Hello.

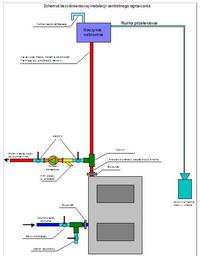

I am asking specialists for advice on where to install the pump for central heating in an open system on the supply or return, because the stove will be in the kitchen and the pipes for the radiators would go horizontally under the ceiling and up under the radiators. Ceiling with a thickness of about 0.5m.

Will the pump cope with the power supply?

Should it be mounted on the return?

I am asking specialists for advice on where to install the pump for central heating in an open system on the supply or return, because the stove will be in the kitchen and the pipes for the radiators would go horizontally under the ceiling and up under the radiators. Ceiling with a thickness of about 0.5m.

Will the pump cope with the power supply?

Should it be mounted on the return?