Good day. I need help choosing the diameter of the pp pipes in the water system. I am asking for advice.

1. From the main connection to the boiler

2. Cold supply to the riser

3. Power supply of hot to the riser

4. Circulation

5. Cold riser (bathtub, shower, washbasin, toilet on the first floor)

6. Heat riser (bathtub, shower, washbasin, toilet on the first floor)

7. Power supply of the basin battery

8. Powering the sink faucet

9. Toilet power

10. Washing machine power supply.

11. Floor shower supply

12th floor bathtub power supply

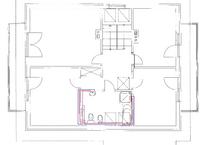

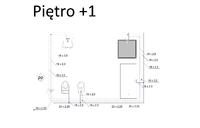

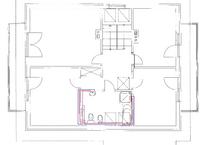

To illustrate the installation, I paste photos.

1. From the main connection to the boiler

2. Cold supply to the riser

3. Power supply of hot to the riser

4. Circulation

5. Cold riser (bathtub, shower, washbasin, toilet on the first floor)

6. Heat riser (bathtub, shower, washbasin, toilet on the first floor)

7. Power supply of the basin battery

8. Powering the sink faucet

9. Toilet power

10. Washing machine power supply.

11. Floor shower supply

12th floor bathtub power supply

To illustrate the installation, I paste photos.