djszaman wrote: @Premos replacing the hall itself without reset will not do anything, data on the number of steps are saved on the motherboard, so after replacing it had to be reset.

That's why it didn't work after this general overhaul. Most likely, it was enough to just do a reset without digging and replacing anything.

Could you please send me the encoder reset procedure? I will be grateful.

Added after 2 [hours] 21 [minutes]: Hello and welcome,

Can we expand on the hall sensor?

How exactly does it determine the destinations of the brew unit?

Is a similar sensor a popular sensor mounted e.g. in the flap of the coffee machine door in Saeco / Philips to detect whether something is or is not in a certain place?

Therefore, I believe that it marks the place of "rest" of the brewer in the "lying" position.

Any deviation from the correct position would indicate a shift of the magnet itself.

Remember that we have two positions "standing" and "lying". This should distinguish when what is the fault. Whether it's "laying down" or "getting up".

These are my thoughts on it.

Regards,

Tom[/quote]

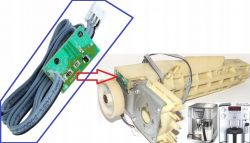

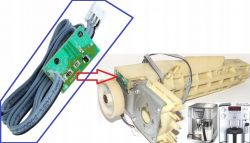

The sensor is screwed parallel to the gear pulley, in which there are four strong neodymium magnets (they demagnetized my magnetic screwdriver). A coil is clearly visible on the Hall sensor, which is excited by the magnets of the rotating pulley. I am not a service technician but an ordinary layman, but in my opinion the sensor only measures the number and speed of rotation of the pulley.

Added after 8 [minutes]:

Added after 8 [minutes]: From my experience, I think that's what he said

djshaman it was enough to do a reset and everything would work, i.e. the system would learn to push the piston a fraction of a millimeter higher to turn on the upper microswitch. The rubber band is still working