Hello,

when inspecting the suspension and chassis in the mazda I noticed a strange symptom.

If I tear the element of the "hinge" behind the support of the right drive shaft (from the wheel side), I sense that there is radial clearance (about 3-5 mm).

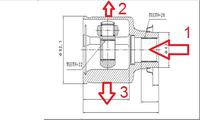

I didn't take a photo so I mark with red arrows on the photo found on the web:

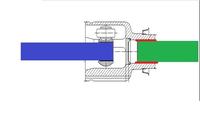

This does not look like a loose bearing, because the shaft going from the support to the crate does not move.

Is there a spline there and may be loose on it?

when inspecting the suspension and chassis in the mazda I noticed a strange symptom.

If I tear the element of the "hinge" behind the support of the right drive shaft (from the wheel side), I sense that there is radial clearance (about 3-5 mm).

I didn't take a photo so I mark with red arrows on the photo found on the web:

This does not look like a loose bearing, because the shaft going from the support to the crate does not move.

Is there a spline there and may be loose on it?