Presenting a mini air compressor made by me using the unit from a refrigerator.

The heart of the compressor is the genset pulled from an old fridge, which due to corrosion was only suitable to be given away for scrap. The 24 L tank was given to me as a gift from a friend; it came from an oil compressor (model pictured).

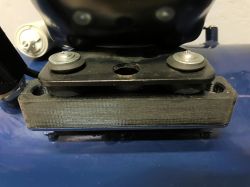

I started by designing the parts with which I mounted the unit in place of the original compressor, these are two plastic parts sized to fit the mounting holes on the tank and the unit. The adapters were printed with PLA filament on my modified Ender 5 printer.

The next printed item is a pressure switch cover to protect against electric shock. I got the pressure switch or pressure switch together with the tank from a friend.

What is interesting and worth noting is the way I implemented the introduction of compressed air into the tank. I didn't want to use any flexible hoses, worm ties etc. the connection had to be secure and reliable (leak-proof). The tube coming out of the unit is steel and 4.8 mm in diameter, the same as the brake pipes used in automotive applications, so I used a brake line connector without crimping.

Then there is an M10 coupler screwed in and a reduction from M10 to a standard 1/4 inch outlet. This created a very solid, secure and disconnectable connection between the unit and the rest of the compressor's pneumatic system.

I used an electro-valve and a non-return valve in the role of the de-stressor that enables the unit to start. When the compressor is pressurised to 8 bar, it switches off the unit and the NO-valve through which the liquid escapes between the non-return valve at the tank itself and the unit. This makes it possible to start up again without pressure in the fridge compressor. I did not use a regular pressure switch with a pressure relief valve because the one that came with the cylinder did not have this option and I did not want to change it.

On the outlet there is a standard pressure gauge in the tank, a regulator with dehydrator and pressure gauge and a quick pressure coupling. Such standard equipment on almost every compressor. In the tank itself, I also screwed in a new safety valve and a valve for draining the condensate.

I made all the electrical connections in the factory fridge box, fitted a rocker switch on top which switches the compressor and solenoid valve via a pressure switch. Of course I did not forget the earthing.

Below are the pictures and feel free to comment.

Cool? Ranking DIY