FAQ

TL;DR: For stair LEDs, use 1.5 mm² minimum on mains, 0.5–0.75 mm² on low‑voltage runs; “minimum cross‑section is 1.5mm²,” and protect ≤10 A. Feed long runs centrally, avoid daisy‑chains. [Elektroda, mawerix123, post #16997956]

Why it matters: This avoids voltage drop, overheating, and unsafe wiring in stair lighting.

Quick Facts

- Minimum mains conductor: 1.5 mm² copper; protect the circuit at ≤10 A. [Elektroda, mawerix123, post #16997956]

- LED runs: main trunk 2×0.75 mm², step drops 2×0.5 mm²; place PSU centrally. [Elektroda, mawerix123, post #16998080]

- New work must include a PE; terminate it even if unused or device is Class II. [Elektroda, kkas12, post #16998207]

- For 13–15 m total tape, avoid daisy‑chaining; home‑run each step to the PSU. [Elektroda, mmario32, post #16999938]

- Testing a big PSU with a 1 m strip is safe; nothing adverse happens. [Elektroda, mawerix123, post #17088204]

Is 2×1 mm² enough for the stair lighting circuit on the mains side?

No. The minimum cross‑section for fixed building wiring is 1.5 mm². Protect that circuit at no more than 10 A. This aligns with standard practice for stair two‑way circuits and prevents conductor overheating. “Minimum cross‑section is 1.5mm².” [Elektroda, mawerix123, post #16997956]

What cable should I run between the two stair switches?

Use a 4×1.5 mm² cable between the switches. Do not repurpose the green/yellow conductor as a live traveler. That color is reserved for PE only and misusing it is an edge‑case safety failure. [Elektroda, mawerix123, post #16997956]

