Hello to all forum members.

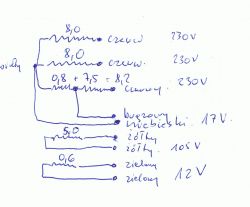

I have a 3-phase Kraft & Dele KW 6500 generator, Chinese for 700 PLN, of course, since it was new it was neither overloaded nor badly stored (in the rain, etc.), after some time it simply stopped working, I took it apart, actually the generators themselves, it turned out the AVR module is damaged, because when I connect the regulated power supply to the rotor (AVR completely disassembled), at approx. 21 V excitation voltage on all 3 sockets, it gives 230 and 400 for 3-phase nicely. I bought a new module on alledrogo, identical in appearance, only instead of blue wires it had green and the capacitor instead of 220 uF had 470, immediately after connecting and starting the aggregate it literally burned after 15-20 seconds, I complained about it, replaced it with a new one, , but only the ankle, the pins from the excitation hung loose because I wanted to check the polarity and voltage that the AVR gives, I connected the power supply for excitation, and again the same, the AVR is burnt. I picked out the resins from both, both burned plates in the same place, does anyone have any idea why this is happening? I will add that on the ankle, after starting the generator with a power supply, the voltages are 16 V on one pair of pins and 105 V on the other, i.e. 16 is probably. module and 105 is the reference voltage, right? I am adding photos, and can anyone tell which bridge on the avr board should nap. while. and for which nap. comparative? because when I called the Kraft Dele service, some technician from them said that it can be different in Chinese, they could even change the order of the wires in the cube, and the cubes cannot be inserted the other way around. I am asking for help, thank you in advance, best regards.

I will add that in both modules the yellow wires go to the bridge from the S2M diodes (1000V / 3A) and the green (blue) to the M7 diodes (1000V / 1A), the question which should be 105V and 16V, is the module on because of the voltage are replaced or for another reason, but when the generator was new it worked, and now it works without avr only on the power supply ...

I have a 3-phase Kraft & Dele KW 6500 generator, Chinese for 700 PLN, of course, since it was new it was neither overloaded nor badly stored (in the rain, etc.), after some time it simply stopped working, I took it apart, actually the generators themselves, it turned out the AVR module is damaged, because when I connect the regulated power supply to the rotor (AVR completely disassembled), at approx. 21 V excitation voltage on all 3 sockets, it gives 230 and 400 for 3-phase nicely. I bought a new module on alledrogo, identical in appearance, only instead of blue wires it had green and the capacitor instead of 220 uF had 470, immediately after connecting and starting the aggregate it literally burned after 15-20 seconds, I complained about it, replaced it with a new one, , but only the ankle, the pins from the excitation hung loose because I wanted to check the polarity and voltage that the AVR gives, I connected the power supply for excitation, and again the same, the AVR is burnt. I picked out the resins from both, both burned plates in the same place, does anyone have any idea why this is happening? I will add that on the ankle, after starting the generator with a power supply, the voltages are 16 V on one pair of pins and 105 V on the other, i.e. 16 is probably. module and 105 is the reference voltage, right? I am adding photos, and can anyone tell which bridge on the avr board should nap. while. and for which nap. comparative? because when I called the Kraft Dele service, some technician from them said that it can be different in Chinese, they could even change the order of the wires in the cube, and the cubes cannot be inserted the other way around. I am asking for help, thank you in advance, best regards.

I will add that in both modules the yellow wires go to the bridge from the S2M diodes (1000V / 3A) and the green (blue) to the M7 diodes (1000V / 1A), the question which should be 105V and 16V, is the module on because of the voltage are replaced or for another reason, but when the generator was new it worked, and now it works without avr only on the power supply ...