I am thinking about choosing cables for my equipment (no matter what for this topic)

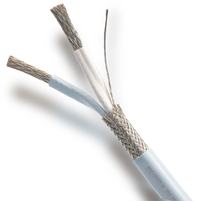

I am not a professional in this field, but I have reviewed several opinions that it is not worth investing in OFC cables because there is no difference compared to CCA.

And here the question arises, because CCAs are a bit cheaper (they are not a lot of money, but why overpay)

I do not know myself so I am asking for simple answers

Here is what interests me

http://www.avstore.pl/kabel-jack-2rca-wireway-5m.html

Many thanks for the tips!

I am not a professional in this field, but I have reviewed several opinions that it is not worth investing in OFC cables because there is no difference compared to CCA.

And here the question arises, because CCAs are a bit cheaper (they are not a lot of money, but why overpay)

I do not know myself so I am asking for simple answers

Here is what interests me

http://www.avstore.pl/kabel-jack-2rca-wireway-5m.html

Many thanks for the tips!