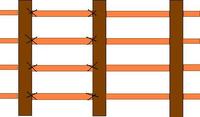

Such stiffening of the ceiling is done differently.

I don't know why everyone is blindly following the direction of the floor beams.

If you add an additional beam (steel or wood), the beams will work independently anyway, which is what causes the tiles to crack.

The floor beams you have there are sure to give you sufficient strength and you should rely on them, and stiffening the floor (s) is another matter.

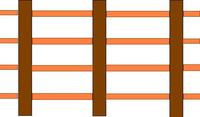

For the tiles, you need to create a uniform and rigid board based on the beams that are already there.

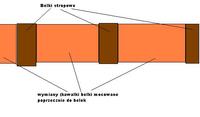

It needs to be strengthened (stiffen with beams in pieces.

Oh yes, beams in pieces.

Such pieces when used properly give the same as an entire extra beam.

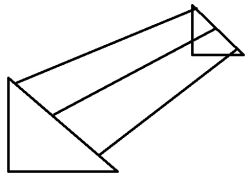

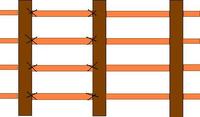

I will try to make a drawing of a cross-section of such a stiffener.

At construction sites, something like this is practically done on a daily basis to stiffen the ceiling.

In the case of new ceilings, only 2-3 rows of replacements are made, which are made of waste pieces of beams.

Added after 25 [minutes]: The following method, in addition to stiffening the ceiling, provides additional support points for panel joints.

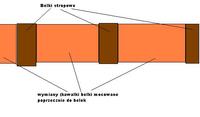

These exchanges do not have to be as thick as the ceiling joists, 4-5 cm is enough, but the height should be min. 2/3 of the height of the ceiling joists.

Fasten preferably with screws, but nails hammered in alternately in different (opposite) directions (angles) give similar results. see figure 4.

The replacements should be cut at an angle of 90 degrees, but you know, the old ceiling is slightly sagging and the beams are slightly twisted, so you mainly need to make sure that the ends of the replacements adhere to the ceiling joists at the top and bottom, without gaps.

Added after 2 [hours] 6 [minutes]:

Added after 2 [hours] 6 [minutes]: jawoks wrote: It seems to me that the 80x80 closed profile will be stronger than the I-beam 80. Generally, I mean, let someone count the "deflection arrow" of this beam (I get strange results when I go for it) or say from experience that this beam is 4m will not bend under the weight of a person.

A 100mm I-section with a span of 4m will have a deflection of about 12mm, which is more than a 22mm deflection of a plate, over a span of 80cm between the beams.

Such a board needs a support of at least 60cm and 40cm. that is, if it is supported every 60 cm along its width, it must be supported every 40 cm along its length. I have already seen such boards supported reasonably well and a thin leg of a heavy piece of furniture passed right through it.

Besides, how do you want to fix the wood (boards) to steel, with glue?

You're going to get a messier than you expect. Steel works differently than wood and the effect on the tiles will be worse than without it.

A quicker and rather moderately good way is to use a flexible transition between the plate and the tiles (eastern glue), point gluing, and tiles of small dimensions, as well as givelarger than typical widths of the joints, which will reduce (spread) most of the stresses, but will not eliminate them completely.

The support of the disc must be one way or another, only these replacements did not have to be that high.

It is your decision, there is always something for something. The lower the quality of the stiffening, the greater the risk of damaging the tiles.

You will make the stiffening solid, the plate will have good support and the plates will not crack.