Hi, today I wanted to present you my construction of a 3D printer from start to finish designed and made by me! I'll start with the construction, at the end I'll summarise the costs  I got interested in 3D printing through the 3D printing circle in my department at university, as I had just finished high school it would be worthwhile to get involved in something like this, but instead of participating in the life of the circle I was more interested in the machines themselves, which is why I decided to build one myself (to this day I am not in this circle, and all the knowledge about 3D printing I owe to the Internet and experience)

I got interested in 3D printing through the 3D printing circle in my department at university, as I had just finished high school it would be worthwhile to get involved in something like this, but instead of participating in the life of the circle I was more interested in the machines themselves, which is why I decided to build one myself (to this day I am not in this circle, and all the knowledge about 3D printing I owe to the Internet and experience)

I started by understanding how such a printer works and it's quite simple, there are three axes controlled by XYZ stepper motors and a head which heats up and through it the filament is "pushed" for printing. If anyone wants more information the internet is a huge source.

My printer is of the FDM type i.e. three axes in a Cartesian system. The frame is made of 20x20x2mm aluminium profiles (about 5-6m) and quite a few allen head screws (M3 and M4 of various lengths). The dimensions are about 50x50x50cm, the working area is about 30cm in the x and y axes and 40 in the Z axis.

I started by building the base of the printer, which is simply the bottom frame:

and assembling the roller guides to the printer table (Y axis).

The first problem arose when I tried to make the so-called gate, well I didn't know how to connect quite stably to the previously built frame. I initially wanted to buy ready-made connectors, but they were not available anywhere in the shape I wanted, and it was a waste of money to mill them in aluminium. I took a bit of a risk and cut the connectors out of wood using a laser.

This is what the connectors and my printer looked like. The next step was to mount the table on bearings (Y axis).

So now that I have the Y axis base I need to get on with the X and Z axes, the next step was to assemble the guides for the Z axes, I made the roller holders from an 8mm thick and 20mm wide piece of aluminium suitably drilled and threaded by me.

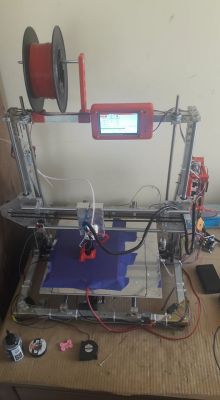

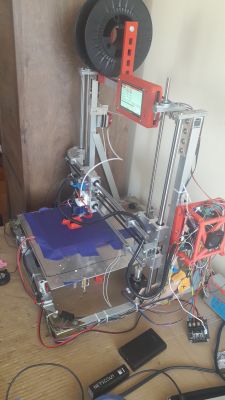

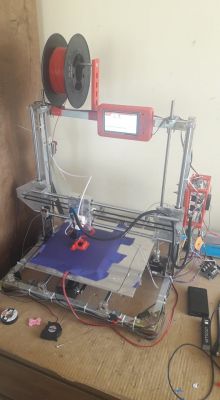

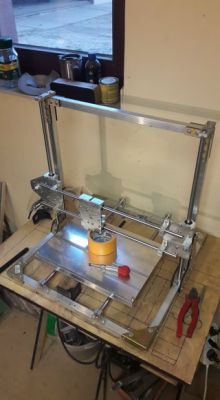

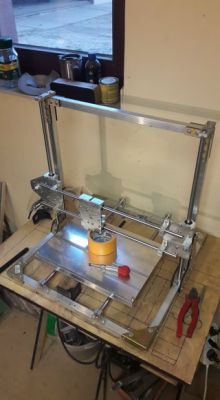

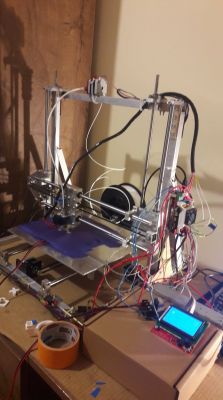

Unfortunately I stopped taking photos during this stage of the build and only have further photos once I have all the axles fitted, and it looks like this:

