FAQ

TL;DR: For 2‑column car lifts on concrete B25, tie both bases with a 40×40 cm reinforced beam and use ~M18 anchors; “Concrete must have reinforcement.” [Elektroda, Strumien swiadomosci swia, post #16989924]

Why it matters:** This setup resists uplift and cracking, keeping the lift safe and aligned for daily use. This FAQ is for DIYers and shop owners planning holes, rebar, and anchors for a 2‑post lift.

Quick Facts

- Typical slab that has worked: 15 cm (≈6 in) thick under each column footprint. [Elektroda, gabik001, post #16989238]

- Example manufacturer spec reported: base 450×90 cm, ≥30–40 cm deep, concrete ≥B25, fixed with steel studs. [Elektroda, RedEd, post #16990001]

- Tie the two column feet with a 40×40 cm reinforced beam for stability. [Elektroda, Strumien swiadomosci swia, post #16989924]

- Anchors commonly used: approx. 18 mm diameter, properly fastened. [Elektroda, Strumien swiadomosci swia, post #16989924]

- DIY mixing big pads is heavy: nearly 2 m³ can mean about two pallets of bagged mix. [Elektroda, kortyleski, post #16991648]

What hole or base dimensions should I plan for a 2‑post lift?

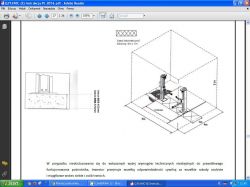

Follow your lift’s manual first. As a real‑world example, a Stenhoj 2.3F ran on a base about 450×90 cm and 30–40 cm deep in B25, fastened with steel studs. If your slab is thinner, create a reinforced pad or strip footing meeting those depths under both columns. Keep edges straight for anchor accuracy and leave curing time before loading. [Elektroda, RedEd, post #16990001]

Is one strip footing better than two separate footings?

Yes. Join the column feet with a reinforced beam to control differential movement from soil and seasonal changes. A continuous strip reduces racking when the lift cycles and when vehicles sit unevenly. Think of it like tying two gate posts together to stop them from shifting over time. [Elektroda, 266564, post #16989876]

Do I really need reinforcement in B25 concrete?

Yes. Reinforcement handles tension and prevents the base from breaking around anchors. “Concrete must have reinforcement,” especially where uplift acts during lifting. Place rebar around each foot and in any connecting beam, then respect curing time before torqueing anchors. [Elektroda, Strumien swiadomosci swia, post #16989924]

What rebar layout works around each column foot?

Use a simple cage: four longitudinal rods (e.g., 4×Ø12) tied with stirrups. Keep 40 mm concrete cover from soil and formwork. Extend bars into any 40×40 cm tie‑beam between feet so loads share. This minimal steel dramatically increases crack control and anchor pull‑out resistance. [Elektroda, 266564, post #16989814]

Can a 15 cm slab be enough under a column?

Installers report success with a 15 cm (≈6 in) slab when loads are centered and the slab is sound. That said, many lifts specify thicker bases or localized pads. Verify your manual and upgrade to a reinforced pad if your slab is thin or of uncertain quality. [Elektroda, gabik001, post #16989238]

What anchors should I choose and how tight should they be?

Use quality steel studs or ~M18 anchors compatible with your lift base plates. Drill clean, to depth, and torque to spec after the concrete reaches strength. Re‑check anchor tightness after about 1–2 weeks of use to account for settling and micro‑cracking. [Elektroda, phu_szczepan, post #17004758]

Are cast‑in studs safer than post‑installed anchors?

Cast‑in mounting pins provide excellent reliability because they engage the reinforcement and concrete mass. Some installers distrust post‑installed anchors for high uplift unless the base is well reinforced. If you can, set sleeves or studs while pouring the reinforced footing. [Elektroda, kortyleski, post #16989580]

Where can I find the exact foundation and hole sizes for my lift?

Download the DTR/manual for your specific model. Manufacturers include foundation dimensions, anchor patterns, and concrete class requirements. Use those as your controlling document, and treat forum measurements only as examples. [Elektroda, kortyleski, post #16989308]

Can I mix B25 myself in a small concrete mixer?

You can, but volume adds up fast. One user estimated nearly 2 m³ for their plan, which equals roughly two pallets of bagged mix. That is labor‑intensive and time‑sensitive for placement. Ready‑mix delivery improves consistency and finishing time. [Elektroda, kortyleski, post #16991648]

What happens if the concrete cracks around anchors?

Unreinforced pads tend to crack at the anchor line and can break apart under cyclic uplift. That creates a serious safety risk and can topple the column with a vehicle on it. Reinforcement and a tie‑beam reduce this failure mode significantly. [Elektroda, Strumien swiadomosci swia, post #16990034]

How deep should I go if I choose separate pads anyway?

If you avoid a continuous beam, increase pad size and reinforcement to resist uplift and punching. Example installs used 30–40 cm thickness under each column in B25 concrete. Tie pads with rebar if you can, even without a full beam. [Elektroda, RedEd, post #16990001]

What’s a simple 3‑step installation flow I can follow?

- Pour a reinforced 40×40 cm tie‑beam connecting both column feet in B25.

- Set studs or drill for ~M18 anchors; cure, install, and torque.

- Re‑check anchor tightness after 1–2 weeks; then load‑test per manual. [Elektroda, phu_szczepan, post #17004758]

Can I skip formwork and pour directly into soil cutouts?

Use formwork where accuracy matters. Straight, plumb edges keep anchor locations true and help achieve proper cover around rebar. Clean forms also improve finish quality and reduce voids near anchor lines, which limits crack initiation under uplift. [Elektroda, 266564, post #16989876]

What concrete class did others use successfully?

Installers referenced B25 for upgraded bases, with some older shop floors running B20. When in doubt, choose B25 as an example standard and add reinforcement for tensile loads at the anchors and tie‑beam. [Elektroda, RedEd, post #16990001]

Why do some pros dislike relying only on anchors?

Anchors see significant pull when raising vehicles. Without reinforcement or embedded pins, uplift can loosen or pry out anchors over time. Pros prefer casting pins or reinforcing so the system acts as one solid block. [Elektroda, kortyleski, post #16989580]