Hello,

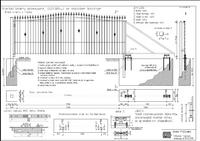

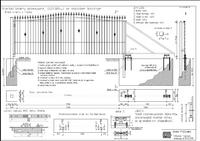

After dealing with the curve gate (my previous thread). It's time to assemble. And of course I have some questions how to do this. I wrote to the manufacturer and received fairly accurate assembly instructions:

However, not everything is clear to me:

1) How do I put these M16 foundation bolts (50cm long) in the trench? The excavation under the foot is planned to a depth of 120 cm. How is it done? On some rack? How to do so that nothing changes, etc.?

2) Another thing: "Before concreting the elements, carry out a trial assembly with checking for permeability"? As ? I will have a hole dug .. somehow I will put these bars .. screws .. how should I check if there is a big hole

3) I heard that many people supposedly poured foot .. and then drilled holes for bolts. I am just wondering to what extent is this a certain solution? What do you think about it ? (I mean, I assume that only the guide post is embedded in the foot)

thanks for any advice

Pawel [/ img]

After dealing with the curve gate (my previous thread). It's time to assemble. And of course I have some questions how to do this. I wrote to the manufacturer and received fairly accurate assembly instructions:

However, not everything is clear to me:

1) How do I put these M16 foundation bolts (50cm long) in the trench? The excavation under the foot is planned to a depth of 120 cm. How is it done? On some rack? How to do so that nothing changes, etc.?

2) Another thing: "Before concreting the elements, carry out a trial assembly with checking for permeability"? As ? I will have a hole dug .. somehow I will put these bars .. screws .. how should I check if there is a big hole

3) I heard that many people supposedly poured foot .. and then drilled holes for bolts. I am just wondering to what extent is this a certain solution? What do you think about it ? (I mean, I assume that only the guide post is embedded in the foot)

thanks for any advice

Pawel [/ img]