SMD drum containers from Thingiverse - my review and print test

Hello my dears

I recently found an interesting 3D printable object on the Thingiverse website and decided to do a short review of it here. I think the idea is quite good and worth promoting.

SMD Component Magazines by robin7331

All the information can be found on the model's author's page, on Thingiverse:

https://www.thingiverse.com/thing:3952021

This is a container for SMD components from which the end of the ribbon sticks out and we can gradually pull it out of the container and cut as much as needed. A very convenient and fresh concept compared to what I have seen before (also from us on the forum).

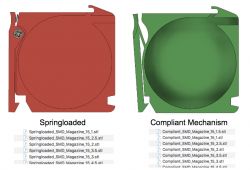

There are generally two types of container:

A stand for these containers is also included, along with holes for possible fixing. The containers also attach easily against the stand, using either a spring or the filament-based spring clip itself (known as 'compliant'). I have only tested it in the 'complaint' version and it works very well. The only thing you need to do is to clean the edges against which you hook this mechanism from any bumps, 'stringing' PLA.

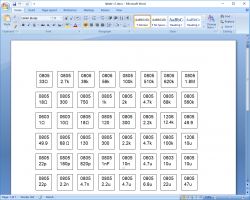

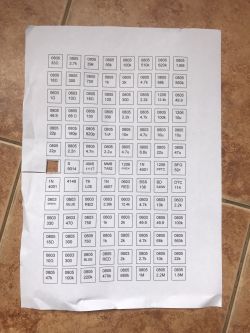

My template for labels

In order to sign the containers, I prepared myself a simple template in Word. There are squares of 15mm sides (when printed on A4 paper) into which you can write the abbreviated names of the items:

I printed the labels on ordinary A4 paper and stuck them to the containers with double-sided adhesive tape.

My printout

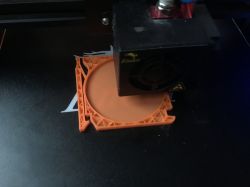

I used PLA filament for the project, or more accurately its leftovers from other prints. I printed on an Ender 3D Pro. I printed various sizes of 'compliant' containers. I always printed a width of 15mm (there is 'Magazine_15' in the name), but different gap heights (1mm, 2.5mm, 2mm etc).

I made the following observations while printing:

- these models are quite easy to print, I printed some with old leftover filament and despite the large stringing everything is OK

- the printing of these models can be accelerated a bit (if only by changing the Feed Rate already on the running Ender 3 with the knob)

- these models can be printed with a larger nozzle

During printing:

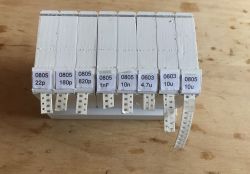

Individual boxes after printing:

Fitting:

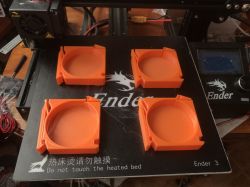

Printing four at a time:

Signature card:

Final version of the boxes on the stand (also included is a model of it):

By the way, those white and black boxes were printed from old filament (from leftovers from larger prints) and the orange ones were printed from new filament. You can see the big difference. Well, a man is a lifelong learner, and I will still polish these boxes.

Cost estimate

(added a little later at users' request)

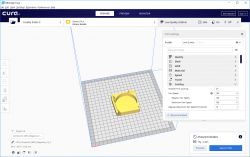

You can easily calculate how much one box costs us - its weight is estimated in Cura. 'Low Quality' mode and 0.4mm nozzle (larger nozzle will speed up the print):

This is the container I chose - 15mm wide.

I've also experimentally checked that this 2h print can be whittled down to as little as 1h (200% Feed Rate) and the object still comes out fine (although this also depends on the quality of the filament and the condition of the printer).

So we have:

- 20g weight (19g, but I rounded up for clarity of calculation)

- print time 1h

Now the question is what kind of filament. I use the cheapest one and it is quite OK. I pay £50 for 1kg, I buy exactly that:

(seller blurred because I don't like to do cryptic advertising).

From 1kg spool we have 1000/20 = 50 boxes for 50 zł + shipping of filament + electricity, so one box costs just over a zloty .

Pluses and minuses of the solution

After several weeks of use, I am able to list the following pluses of this solution:

+ very convenient access to the SMD component

+ everything is in view

+ containers are available for different SMD components

+ the 'compliant' mechanism based on the elasticity of the print is ingenious and works well

I also see some downsides:

- if we have very few components, these containers waste space (but I'm not likely to be affected by this, and if I have something small, I keep outside them)

- if the vendor sends us a cut SMD tape (it happened to me), then there is no way to put it inside this container in a sensible way

Attachments

Files from Thingiverse - I can give them here as they are under a Creative Commons licence:

My 15mm by 15mm label template in docx:

Summary

I really liked this type of container for SMD components. It is much better than the containers I have seen before (also on Elektroda) and I am already using it at the moment. The components can be removed easily and quickly.

What do you think of these containers? Do you know of any better alternatives?

Comments

As you yourself pointed out in the Pros and Cons, you should buy in tape. Admittedly it takes up more space than the bulk tape itself, but the convenience and use makes up for it in full. Cool in my opinion,... [Read more]

Super solution ! Could you write how much filament (grams) goes down for one such feeder ? Regarding alternatives : I store loose parts in sizes 0402 to 1206 in eppendorf tubes. They take up very... [Read more]

I like the idea itself, but I share the opinion of my colleague 398216 Removed , useful for the most used parts. Please have a look mate at the screenshot from Cura (posted by the author), there is... [Read more]

I updated the topic (added a paragraph about costs) after your message. Do I know, you could make a smaller version of these containers. Well, and you wrote the post before I gave the cost estimate. With... [Read more]

Not counting energy and time ;) But - you're right; for even £1.5 it's worthwhile. Still about the descriptions: If the box would be "assigned" permanently to a specific component, such adhesive paper... [Read more]

A newer version with special places for inserting labels is also available. No more searching for adhesive paper or gluing. The printout can be laminated, cut into individual labels and inserted. Durability... [Read more]

Yes, but only one size. [Read more]

Are you referring to the size of the SMD components/width? Moving the walls by a few mm is not a problem, if anyone needs other versions, let me know, I'll do it for you and upload the STL to the f... [Read more]

After all, the width of the SMD tape is standard, it's probably about the size of the label :) [Read more]

Actually, a better thought out design than the one in the title post ;) Greetings [Read more]

I may be exaggerating the accuracy, but even in the title photo: https://obrazki.elektroda.pl/5892331500_1596962396_thumb.jpg you can see that the width of the ribbon with 1N4001 is different from... [Read more]

I know, I should have written 'more refined' instead of 'rethought' ;) Greetings [Read more]

Well you see, indeed my mistake. [Read more]

The width of the tape is not standard. It is not the size of the label, but the thickness of the elements in the tape. There (if a colleague "missed it") is a slit through which the tape with the elements... [Read more]

After all, I apologised for the mistake. Is it not possible to make a mistake? [Read more]

There are several tape widths with SMD components but they tend to stick to standards. The project itself cool ! :) [Read more]

...Which ones? Do you know of any standards that regulate this? ;-) [Read more]

Hi. I have also noticed these containers at a company I know but fixed on long (about 1m) steel rods. At first glance one would like to have these but.... What about the 'tails'? After all, I'm not going... [Read more]

Look at Pick and Place machines e.g. Siemens Siplace. there are feeders in 8mm, 12mm, 16mm, 24/32mm sizes. [Read more]