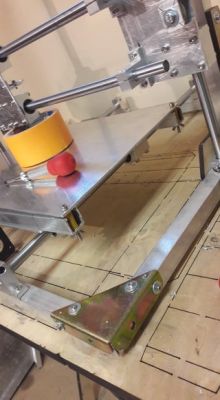

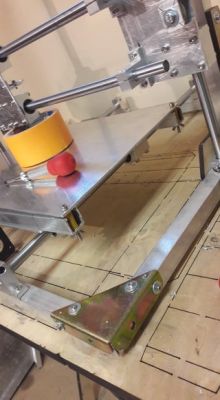

At this point the table was already mounted on springs so that it will be possible to adjust its height and level, and it looks like this:

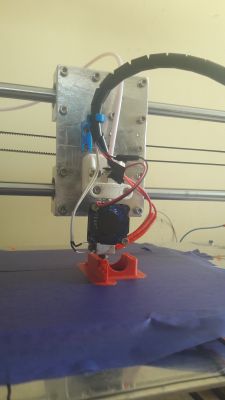

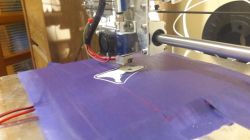

The assembly of the head remains and the toy is practically finished. I probably didn't mention, but the Y and X axes are driven by GT2 6mm belts and the Z axis by two trapezoidal screws with T8 threads (the X and Y axes have one motor each, while the Z axis has two motors). After assembling the head, the first prints took place.

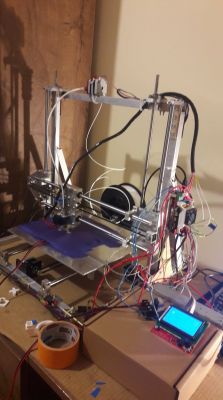

Here a picture from a week ago, since then I have added a heated table and arranged the cables (a little). Now the printer is almost finished and ready to play with.

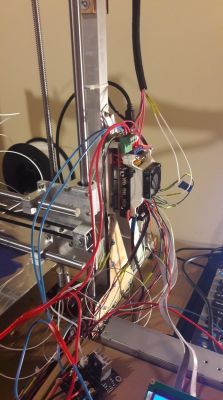

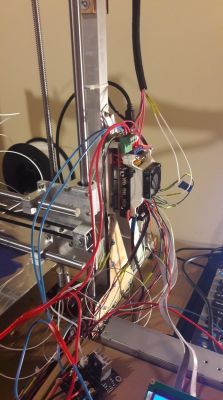

As far as the electronics are concerned, I used a fairly common solution which is an arduino mega2560 (clone) with a ramps 1.4 overlay (+stepsticks A4988 for the stepper motors). The stepper motors are the well-known nema 17 (no point in packing bigger ones). The addition here is an LCD controller that allows the printer to work without a computer.

Forgive me for such a short description, it's quite late, I will answer any questions tomorrow

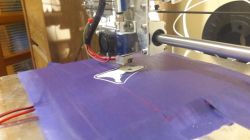

Example prints:

I must sadly add that unfortunately still not every print comes out nicely, I blame this on the Chinese head and I am trying to buy an original e3d head

The cost of such a play:

- 20x20x2m aluminium profiles and 3mm sheet - 100zl

- Screws, nuts, washers - 100zl (a lot left over)

- Slides (12mm shafts) 6pcs - 75zl

- Bearings 12pcs - 100zl

- Holders for slides 8pcs - 40zl

- Bearings for trapezoidal screws 2pcs - 10zl

- Trapezoidal screws T8 500mm with cap 2szt - 30zl

- Flexible couplings 2pcs - 20zl

- Motor mounts 3pcs - 20zl

- GT2 6mm belt for 5m - 8zł

- Gears for the belt (several different ones) - 20zl

- Nema 17 motors 5pcs - 140zl

- Arduino mega2560 clone - 40zl

- Ramps 1.4 - 15zl

- Stepsticks A4988 4pcs - 10zł

- LCD - 40zl

- MK8 extruder - 20zl (filament feeder)

- E3D clone head - 20zl

- Limit switches - 10zl

Total - 818zł

Things such as cables and other fuckers I skip because I had at home,

i do not remember more, if something is please ask

The costs were certainly a little higher but that was because sometimes the wrong thing was sent or something just broke.

