DIY Kiosk - or electronics magazine

During the construction phase...

Hello esteemed forumers.

The year 2025 is upon us and as is customary, it's good to have some New Year's resolutions.

I decided that I would start the new year by putting my studio, and workshop, in order.

What was my surprise when I opened the book calendar for 2025, where the first entry was the New Year's resolution: "Clean up the studio".

So I opened the 2024 calendar and to my eyes appeared a similar entry.

I decided to act and cleaned up the workshop first.

On reaching the workshop, however, I realised that the main cause of the mess was the lack of organisation in the small electronics.

Over the last few years I have been buying bins and organisers, stuffing what I need in there and trying to find a place for it all.

There have been many ideas, but so far I haven't fully implemented any of them because there has always been an "BUT".

I thought that since 2025 brought us the development of AI, I would be able to find a solution to the problem using it.

This is what happened. The best suggestion of many turned out to be to use a wall and build a shelving unit on top of it with small shelves for all the lockable containers in which I have most of the small things I often can't find.

However, further questions constantly arose as to how to group it all together and whether it couldn't somehow be linked to my database for electronic component parts I have on disk (File folders).

While browsing YouTube I came across an interesting project with a Raspberry PI and voice assistant combined with WS2812B LEDs.

I thought it wasn't worth copying someone else's ideas and it was worth catching up on two years' worth of work.

I set to work.

Project assumptions:

-Cheap to build

-Simple to use

Over the last few years I have weaned myself on microchip programming and 3D printing with React,which has proved to be a saviour.

So I decided to combine a PC-based catalogue database with lights on the shelf.

As a first step, I needed to catch up on my PC program development.

So I proceeded to create a program in the React Vite environment in combination with Electron for Windows directory support, and for a breath of fresh air use Tailwind.

Much of the syntax has unfortunately changed a lot, but with the help of AI I thought I'd get some training.

With two weeks of time over the Christmas period, I decided to split the project into three factions:

1. PC database (Executable .EXE file)

2. Program on ESP (I settled on ESP8266 version of Wemos D1 mini + OLED SSD1306 128x32 - I have some on hand)

3. Bookcase (Using 3D printing)

I started the design...

Both the studio (computer with 2 screens) and the workshop (computer with 2 touchscreens) had to get their storage environments. The difference being that in one system the electronics and in the other more mechanics and spare parts.

One PC runs on a 64 bit system, the other on an x86 system - it has to work on both.

