FAQ

TL;DR: For Lombardini LDW/LDW502 valve set-up, bring one cylinder to TDC, adjust, then "rotate the crankshaft 180°" and set the other; both valves use the same clearance. [Elektroda, Orochimaru, post #16652484]

Why it matters: This FAQ helps DIYers fix hard-start, rough-idle, and valve-noise issues on 2‑cyl Lombardini diesels fast.

Quick Facts

- Typical valve clearance seen by users: 0.15–0.20 mm; heavier-duty installs tend toward 0.20 mm. [Elektroda, sebastian1260, post #16655885]

- Adjustment sequence: pick any cylinder at TDC with both valves closed; set clearances; turn crank 180° for the other. [Elektroda, Orochimaru, post #16652484]

- Valve cover fasteners: cross-pattern from center outward is acceptable per community practice. [Elektroda, Orochimaru, post #16655761]

- Fuel rail service: replace four O‑rings during reassembly to prevent leaks. [Elektroda, sebastian1260, post #16655885]

- After opening fuel system, prime with a hand pump; first start may take longer to fire. [Elektroda, Orochimaru, post #16659755]

Which cylinder is “first” when adjusting valves on a Lombardini 2‑cyl?

Either cylinder can be first. Set a cylinder at TDC on compression so both valves are closed, adjust, then rotate the crankshaft 180° and adjust the second cylinder. “The clearance value is the same for both valves.” [Elektroda, Orochimaru, post #16652484]

How do I find TDC (Top Dead Center) for adjustment on this engine?

Turn the crank until the chosen cylinder’s cam lobes point away from the rockers so no valve opens. That indicates TDC compression for that cylinder. Adjust there, then rotate 180° to set the other cylinder. [Elektroda, Orochimaru, post #16652484]

What valve clearance should I use—0.15 mm or 0.20 mm?

Use the value specified for your application. Owners report 0.15 mm as the Lombardini spec, and 0.20 mm where the engine sees heavier loads, such as quads. [Elektroda, sebastian1260, post #16655885]

Is the clearance the same for intake and exhaust valves?

Yes. Community guidance for this engine notes the same clearance for both intake and exhaust valves during adjustment. [Elektroda, Orochimaru, post #16652484]

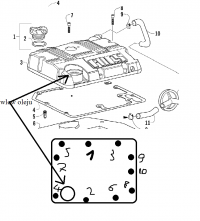

What bolt‑tightening order should I follow for the valve cover?

Tighten from the center outward in a cross pattern. The order shown by the user is acceptable and matches common practice on these covers. [Elektroda, Orochimaru, post #16655761]

Do I need a torque wrench for the fuel rail/cover reassembly?

A torque wrench is best, but users report success tightening evenly in stages by hand. Work all fasteners progressively to equal feel to avoid leaks or distortion. [Elektroda, Orochimaru, post #16657693]

How do I bleed the system after removing the fuel rail?

Reassemble with new O‑rings, then prime using a manual pump. Expect extended cranking on first start as fuel purges through the injectors. [Elektroda, Orochimaru, post #16659755]

How many O‑rings are on the fuel rail, and should I replace them?

There are four O‑rings on the rail in the discussed setup. Replace all four during reassembly to minimize seepage and air ingress. [Elektroda, sebastian1260, post #16655885]

Where are the glow plugs on LDW engines like 502/702?

On LDW702 they sit under the intake manifold; owners suggest LDW502 is similar. Remove the intake to access and replace the plugs. [Elektroda, sebastian1260, post #17459985]

My Lombardini starts cold but cranks long when warm. How can I set the injection pump?

Verify the pump control linkage. One owner restored proper starting by moving the pull rod on the injection pump to the maximum right position. Adjust carefully and test. [Elektroda, drajwer12, post #17341216]

Do injection pumps interchange between Lombardini models?

Compatibility varies. Confirm by cross‑checking the official parts catalog for your exact engine code before swapping components. [Elektroda, sebastian1260, post #17459985]

What torque should I use for LDD/LDW502 cylinder head bolts?

Consult the factory service manual for your specific variant. Community responses direct owners to the official manual for head bolt torque and sequence. [Elektroda, carrot, post #17284333]

What does TDC mean, in simple terms?

TDC, or Top Dead Center, is when the piston reaches the highest point in the cylinder. For valve setting, use TDC on the compression stroke when both valves are closed. [Elektroda, Orochimaru, post #16652484]

Is a 0.05 mm difference in clearance a big deal?

Users report 0.05 mm difference as not critical. For engines under heavy load, choose the slightly larger end of the typical range. [Elektroda, Orochimaru, post #16655761]

How do I set valve clearance on a Lombardini twin—quick steps?

- Set Cylinder A at TDC compression (both valves closed) and adjust its clearance.

- Rotate the crankshaft 180°.

- Set Cylinder B at TDC compression and adjust its clearance. [Elektroda, Orochimaru, post #16652484]

After reassembly, it still won’t fire—what’s an edge case to check?

Air in lines after opening the fuel system can delay firing. Keep priming and cranking; first ignition may take several attempts. [Elektroda, Orochimaru, post #16659755]