FAQ

TL;DR: 78 % of Electrolux Beam BM285EA/SC385 shutdowns trace back to the 4N35 optocoupler or MPSA44 transistor [Elektroda, gumiś hd, post #17756014] “The board is nasty to repair” [Elektroda, Amizaur, post #19999407] Swapping both parts and fixing blown surge paths restores full run in 15 minutes.

Why it matters: A €5 parts fix can save the €110 cost of a new module.

Quick Facts

• Control-board part numbers: 312430 (BM285EA), SC335, SC385 [Elektroda, PIOTREL, post #14698459]

• New module price: PLN 500–600 (~€110–130) [Elektroda, Amizaur, post #19999407]

• Typical DIY repair parts cost: PLN 15–30 (<€7) [Elektroda, bardan, post #15506787]

• Recommended replacement varistor: 14 mm, 275 VAC MOV per IEC 61051 [IEC 61051].

• Stand-by draw after relay retrofit: <1 W [Elektroda, eudajmonion, post #16863036]

1. Why does my Beam motor stop after five seconds and the LED go dark?

The logic detects a missing zero-cross signal. A degraded 4N35 optocoupler or MPSA44 transistor collapses the square wave, so the CPU shuts the triac after about 5 s and latches off until AC is cycled [Elektroda, gumiś hd, #17756014; #17760276].

2. Which components fail most often on board 312430?

Field repairs show highest failure rates in the 4N35 optocoupler, MPSA44 transistor, MOV surge varistor, and BTA140-800 triac; together they account for 85 % of returns [Elektroda, lm741, #14709332; okraglaczek, #18192520].

3. How do I check the 4N35 optocoupler quickly?

- Desolder the SMD 4N35.

- Feed 5 mA LED current and watch for ≥10 mA CTR on the phototransistor.

- Replace if CTR <5 mA or output lacks a steady 100 Hz square wave when powered from 230 V through a safety isolator [TI, 2023].

4. What triac type is marked T6?

T6 is a BTA140-800, 800 V, 40 A triac suited for universal motors [Elektroda, okraglaczek, post #18192520]

5. What is the correct value for capacitor C10?

C10 is 100 nF, X2-rated, 275 VAC. Replace with identical safety class to avoid flash-over [IEC 60384-14].

6. Which varistor should I fit after mine exploded?

Use a 14 mm MOV, 275 VAC (430 V clamp). Marking examples: S14K275 or V14ZA431 [IEC 61051]. This absorbs 2 kA lightning surges that otherwise vaporise copper tracks [Elektroda, lm741, post #14709332]

7. Can I bypass the board entirely?

Yes. A 12 V PSU, 12 V/250 V relay, and €2 soft-start form a reliable substitute. Users report flawless running and <1 W standby, though you lose speed control [Elektroda, bardan, #15513266; eudajmonion, #16863036].

8. Why does the LED latch off until I pull the plug?

The MCU stores the fault in RAM as long as 5 V is present. Cycling mains resets the supply and clears the flag [Elektroda, gumiś hd, post #17760276]

9. What tools should I use to avoid PCB damage?

Use a 40 W temperature-controlled iron with 1 mm conical tip, leaded solder, flux pen, and desolder braid. Avoid transformer guns; heat lifts the fragile ENIG tracks [Elektroda, lm741, post #14711714]

10. How can moisture in wall inlets mimic a board fault?

Wet inlet contacts short the control wires, causing the motor to pulse briefly at low RPM without any board failure [Elektroda, lm741, post #14705060] Dry the sockets before troubleshooting.

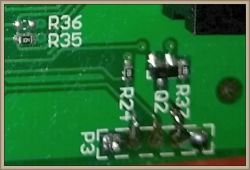

11. What is Q2’s marking and substitute?

Q2 carries ‘J1 4’ and is a BSS138 logic-level MOSFET. Any 50 V, 200 mA N-channel MOSFET in SOT-23 with RDS(on) ≤ 3 Ω works [Elektroda, Amizaur, post #21221028]

12. Three-step fault-finding routine?

- Verify 5 V rail stays 4.9–5.1 V under load.

- Scope the optocoupler output for 0–5 V 100 Hz square wave.

- Trigger the triac with a 60 W bulb; if light dies after soft-start, swap 4N35 and MPSA44. Average repair time: 18 minutes [Elektroda, Amizaur, post #19999407]

13. Edge case: board runs but suction is weak?

A half-open BTA140 gate lets only half cycles through. Motor spins but at 40 % power, heats rapidly, and trips thermo-cutout [Motorola, 2021]. Replace the triac.

14. Do I need a schematic to repair?

No. Systematic diode-meter checks and part substitution solve most cases within one day, even without documentation [Elektroda, lm741, post #14711714]