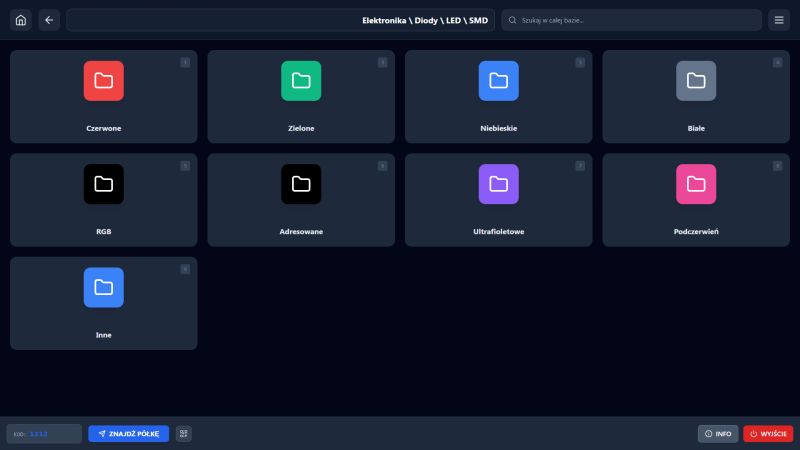

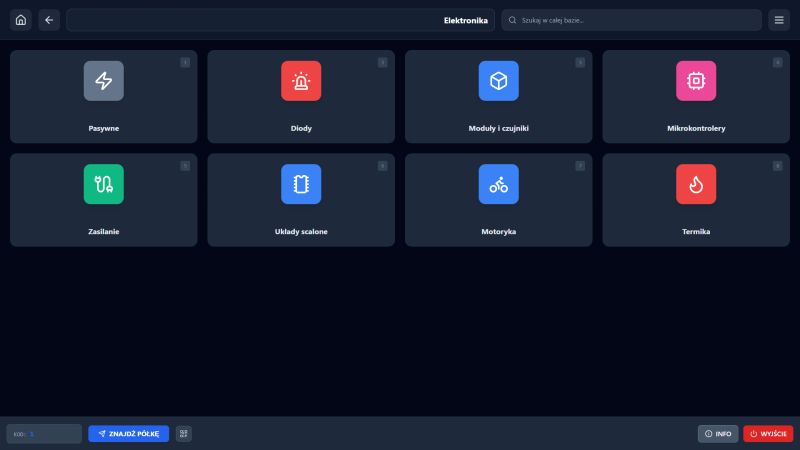

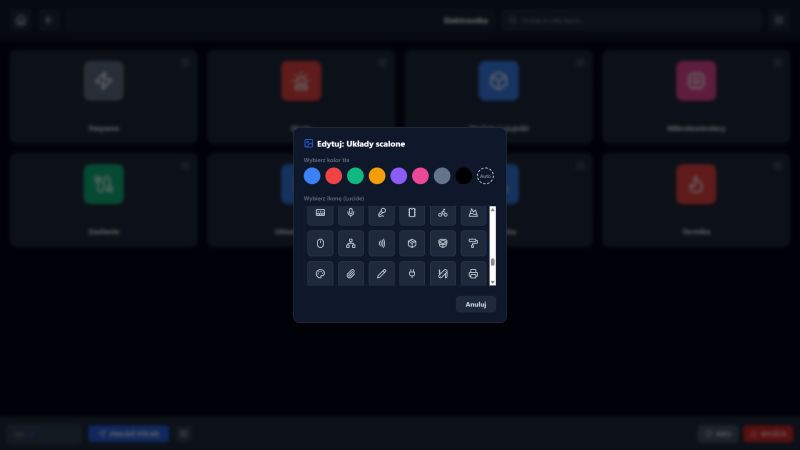

At the outset, I set out to make the interface clear and fun to use, whether from a mouse, keyboard, touchscreen or code scanner (parsing required).

The layout had to be simple:

-Top bar (home location, back, access path field, search field, application MENU)

-Bottom bar (Location code display field, button to send code to ESP8266, QR code frame, "info" field, and exit)

-MENU (Database path indication field, port selection field for communication with ESP, option to change theme to dark)

-MAIN SCREEN (folders with prefix as tile, and files opened with default Windows applications {.pdf, .png...}

In order to keep everything consistent and not spread out, I decided that the directories will be numbered with a prefix (1_Electronics, 2_Chemistry...).

In the program, however, we will show the name of the catalogue without the prefix, with the difference that the prefix will be used to navigate using the keyboard, or the attached code scanner on the boxes (in case you don't know where to put the code box)

Each directory with a prefix can contain other directories inside with a prefix as well (the so-called children of the parent directory)

An example of part of my directory structure:

As you can see, each successive directory is tabbed.

Generating such a structure is not at all complicated and can be done, for example, with a graphical program for Android (SimpleMind) and saved to a text file. The creation of all directories, on the other hand, is done by pasting the given structure into a created .ps1 executable file run from a terminal.

There is no great philosophy here, and after a few days of playing around and bug-fixing, the program was run in a version that finally satisfied me.

In the meantime, I have made a few dozen compilations for the ESP8266 with better or worse results.

I was keen that, since the string of 200 WS2812B LEDs that served me last year as Christmas tree lights in the backyard under ESP8266 control and WLED batch on a 1 Ampere power supply, they should work on the computer's USB port alone, without external power.

This in turn means that we do not have to contend with operation over wifi, but operate the ESP via the serial port.

ESP configuration will be done via the WEB side of the device.

So I added Little FS, set the required memory parameters and....

Well it works, but during testing I found that when forcing the device from the WEB page, the device can crash (on the browser side - the rest was OK). I was a bit nostalgic for the ESP32, where I would simply split the LED display animation and WEB and Serial page handling into two processes.

So I changed the OLED and WS2812B refresh to 30x per second and some other blocking options.

I removed the blocking Serial.readStringUntil() function and replaced it with a SerialBuffer, which collects characters in the background without stopping the CPU. Smart rendering and a few other small modifications were applied and so here we are on 4 January 2026 and the final version.