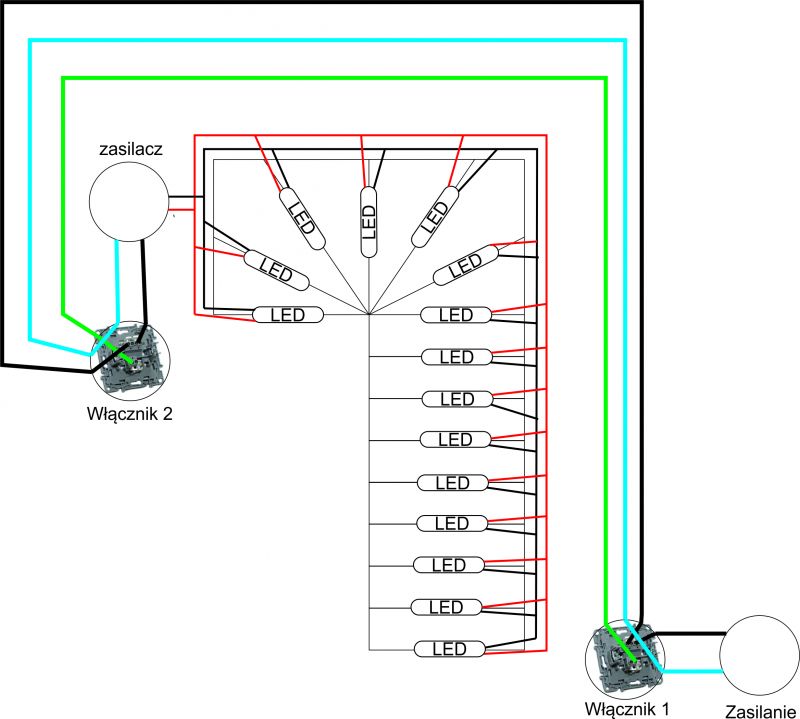

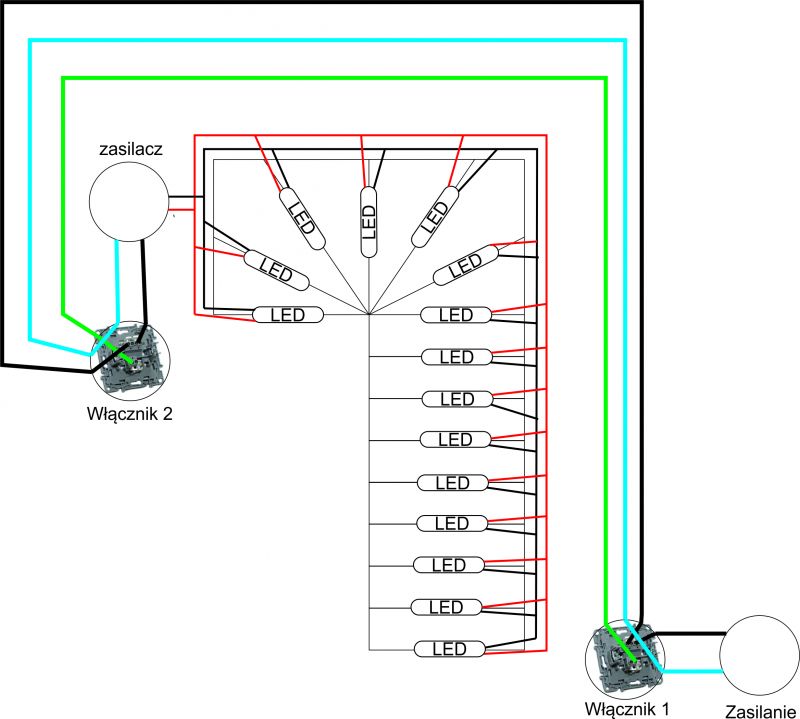

What wire sizes should I use from the power supply to the LED strips?

Run a 2×0.75 mm² trunk along the stairs, then short 2×0.5 mm² drops to each tape. Mount the power supply near the center to halve current paths and reduce voltage drop. Thicker drop wires can deform LED tape pads during soldering. [Elektroda, mawerix123, post #16998080]

Do I need a protective earth (PE) for LED stair lighting?

Yes for new work. Separate PE from neutral and route PE with the circuit, even for Class II gear. If unused, terminate it in a clamp or insulate it in the box. This prepares for future PSU changes and improves safety. [Elektroda, kkas12, post #16998207]

Where do I bond PE if my LED power supply has a metal case?

Bond the PE to the PSU’s protective earth terminal or metal housing as provided. “Each new installation MUST be [with PE], whether it will be used today or in a year.” This ensures safe replacement compatibility. [Elektroda, mawerix123, post #16998104]

Can I test a large power supply using only a 1 m LED strip?

Yes. Connecting a short 1 m strip to a higher‑rated PSU is fine for function checks. The strip draws only what it needs; nothing adverse happens during brief tests. [Elektroda, mawerix123, post #17088204]

How do I avoid voltage drop on about 13–15 m of LED tape?

Use short 2×0.5 mm² drops, a 2×0.75 mm² trunk, and place the PSU centrally. Avoid feeding the entire length through a single thin lead; that causes noticeable dimming. 13 m is a lot, so keep runs short. [Elektroda, mawerix123, post #16998206]

Should I daisy‑chain from strip to strip, or home‑run each step?

Home‑run each step back to a junction near the PSU. This simplifies installation, eases soldering, and allows adding a stair controller later. Daisy‑chains force multiple solder joints on tape and complicate service. [Elektroda, mmario32, post #16999938]

Where is the best place to mount the LED power supply for stairs?

Mount it near the center of the staircase run. A central location shortens wire lengths to both ends, balancing current and reducing drop. It also reduces visible brightness gradients between steps. [Elektroda, mawerix123, post #16998080]

Can I use a motion sensor instead of two‑way stair switches?

Yes. The control method can change without altering the basic lighting circuit concept. The switching logic for stairs is analogous whether you switch a bulb or a PSU feeding LEDs. [Elektroda, DiZMar, post #16998008]

What fuse or breaker rating should I use for a 1.5 mm² lighting circuit?

Do not exceed 10 A protection on 1.5 mm² conductors for this application. This supports safe fault clearing without overstressing the cable in walls and boxes. [Elektroda, mawerix123, post #16997956]

Is it okay to use thicker wire directly on LED tapes?

Avoid thick, stiff wire on the tape pads. Use 2×0.5 mm² flexible leads to prevent pad lift or tape deformation during soldering and mounting in aluminum profiles. [Elektroda, mawerix123, post #16998080]

How should I wire a new stair LED circuit if my existing installation is old two‑wire?

Route the new circuit with a dedicated PE and keep PE and N separate. Terminate PE in boxes even if the current device is Class II. Do not co‑opt old conductors as earth. [Elektroda, kkas12, post #16998207]

How many steps and tape length can this approach handle?

It scales to about 15 steps and roughly 13 m total tape when you centralize the PSU and home‑run drops. For longer or higher‑power tapes, consider multiple feeds. [Elektroda, piotr2593, post #16997937]

What is a stair controller and why consider one?

A stair controller sequences step lighting and enables effects. If you home‑run each step to the PSU area, adding one later is straightforward. Many off‑the‑shelf options exist. [Elektroda, mmario32, post #16999938]

Quick 3‑step: How do I home‑run each step for clean installs?

- Pull a 2×0.75 mm² trunk along the stair stringer near center.

- From each step, solder a 2×0.5 mm² drop to the tape and route to the PSU junction.

- Land all drops at the PSU/controller, then test and tidy slack. [Elektroda, mmario32, post #16999938]