Refrigerator compressor using 3D printing

Presenting a mini air compressor made by me using the unit from a refrigerator.

The heart of the compressor is the genset pulled from an old fridge, which due to corrosion was only suitable to be given away for scrap. The 24 L tank was given to me as a gift from a friend; it came from an oil compressor (model pictured).

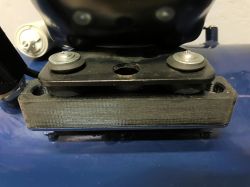

I started by designing the parts with which I mounted the unit in place of the original compressor, these are two plastic parts sized to fit the mounting holes on the tank and the unit. The adapters were printed with PLA filament on my modified Ender 5 printer.

The next printed item is a pressure switch cover to protect against electric shock. I got the pressure switch or pressure switch together with the tank from a friend.

What is interesting and worth noting is the way I implemented the introduction of compressed air into the tank. I didn't want to use any flexible hoses, worm ties etc. the connection had to be secure and reliable (leak-proof). The tube coming out of the unit is steel and 4.8 mm in diameter, the same as the brake pipes used in automotive applications, so I used a brake line connector without crimping.

Then there is an M10 coupler screwed in and a reduction from M10 to a standard 1/4 inch outlet. This created a very solid, secure and disconnectable connection between the unit and the rest of the compressor's pneumatic system.

I used an electro-valve and a non-return valve in the role of the de-stressor that enables the unit to start. When the compressor is pressurised to 8 bar, it switches off the unit and the NO-valve through which the liquid escapes between the non-return valve at the tank itself and the unit. This makes it possible to start up again without pressure in the fridge compressor. I did not use a regular pressure switch with a pressure relief valve because the one that came with the cylinder did not have this option and I did not want to change it.

On the outlet there is a standard pressure gauge in the tank, a regulator with dehydrator and pressure gauge and a quick pressure coupling. Such standard equipment on almost every compressor. In the tank itself, I also screwed in a new safety valve and a valve for draining the condensate.

I made all the electrical connections in the factory fridge box, fitted a rocker switch on top which switches the compressor and solenoid valve via a pressure switch. Of course I did not forget the earthing.

Below are the pictures and feel free to comment.

Comments

Do I see correctly that the air is taken in without a filter? What is the time it takes to inflate the tank from 0? In what pressure range does it operate (when does it turn on and when does it turn... [Read more]

How about switching the genset off and on. It was a problem for me, it had to be left on for a while, to cool down. It didn't do a great job, pumped a few times and then went out of service. It waits to... [Read more]

And I like this solution with the solenoid valve, it minimises the risk of the engine locking up on start-up due to pressure. I guess this is one of the few similar designs presented on the forum equipped... [Read more]

Nice kit . Can the author of the compressor post the connection diagram . Added after 41 : What is the stress reliever [Read more]

The solenoid valve that drains the pressure between the compressor output and the check valve. [Read more]

What about the oil from the compressor - it's not all submerged in oil and a drop at a time when pumping doesn't come out ? [Read more]

Older gensets had electromagnetic starting, not posistor starting. You could yes start as often as you wanted. [Read more]

Very nice project. The only thing I would add is that this compressor on r600a runs on vacuum so hence the need for a de-stresser, starting problems and severe heating. If a compressor on r134a or r22... [Read more]

I have such a two-piston pump in the compressor and it is no revelation. Yes it has a much higher capacity but after pumping a 60l tank to ~8 Bar it has to stand for a long time to cool down. Hermetic... [Read more]

For me, a compressor with oil in the air is not suitable for anything - not for painting and not for driving pneumatic equipment. no one is writing anything here about the dangers / emissions of chemical... [Read more]

After all, pneumatic equipment requires lubrication and such an oil mist suits them very well. Painting is a different matter, here you need a separator for both oil and condensation. [Read more]

I had no idea they were different. I've had some that needed to cool down. But you don't look a gift horse in the mouth ;-) . As for the oil mist, you used to give the oil separator in the form of a jar... [Read more]

The compressor pumps a 24L tank to 8.2 bar in 7.5 minutes. In the pressure switch operating range of 6 - 8.2 bar, it takes 2 minutes to re-pump. So far there is no inlet filter as I don't know what to... [Read more]

@kaeltaz You brag about using a 3D printer and so on, the housing and the chiller stand. And some kind of holder for the capacitor is missing and it's just holding on to the wires and dangling like that.... [Read more]

The lpg filter will catch dirt (if there is any) and oil until it is saturated with oil itself. The oil will not drain into the unit, only into the valves. To get it into the compressor, you would have... [Read more]

That's right, it won't be right away, but over time until the entire filter is covered with oil, and this oil on the filter will accumulate oil in the form of a mist already completely. Not quite... [Read more]

With the stubbornness of a maniac you insist on your own. I see that you have no idea how a refrigerator compressor is built. There are valves above the piston, and suction is taken from the crankcase,... [Read more]

He doesn't need to cut and peek, there is already an article describing the construction. [Read more]

@domelan I have a build like this to my credit and I know what I'm saying, at the time I hadn't applied it yet, it's been on the forum for 4 years and built another couple of years back. https://www.elektroda.pl/rtvforum/topic3521431.html And... [Read more]