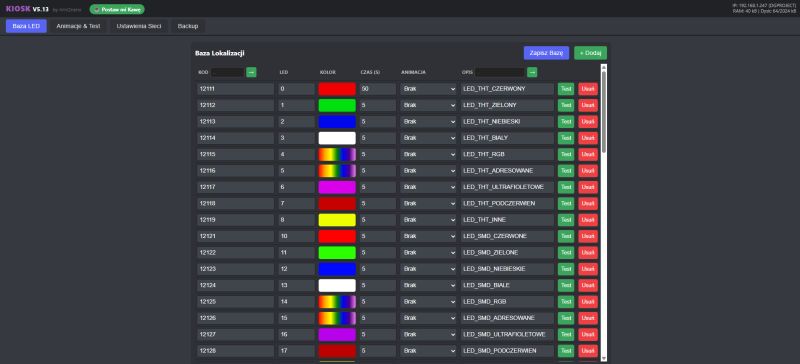

What remains are the shelves and assigning the appropriate colours, and animations.

In ESP, I used the option to display a location defined by a colour with a choice of one of three available animations in the form of a following light to the target (from one end, the other, or both at the same time) - the METEOR Effect.

When we return in the application to the parent directory (parent) illuminates all the items inside the catalogue in the defined colours, with the difference that we can define in the menu the effect of illuminating multiple fields simultaneously and specify the lighting time and power.

To make it easier to save the database, and to show e.g. LED RGB, I have also added a shimmering rainbow colour pixel assigned to absolute black in the colour palette (colour:000000)

The database is saved in a readable way, giving the possibility to be more ambitious, edit even from an EXCEL data sheet.

Example of database syntax:

{

"code": "12111",

"led": 1,

"r": 240,

"g": 0,

"b": 0,

"time": 5000,

"anim": 2,

"desc": "LED_THT_RED"

},

{

"code": "12112",

"led": 2,

"r": 0,

"g": 224,

"b": 15,

"time": 5000,

"anim": 2,

"desc": "LED_THT_GREEN"

},

There is no great philosophy here, and after a few days of playing around and bug-fixing, the program was run in a version that finally satisfied me.

In the meantime, I made a few dozen compilations for the ESP8266 with better or worse results.

I was keen that, since the string of 200 WS2812B LEDs that served me last year as Christmas tree lights in the backyard under ESP8266 control and a WLED batch on a 1 Ampere power supply would work on the computer's USB port alone, without external power.

This in turn means that we do not have to contend with operation over wifi, but operate the ESP via the serial port.

ESP configuration will be done via the WEB side of the device.

So I added Little FS, set the required memory parameters and....

Well it works, but during testing I found that when forcing the device from the WEB page, the device can crash (on the browser side - the rest was OK). I was a bit nostalgic for the ESP32, where I would simply separate the LED display animation and WEB and Serial page handling into two processes.

So I changed the OLED and WS2812B refresh to 30x per second and some other blocking options.

I removed the blocking Serial.readStringUntil() function and replaced it with a SerialBuffer, which collects characters in the background without stopping the CPU. Smart rendering and a few other small modifications were applied and so here we are on 4 January 2026 and the final version.

What remains are the shelves and assigning the appropriate colours, and animations.

In ESP, I used the option of displaying a location defined by a colour with the possibility of choosing one of the three available animations in the form of a following light to the target (from one end, the other, or both at the same time) - the METEOR effect.

When we return in the application to the parent catalogue, all the items inside the catalogue light up in the defined colours, with the difference that we can define in the menu the effect of lighting up many fields simultaneously and specify the lighting time and power.

To make it easier to save the database, and to show e.g. LED RGB, I have also added a shimmering rainbow colour pixel assigned to absolute black in the colour palette (colour:000000)

The database is saved in a readable way, giving the possibility to be more ambitious, edit even from an EXCEL data sheet.

Example of database syntax:

The shelf lighting controller itself is nothing more than a WEMOS D1 MINI + OLED + (WS2812B LED string 10cm raster - 200pix)

// Of course with a resistor depending on the length of the wire to the LED and a 1000uF capacitor.

I hope the project will arouse interest.

With that, I wish you all the best for the new year 2026.

