This is the driver being used. Now it really works badly. When throwing reverse R, the little engine with the box will not break out of the shed.

I was doing the entire adaptation today. So in DB I chose the option (oil change in the box). The oil consumption counter was reset and "pressure science" was done according to the computer.

Then driving according to the procedure:

- we delete old adaptations with any available interface (maybe even Carsoft). You can find some on the net

descriptions of deleting adaptations such as "turn the key, press the gas" but these are fairy tales. Theoretically, adaptations should happen

delete after a very long power cut, but this is an uncertain method, and how to ensure the condition in such a system

hot box ...?

- we immediately start the adaptation process (driving even a few meters after canceling can disrupt our entire work)

- lock the box on 1, move very slowly and gently press the gas until the above-mentioned revolutions are reached

(or even a bit lower), let go of the gas and let the revs drop to about 1000-1200 (so that at higher gears the gear does not change to a lower one), then repeat the same thing 4 times

- the last time after reaching the limit speed, manually switch the gearbox to 2 and repeat the procedure 4 times

as for 1

- we do the same for each subsequent run

- after completing the procedure for 5, gently stop and let the engine work 10 minutes on P.

When finished, we turn off the engine, fire it up and check that the quality of the shifting has improved. If not, the procedure

repeat by reducing the maximum range described above by 100-200 turns.

Unfortunately, no effect. He changes gears from D1-D6 quite well, but he still does not fasten the Lock-up to D. I watched him even in the DB and saw when he fastened and when he did not. In manual mode you can say it works as it should. From 2-6 he fastens and keeps turning, you can brake the engine. There is still a strong hit on the R, and it's only happening on the warm one.

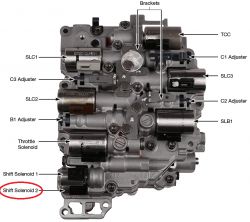

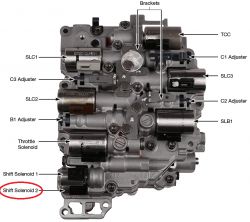

The other rudder. I think I also have a damaged ...

On One, it pulls 2/3 and does not lock the Lock-up

On the second (the one now installed) Wali when switching to R or dropping R on warm and does not lock the Lock-up

Which valve is responsible for the Lock-up and which is responsible for reverse gear?