Hello,

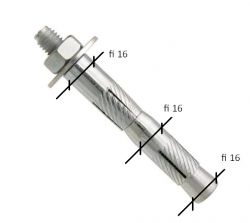

I bought anchors, unfortunately noname. Attached picture. The question is - what drill to drill in concrete for these anchors. If fi 16, this answer will not help me, because after drilling a hole with a NEW fi 16 drill, the anchor cannot be driven into this hole. It's just too tight a fit. I also immediately answer that the hole is absolutely clean, because it has been blown with compressed air. If the anchor had a name, I'd call the manufacturer.

I made the dimensions shown in the drawing with a caliper.

Regards

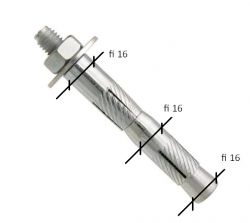

I bought anchors, unfortunately noname. Attached picture. The question is - what drill to drill in concrete for these anchors. If fi 16, this answer will not help me, because after drilling a hole with a NEW fi 16 drill, the anchor cannot be driven into this hole. It's just too tight a fit. I also immediately answer that the hole is absolutely clean, because it has been blown with compressed air. If the anchor had a name, I'd call the manufacturer.

I made the dimensions shown in the drawing with a caliper.

Regards