Simple screwdriver stand for wall mounting - design and 3D printing

Hello my dears

Today I'm going to describe here my screwdriver organiser/stand/segregator that mounts on the wall.

I designed the whole thing first in the 3D modelling program Blender, and then printed it on a 3D Creality Ender Pro 3 using PLA filament.

Project ideas

The idea of such an organiser for screwdrivers is quite old and I myself have encountered it already in a wooden version, i.e. it was simply a board screwed to the wall and holes were made in it. But progress is moving forward, so I thought, why not print something like this for myself on a 3D printer? I decided to give it a try and gave myself the following assumptions:

- the model should be simple, without unnecessary additions

- model will be printed in ' Low Quality ' mode, that is the fastest one

- the model will have 10 screwdriver holes and two fixing holes

- the model will be made in Blender and will be made parametrically in Blender (i.e. I will be able to quickly change the number of holes and their size at any time, without having to edit each of the holes individually)

Element design

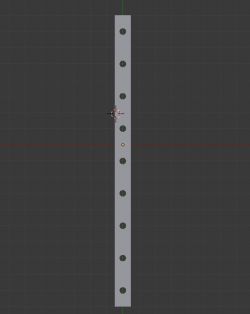

I started by designing the element in 2D. I assumed a hole spacing of 20 mm and a hole size of 5 mm .

The whole piece had dimensions 10 mm on 180 mm .

I also took the liberty of printing out a test piece, just for a live fitting. Specially one that is flat so as not to waste the filament. This sort of thing avoids any major/trivial errors getting into the final model.

After printing the above model (it only took 15 minutes to print!), I made the first fittings to my screwdrivers:

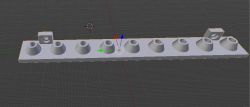

It came out pretty well, so I didn't actually make any big adjustments, just slightly resized the holes and started to develop the design. I added fixings, made it thicker, and extended the holes to make the screwdrivers hold solidly.

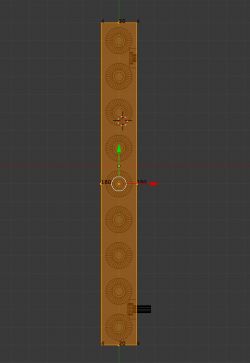

The final version of the piece looks as follows:

Additionally, I give a screenshot of the dimensions shown:

Print of the component

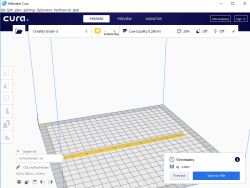

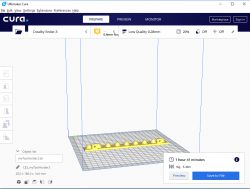

I imported the final model into Cura and started printing.

During the printing process, I observed that the 3D printer first applies a sort of border to the model (and the holes) and then only fills it in. Image is the photo below:

After less than two hours (according to the time estimate from Cura) the piece was ready. It came out like this:

It looks promising, but will it work? We are about to find out.

Final result Final result

In the end, I prepared the following kit for myself to assemble (printed piece-organiser, two screws, and screwdrivers):

I mounted the whole thing on a wooden wall in the workshop:

This is how the organiser already looks in use, along with a set of my torx screwdrivers (and a few others).

Summary, conclusions

I am very happy with the design. It is small, simple, and yet pleasing. As for improvements, I guess the only thing that could be done would be to extend those bushings of holes to make the screwdrivers hold more solidly in it, or make a version with two rows of holes.

The length of each piece is unlikely to be able to exceed 200mm in my case, as I am limited by the print area of my 3D printer ( Ender Creality Pro 3 ). Theoretically I could try after making the model to rotate it and align it diagonally, but I think the game is not worth the candle.

The organiser will certainly last me a long time, and even if by some miracle it gets damaged (which I doubt, the print is very solid and hard) I will just print it again.

For those interested, I am posting the source file with my model (in blend format):

Additionally I attach the same but already exported to STL format:

Comments

In my opinion, this is unfortunately a complete misunderstanding. How long does such a print take, what cost (including time spent on the project)? In order for the criticism to be substantive...Such things... [Read more]

Wait a minute, in the subject line you have all the information you need , you just have to read it all. The print time per piece is 1h 41 minutes and the weight per piece is 16 grams. Recently, a kilogram... [Read more]

Printing may be cool but in this case I would actually prefer to drill a piece of old board. The design can be drawn in tens of seconds and also duplicated indefinitely. A drill shouldn't use much electricity... [Read more]

As a project carried out to have fun with a 3D printer...cool. Better than printing dwarf figures. Unfortunately, however, I have to agree with the previous speakers that printing this type of "invention"... [Read more]

Easier and simpler to get out of the cable tray. But as an exercise it is ok. [Read more]

An interesting idea, of course more for the purpose of training the preparation of the design and the print itself. In addition, you get high aesthetics when comparing to a piece of wood or sheet met... [Read more]

The project doesn't kick ass, but that doesn't mean it didn't make sense. It's good that you've practiced and have more experience with the printer and projects. All I can do is wish you continued success!... [Read more]

As a training project I am of course in favour. However, I would think twice about continuing to equip the workshop with these types of prints. Well, unless under some distinctive tools that are hard to... [Read more]

Hello! On the mechanical side, I would also add supports between the two surfaces, the grommets for fixing on the wall and the slat itself. It will then not break even accidentally or due to material... [Read more]

And I understand the printer was given to a colleague as a gift for his birthday. [Read more]

And did you get a screwdriver and a drill or did you buy one ? Because those two things are the cost of a printer, unless you buy the cheapest sort. (Ba, I'm tempted to say something else, I'm assuming... [Read more]

The prices of printers are at such a level that many hobbyists can afford one to play with. So if something useful is created on it, rather than just toys, dumbwaiters and keyrings, that counts for a... [Read more]

SkechUp or ThinkerCad online [Read more]

SketchUp I recall - also used to come by default with Windows I think? Or maybe I installed some free version for myself.... I can't remember. About 8 - 10 years ago I was doing a visualisation of something... [Read more]

DesignSpark Mechanical, based on the Spaceclaim engine, only free. Pozr [Read more]

Fusion 360 [Read more]

It already depends... a well raked (no burrs, etc.) angle bar made of Al can look better = especially if you use an angle bar with oxidation in a colour (matching the shelf for example). Just go to OBI... [Read more]

And I'll just remind you some more, as this data is lost in the subject: Such a one 16-gram fart! Seriously? Very economical, very... Like nothing, only mass production to open :D [Read more]

Thanks for the hints. I'm a "layman" on the subject, so I approach all programs without prejudice. I'm using each one for the first time ever. As a test, I've thought of doing a winding staircase.... [Read more]