Hello!

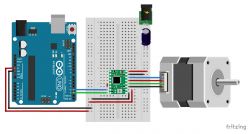

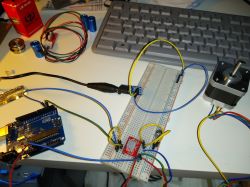

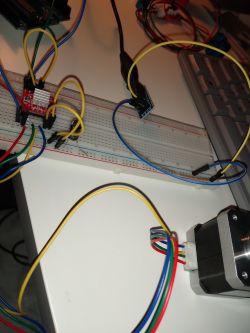

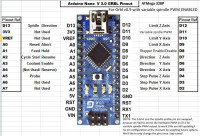

Recently I bought these NEMA 17 0.51 Nm engines

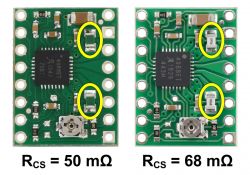

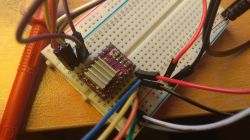

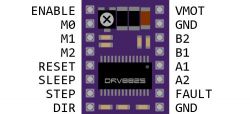

And the Stepstick RAMPS A4988 RepRap driver

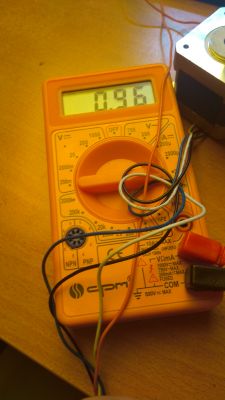

Engine control works but not exactly as it should. The engine squeaks and vibrates terribly during operation (unless this is the first time I have such an engine in my hands ). It's spinning very slowly even though it was supposed to spin at a fairly high speed. Anyone know how to speed it up and eliminate this squeaking and vibrations?

). It's spinning very slowly even though it was supposed to spin at a fairly high speed. Anyone know how to speed it up and eliminate this squeaking and vibrations?

Code (example from some page):

[syntax=c]// --- Commande d'un StepStick/Driver A4988 ----------------------

// A4988_Test.ino

//

// Commande d'un moteur pas-à-pas à l'aide d'un pilote A4988 avec

// Arduino.

//

// Un projet www.mchobby.be (vente de kit et composant)

// Meurisse D. - Licence CC-SA-BY

//

// Un tutoriel http://mchobby.be/wiki/index.php?title=A4988

// Ou Acheter un StepStick A4988

// http://shop.mchobby.be/product.php?id_product=349

//

#define pinEnable 4 // Activation du driver/pilote

#define pinStep 3 // Signal de PAS (avancement)

#define pinDir 2 // Direction

void setup(){

Serial.begin(9600);

Serial.println("Test A4988");

pinMode( pinEnable, OUTPUT );

pinMode( pinDir , OUTPUT );

pinMode( pinStep , OUTPUT );

}

void loop(){

int i = 0;

digitalWrite( pinDir , HIGH); // Direction avant

digitalWrite( pinStep , LOW); // Initialisation de la broche step

// Avance de 200 pas

for( i=0; i

Recently I bought these NEMA 17 0.51 Nm engines

And the Stepstick RAMPS A4988 RepRap driver

Engine control works but not exactly as it should. The engine squeaks and vibrates terribly during operation (unless this is the first time I have such an engine in my hands

Code (example from some page):

[syntax=c]// --- Commande d'un StepStick/Driver A4988 ----------------------

// A4988_Test.ino

//

// Commande d'un moteur pas-à-pas à l'aide d'un pilote A4988 avec

// Arduino.

//

// Un projet www.mchobby.be (vente de kit et composant)

// Meurisse D. - Licence CC-SA-BY

//

// Un tutoriel http://mchobby.be/wiki/index.php?title=A4988

// Ou Acheter un StepStick A4988

// http://shop.mchobby.be/product.php?id_product=349

//

#define pinEnable 4 // Activation du driver/pilote

#define pinStep 3 // Signal de PAS (avancement)

#define pinDir 2 // Direction

void setup(){

Serial.begin(9600);

Serial.println("Test A4988");

pinMode( pinEnable, OUTPUT );

pinMode( pinDir , OUTPUT );

pinMode( pinStep , OUTPUT );

}

void loop(){

int i = 0;

digitalWrite( pinDir , HIGH); // Direction avant

digitalWrite( pinStep , LOW); // Initialisation de la broche step

// Avance de 200 pas

for( i=0; i