Hello and best regards to all readers of this website.

After a long time of working and listening, I decided to place this project on the electrode. The project is interesting because I made many mistakes during its creation and it is a pity for me not to share these experiences with others. This project should be treated a bit as a warning / set of comments / experiences, and maybe even a warning against too rash taking action without prior substantive preparation.

Project - preparation and assumptions

At the beginning it was supposed to be a simple design, the only assumption of which was the width of the column: max 17/18 cm. This is due to the fact (as can be seen in the photos) that a wider column would block my exit to the balcony.

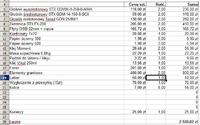

From previous projects I had a few speakers on the basis of which I decided to build this set (ERROR 1 - randomly selected speakers) : and they were:

- TONSIL-GDN-25-80-1

- STX-GDM-14-150-8-SCX

- STX-GDWK-10-250-8-AWX (currently T.10.250.8.PCX)

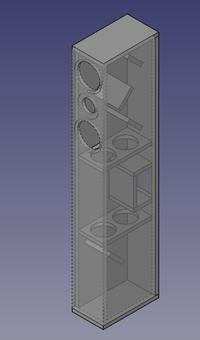

The housing was supposed to be closed with a capacity of 35l (and it remained so). the medium speaker chamber is about 4.5l. As the midrange and tweeter speakers coincided with the STX FX-200 set, I decided to commit too ERROR 2 - so I bought a dedicated crossover just for the STX FX-200 loudspeakers .

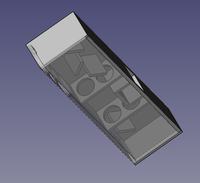

Granite fronts and the side of the column were an additional assumption. The elements shown in the photos are made of real granite. I ordered them from an establishment that makes tombstones

The decision to use granite to build columns results from my love for natural and solid materials (it did not necessarily translate into sound quality - another small one [BUG]) ...

Armed with speakers, crossovers, boards and other materials, I decided to put it all together. The construction process was as shown in the photos below.

Construction photos

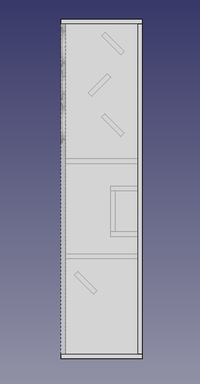

Version number 1 columns

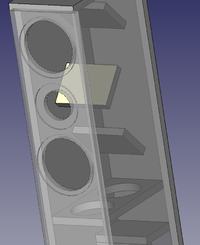

After the construction was completed, the columns looked like this:

The loudspeakers looked like in the photos ... maybe even nice. Unfortunately, they played hopelessly. Their terrible sound was due to several things and the main reason for this was the placement of the woofer on the side, not using a sufficiently low division on the crossover [ERROR 3] .

It wouldn't even be such a big problem if it wasn't for the fact that the midrange driver is only a mid-range speaker and not a midwoofer [ERROR 4] .

And what to do with it next?

Unfortunately, the ill-thought-out design has already been closed, assembled, soldered and glued .. There was no large room for maneuver and the advice of specialists was unambiguous (thank you again, colleague Tomq): post . I started to figure out and build my own crossover. I armed myself with the holmImpulse program, microphones, resistors, capacitors, wire and a room.

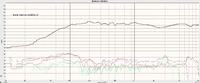

The results of the measurements were, however, poor ... Poor because the graphs turned out to be perfect - just the perfect characteristics of the loudspeakers. Unfortunately, the ear did not allow you to believe what the eye saw on the chart

So without going into further details of the measurements - because it already took me a lot of time and the speaker hobby began to take more and more of it, the prospects for a quick completion of the project were not optimistic and the lack of knowledge was still gigantic. Also, the costs incurred for the construction of the columns were not low and the granite fronts were hardly modifiable

The new life of the project, i.e. version number 2

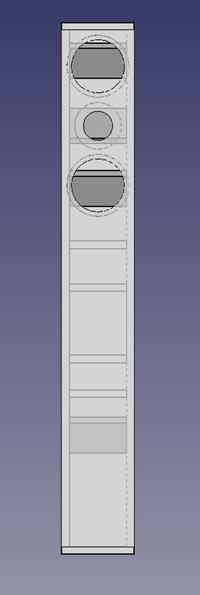

After taking measurements with appropriate equipment and in appropriate conditions, the verdict was as follows: "in a word, a massacre! Nice housing, but it will be difficult to do something about it" .... However, I managed to convince your specialist to do anything with it Such a tragedy ... He did not have much room for maneuver because the above-mentioned granite fronts did not allow for free exchange of transducers. The biggest problem was the mid-woofer, in the place of which it was necessary to insert a mid-woofer - unfortunately, the milling cutter made of granite significantly limited the possibilities of choosing something that has arms and legs ... After several days of searching, there was a speaker at a reasonable price and matching for carved holes. Is it FW-146 .

The next step was to make a new crossover so that the woofer placed on the side of the loudspeaker would play 150Hz max and the other two began to harmonize with each other.

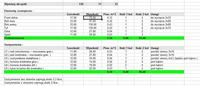

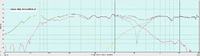

After quite a long fight with my speakers, we managed to do something about the acoustic effect as shown in the pictures below:

Graphs / Measurements

Harmonic distortions

A: impulse

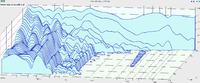

Waterfall

The whole column

Apart from the new crossovers, the loudspeakers got new terminals, better soundproofing of the mid-woofer and additional soundproofing of the main chamber, as well as new cabling.

And that's it ...

End of the project and conclusions

Ultimately, I made a decision that I would not assemble any more speakers myself (in the sense without the help of a specialist). This decision is made up of the following factors:

- I do not have sufficient skills and acquiring them requires a lot of time and practice.

- I do not have a measuring base or sufficient knowledge to test the loudspeakers by myself.

- The sound of the speakers after modification in comparison to my other works of art causes a quality gap.

Of course, the hobby will remain and there will certainly be a few more constructions. However, each subsequent construction will be better prepared and thoughtful.

Finally, the columns look like in the pictures below:

I am generally satisfied with the loudspeakers, although their construction cost was 3 times more than it should have been. Granite fronts and 22mm plate were an exaggeration for the unnecessarily purchased STX crossovers, not to mention ...

The sound of the loudspeakers is certainly better (at least for me) than in the case of the Altus copy, which I also own. It seems to me that the midrange is a bit lacking (maybe it's the fault of the aluminum diaphragm) - the speakers make up for it with the precision of the sound, which I like very much. However, I know that it can be better, which is why I am already preparing for the next project. I hope there will be a lot less errors this time :-)

Minor remarks for other designers:

1. OSB is not a bad material for building a column, unfortunately it is terribly inconvenient to work with. I chip off large pieces of the board that need to be repaired many times. Sanding the veneer at the edges is also not made easier.

2. Never stick cables to the sides of the housing. Even though everyone is writing about minimizing the length of the audio path, don't regret giving the cables 50cm of slack. Later, working on a closed column becomes a nightmare. Soldering the cables in the center of the column hurts (actually burns).

3. Making a column that weighs 40 kg is also not a good idea. Especially when you have to lift them later from the 4th floor by stairs

4. The time, work and dedication put into building the loudspeakers will not repay the sound quality if the electrical design sucks ...

Cool? Ranking DIY