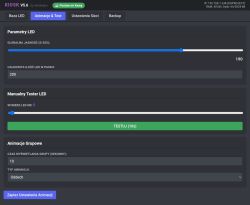

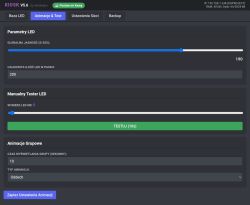

Programme operation on PC

WEB page operation on ESP8266

Google drive downloads:

https://drive.google.com/drive/folders/1hnoxh2GpS30uNQiNsFQavRU_DW0FagfV?usp=sharing

During the construction phase...

Hello esteemed forumers.

The year 2025 is upon us and as is customary, it's good to have some New Year's resolutions.

I decided that I would start the new year by putting my studio, and workshop, in order.

What was my surprise when I opened the book calendar for 2025, where the first entry was the New Year's resolution: "Clean up the studio".

So I opened the 2024 calendar and to my eyes appeared a similar entry.

I decided to act and cleaned up the workshop first.

On reaching the workshop, however, I realised that the main cause of the mess was the lack of organisation in the small electronics.

Over the last few years I have been buying bins and organisers, stuffing what I need in there and trying to find a place for it all.

There have been many ideas, but so far I haven't fully implemented any of them because there has always been an "BUT".

I thought that since 2025 brought us the development of AI, I would be able to find a solution to the problem using it.

This is what happened. The best suggestion of many turned out to be to use a wall and build a shelving unit on top of it with small shelves for all the lockable containers in which I have most of the small things I often can't find.

However, further questions constantly arose as to how to group it all together and whether it couldn't somehow be linked to my database for electronic component parts I have on disk (File folders).

While browsing YouTube I came across an interesting project with a Raspberry PI and voice assistant combined with WS2812B LEDs.

I thought it wasn't worth copying someone else's ideas and it was worth catching up on two years' worth of work.

I set to work.

Project assumptions:

-Cheap to build

-Simple to use

Over the last few years I have weaned myself on microchip programming and 3D printing with React,which has proved to be a saviour.

So I decided to combine a PC-based catalogue database with lights on the shelf.

As a first step, I needed to catch up on my PC program development.

So I proceeded to create a program in the React Vite environment in combination with Electron for Windows directory support, and for a breath of fresh air use Tailwind.

Much of the syntax has unfortunately changed a lot, but with the help of AI I thought I'd get some training.

With two weeks of time over the Christmas period, I decided to split the project into three factions:

1. PC database (Executable .EXE file)

2. Program on ESP (I settled on ESP8266 version of Wemos D1 mini + OLED SSD1306 128x32 - I have some on hand)

3. Bookcase (Using 3D printing)

I started the design...

Both the studio (computer with 2 screens) and the workshop (computer with 2 touchscreens) had to get their storage environments. The difference being that in one system the electronics and in the other more mechanics and spare parts.

One PC runs on a 64 bit system, the other on an x86 system - it has to work on both.

At the outset, I set out to make the interface clear and fun to use, whether from a mouse, keyboard, touchscreen or code scanner (parsing required).

The layout had to be simple:

-Top bar (home location, back, access path field, search field, application MENU)

-Bottom bar (Location code display field, button to send code to ESP8266, QR code frame, "info" field, and exit)

-MENU (Database path indication field, port selection field for communication with ESP, option to change theme to dark)

-MAIN SCREEN (folders with prefix as tile, and files opened with default Windows applications {.pdf, .png...}

In order to keep everything consistent and not spread out, I decided that the directories will be numbered with a prefix (1_Electronics, 2_Chemistry...).

In the program, however, we will show the name of the catalogue without the prefix, with the difference that the prefix will be used to navigate using the keyboard, or the attached code scanner on the boxes (in case you don't know where to put the code box)

Each directory with a prefix can contain other directories inside with a prefix as well (the so-called children of the parent directory)

An example of part of my directory structure:

Code: C / C++

As you can see, each successive directory is tabbed.

Generating such a structure is not at all complicated and can be done, for example, with a graphical program for Android (SimpleMind) and saved to a text file. The creation of all directories, on the other hand, is done by pasting the given structure into a created .ps1 executable file run from a terminal.

Code: Powershell

There is no great philosophy here, and after a few days of playing around and bug-fixing, the program was run in a version that finally satisfied me.

In the meantime, I have made a few dozen compilations for the ESP8266 with better or worse results.

I was keen that, since the string of 200 WS2812B LEDs that served me last year as Christmas tree lights in the backyard under ESP8266 control and WLED batch on a 1 Ampere power supply, they should work on the computer's USB port alone, without external power.

