Hello everyone, after the first tests

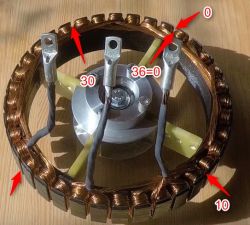

IVECO 28V 90A alternator.

After dismantling the rectifier bridge, a nice surprise, the stator windings are wound with double wire. I connected them in series, thus increasing the operating voltage from 28 to 56V.

Compared to the first alternator (even though I considered it a strong motor), the difference is huge. It is much stronger, faster, less power-hungry and more pleasant to the ear.

Idle current on full gas and the controller set to 100% filling:

-star- 0.6A

-triangle-1.3A

After 20 minutes of such fun, including braking the pulley, the alternator is very cold - even icy (you have to make a lot of effort to brake it a little and force it to draw electricity, I barely managed to get 16A ...).

Some people are probably wondering why I am continuing this topic. Well, I have been observing the topics of unconventional drives for a very long time. The topics of alternators are often discussed. Unfortunately, the vast majority of such posts are theory and stormy discussions that cut off the topic at some point. I am a curious person, so I gathered all the internet knowledge that I found into a single whole and decided to test it in practice.

My observations:

- the alternator should under no circumstances be excessively rolled. The result of excessive oversaturation is a sudden, very large increase in current consumption, a drop in efficiency and a very rapid increase in temperature (This is probably the oversaturation effect of the poor quality iron used to build the stator). The effect disappears when the voltage is reduced to the rated voltage.

-model controllers are not very suitable for continuous operation, let alone starting under load. Additionally, when the speed is too low in relation to the load, they simply cut off the power.

-powering the rotor directly from the battery: the most optimal in both cases for me is half the rated voltage of the alternator.

- powering the rotor with a voltage-reducing converter: in my case it didn't work out very well. Burnt 4 despite filtering noise from the rotor. Separation by both diodes and filters works well.

That's it for the time being. Hope I didn't get bored. If anyone has any questions, doubts, or test suggestions, I will be happy to listen to you and check how it looks in practice. If you need any notes or photos from my experiments, I will be happy to share.

IVECO 28V 90A alternator.

After dismantling the rectifier bridge, a nice surprise, the stator windings are wound with double wire. I connected them in series, thus increasing the operating voltage from 28 to 56V.

Compared to the first alternator (even though I considered it a strong motor), the difference is huge. It is much stronger, faster, less power-hungry and more pleasant to the ear.

Idle current on full gas and the controller set to 100% filling:

-star- 0.6A

-triangle-1.3A

After 20 minutes of such fun, including braking the pulley, the alternator is very cold - even icy (you have to make a lot of effort to brake it a little and force it to draw electricity, I barely managed to get 16A ...).

Some people are probably wondering why I am continuing this topic. Well, I have been observing the topics of unconventional drives for a very long time. The topics of alternators are often discussed. Unfortunately, the vast majority of such posts are theory and stormy discussions that cut off the topic at some point. I am a curious person, so I gathered all the internet knowledge that I found into a single whole and decided to test it in practice.

My observations:

- the alternator should under no circumstances be excessively rolled. The result of excessive oversaturation is a sudden, very large increase in current consumption, a drop in efficiency and a very rapid increase in temperature (This is probably the oversaturation effect of the poor quality iron used to build the stator). The effect disappears when the voltage is reduced to the rated voltage.

-model controllers are not very suitable for continuous operation, let alone starting under load. Additionally, when the speed is too low in relation to the load, they simply cut off the power.

-powering the rotor directly from the battery: the most optimal in both cases for me is half the rated voltage of the alternator.

- powering the rotor with a voltage-reducing converter: in my case it didn't work out very well. Burnt 4 despite filtering noise from the rotor. Separation by both diodes and filters works well.

That's it for the time being. Hope I didn't get bored. If anyone has any questions, doubts, or test suggestions, I will be happy to listen to you and check how it looks in practice. If you need any notes or photos from my experiments, I will be happy to share.