If anyone wants to ask if it's worth it, it's honestly rather not. It's rare for a person to print anything bigger than 20x20x20cm and for the amount I spent you can get a decent printer for hobby printing. On the other hand, if someone wants to try their hand at it and have great satisfaction then I recommend it, super fun.

If someone decides to build a 3D printer I will be happy to help start this adventure, so feel free to write.

Greetings and good night

I started by understanding how such a printer works and it's quite simple, there are three axes controlled by XYZ stepper motors and a head which heats up and through it the filament is "pushed" for printing. If anyone wants more information the internet is a huge source.

My printer is of the FDM type i.e. three axes in a Cartesian system. The frame is made of 20x20x2mm aluminium profiles (about 5-6m) and quite a few allen head screws (M3 and M4 of various lengths). The dimensions are about 50x50x50cm, the working area is about 30cm in the x and y axes and 40 in the Z axis.

I started by building the base of the printer, which is simply the bottom frame:

and assembling the roller guides to the printer table (Y axis).

The first problem arose when I tried to make the so-called gate, well I didn't know how to connect quite stably to the previously built frame. I initially wanted to buy ready-made connectors, but they were not available anywhere in the shape I wanted, and it was a waste of money to mill them in aluminium. I took a bit of a risk and cut the connectors out of wood using a laser.

This is what the connectors and my printer looked like. The next step was to mount the table on bearings (Y axis).

So now that I have the Y axis base I need to get on with the X and Z axes, the next step was to assemble the guides for the Z axes, I made the roller holders from an 8mm thick and 20mm wide piece of aluminium suitably drilled and threaded by me.

Unfortunately I stopped taking photos during this stage of the build and only have further photos once I have all the axles fitted, and it looks like this:

At this point the table was already mounted on springs so that it will be possible to adjust its height and level, and it looks like this:

The assembly of the head remains and the toy is practically finished. I probably didn't mention, but the Y and X axes are driven by GT2 6mm belts and the Z axis by two trapezoidal screws with T8 threads (the X and Y axes have one motor each, while the Z axis has two motors). After assembling the head, the first prints took place.

Here a picture from a week ago, since then I have added a heated table and arranged the cables (a little). Now the printer is almost finished and ready to play with.

As far as the electronics are concerned, I used a fairly common solution which is an arduino mega2560 (clone) with a ramps 1.4 overlay (+stepsticks A4988 for the stepper motors). The stepper motors are the well-known nema 17 (no point in packing bigger ones). The addition here is an LCD controller that allows the printer to work without a computer.

Forgive me for such a short description, it's quite late, I will answer any questions tomorrow

Example prints:

I must sadly add that unfortunately still not every print comes out nicely, I blame this on the Chinese head and I am trying to buy an original e3d head

The cost of such a play:

- 20x20x2m aluminium profiles and 3mm sheet - 100zl

- Screws, nuts, washers - 100zl (a lot left over)

- Slides (12mm shafts) 6pcs - 75zl

- Bearings 12pcs - 100zl

- Holders for slides 8pcs - 40zl

- Bearings for trapezoidal screws 2pcs - 10zl

- Trapezoidal screws T8 500mm with cap 2szt - 30zl

- Flexible couplings 2pcs - 20zl

- Motor mounts 3pcs - 20zl

- GT2 6mm belt for 5m - 8zł

- Gears for the belt (several different ones) - 20zl

- Nema 17 motors 5pcs - 140zl

- Arduino mega2560 clone - 40zl

- Ramps 1.4 - 15zl

- Stepsticks A4988 4pcs - 10zł

- LCD - 40zl

- MK8 extruder - 20zl (filament feeder)

- E3D clone head - 20zl

- Limit switches - 10zl

Total - 818zł

Things such as cables and other fuckers I skip because I had at home,

i do not remember more, if something is please ask

The costs were certainly a little higher but that was because sometimes the wrong thing was sent or something just broke.

If anyone wants to ask if it's worth it, it's honestly rather not. It's rare for a person to print anything bigger than 20x20x20cm and for the amount I spent you can get a decent printer for hobby printing. On the other hand, if someone wants to try their hand at it and have great satisfaction then I recommend it, super fun.

If someone decides to build a 3D printer I will be happy to help start this adventure, so feel free to write.

Greetings and good night

Cool? Ranking DIY