This in turn means that we do not have to contend with operation over wifi, but operate the ESP via the serial port.

ESP configuration will be done via the WEB side of the device.

So I added Little FS, set the required memory parameters and....

Well it works, but during testing I found that when forcing the device from the WEB page, the device can crash (on the browser side - the rest was OK). I was a bit nostalgic for the ESP32, where I would simply split the LED display animation and WEB and Serial page handling into two processes.

So I changed the OLED and WS2812B refresh to 30x per second and some other blocking options.

I removed the blocking Serial.readStringUntil() function and replaced it with a SerialBuffer, which collects characters in the background without stopping the CPU. Smart rendering and a few other small modifications were applied and so here we are on 4 January 2026 and the final version.

What remains are the shelves and assigning the appropriate colours, and animations.

In ESP, I used the option to display a location defined by a colour with a choice of one of three available animations in the form of a following light to the target (from one end, the other, or both at the same time) - the METEOR Effect.

When we return in the application to the parent directory (parent) illuminates all the items inside the catalogue in the defined colours, with the difference that we can define in the menu the effect of illuminating multiple fields simultaneously and specify the lighting time and power.

To make it easier to save the database, and to show e.g. LED RGB, I have also added a shimmering rainbow colour pixel assigned to absolute black in the colour palette (colour:000000)

The database is saved in a readable way, giving the possibility to be more ambitious, edit even from an EXCEL data sheet.

Example of database syntax:

{

"code": "12111",

"led": 1,

"r": 240,

"g": 0,

"b": 0,

"time": 5000,

"anim": 2,

"desc": "LED_THT_RED"

},

{

"code": "12112",

"led": 2,

"r": 0,

"g": 224,

"b": 15,

"time": 5000,

"anim": 2,

"desc": "LED_THT_GREEN"

},

There is no great philosophy here, and after a few days of playing around and bug-fixing, the program was run in a version that finally satisfied me.

In the meantime, I made a few dozen compilations for the ESP8266 with better or worse results.

I was keen that, since the string of 200 WS2812B LEDs that served me last year as Christmas tree lights in the backyard under ESP8266 control and a WLED batch on a 1 Ampere power supply would work on the computer's USB port alone, without external power.

This in turn means that we do not have to contend with operation over wifi, but operate the ESP via the serial port.

ESP configuration will be done via the WEB side of the device.

So I added Little FS, set the required memory parameters and....

Well it works, but during testing I found that when forcing the device from the WEB page, the device can crash (on the browser side - the rest was OK). I was a bit nostalgic for the ESP32, where I would simply separate the LED display animation and WEB and Serial page handling into two processes.

So I changed the OLED and WS2812B refresh to 30x per second and some other blocking options.

I removed the blocking Serial.readStringUntil() function and replaced it with a SerialBuffer, which collects characters in the background without stopping the CPU. Smart rendering and a few other small modifications were applied and so here we are on 4 January 2026 and the final version.

What remains are the shelves and assigning the appropriate colours, and animations.

In ESP, I used the option of displaying a location defined by a colour with the possibility of choosing one of the three available animations in the form of a following light to the target (from one end, the other, or both at the same time) - the METEOR effect.

When we return in the application to the parent catalogue, all the items inside the catalogue light up in the defined colours, with the difference that we can define in the menu the effect of lighting up many fields simultaneously and specify the lighting time and power.

To make it easier to save the database, and to show e.g. LED RGB, I have also added a shimmering rainbow colour pixel assigned to absolute black in the colour palette (colour:000000)

The database is saved in a readable way, giving the possibility to be more ambitious, edit even from an EXCEL data sheet.

Example of database syntax:

Code: C / C++

The shelf lighting controller itself is nothing more than a WEMOS D1 MINI + OLED + (WS2812B LED string 10cm raster - 200pix)

// Of course with a resistor depending on the length of the wire to the LED and a 1000uF capacitor.

I hope the project will arouse interest.

With that, I wish you all the best for the new year 2026.

Programme operation on PC

WEB page operation on ESP8266

Google drive downloads:

https://drive.google.com/drive/folders/1hnoxh2GpS30uNQiNsFQavRU_DW0FagfV?usp=sharing

Cool? Ranking DIY