protection?

I would be very grateful for your help.

Regards M.

I am designing an ESP-based device with a fair number of inputs to which micro-switches will be connected. The electronics will be in a plastic enclosure, with a film on top through which the user will push the micro-switches. I want to protect these inputs in a professional manner, so that they are resistant to ESD, for example, if this is the case with the mechanics. I know ESP has some ESD protection, but I still want to add something of my own, as long as it doesn't harm....

Below I am sending a schematic of one button that I made based on information I found on the forum:

1. pull-up to supply voltage

2. capacitor to ground in parallel with the button

3. a 100R resistor to eliminate contact vibration to some extent

4. choke with as little resistance as possible

.

.

What do you think of such input protection?

I would be very grateful for your help.

Regards M.