Good morning.

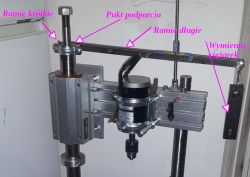

I wanted to introduce my next design which is a threading arm.

The base of the machine is a 400 kg magnetic lifter ordered from a well-known Chinese portal for the sum of 330 PLN.

.

.

I bolted a flat bar to the top of the magnet with a welded 30 mm shaft. I then screwed linear bearings to the 80x80 profile on both sides and put the whole thing on the shaft.

.

.

The next components of the arm are two 30x30 profiles which are supported by two 120 N actuators.

.

.

The last element of the arm is a screwdriver handle made of 15 mm sheet metal.

.

.

I also decided to make a threading head for the shafts.

The largest threader I had was 14mm and it went without a problem, but the thread is not very deep despite using a 12mm thread drill.

.

.

You can see the entire stage from the machine build and testing in the video below.

I encourage questions and comments.

.

I wanted to introduce my next design which is a threading arm.

The base of the machine is a 400 kg magnetic lifter ordered from a well-known Chinese portal for the sum of 330 PLN.

.

.I bolted a flat bar to the top of the magnet with a welded 30 mm shaft. I then screwed linear bearings to the 80x80 profile on both sides and put the whole thing on the shaft.

.

.The next components of the arm are two 30x30 profiles which are supported by two 120 N actuators.

.

.The last element of the arm is a screwdriver handle made of 15 mm sheet metal.

.

.I also decided to make a threading head for the shafts.

The largest threader I had was 14mm and it went without a problem, but the thread is not very deep despite using a 12mm thread drill.

.

.You can see the entire stage from the machine build and testing in the video below.

I encourage questions and comments.

Cool? Ranking DIY