I have made myself a transformer rectifier to charge the car battery, with automatic charge control - on/off principle - so that charging can be left unattended for a long time. The circuit has two basic tasks:

- enable charging when the battery is connected

- switch off charging when the battery is charged or in an error situation

The garage aesthetics of the unit are provided by the casing after the ATX power supply.

However, I took care to at least divide the front and rear panels.

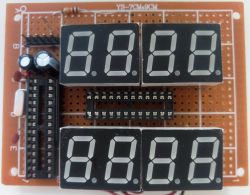

The side that was visible from the back of the computer is now the front panel. There is a red seven-segment LED display (2 rows of 4 digits with decimal points), a big red main switch and 4 momentary buttons - 2 blue on the left (closer to the display) and 2 red on the right.

There is a fuse socket on the back, a positive and negative terminal, and a power cable sticking out.

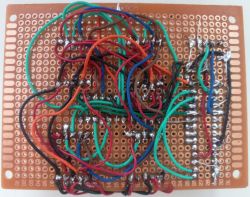

Internal construction

The transformer is from a very old TV-SAT receiver, has about 40 W and has 3 secondary windings with the following AC voltages (at ~240 V on the primary):

| Wire colour | Voltage | Application | |

| brown | 7,95 V | Control electronics supply | |

| yellow | 15,39 V | the convolution referred to below first | |

| blue | 22 V | the convolution called below the second |

The electronics are powered by a separate small rectifier bridge and 7805 .

One of the other two windings is connected via relays to this second (larger) bridge, from which the rectified voltage exits via a shunt to the banana sockets on the rear.

Both bridges and 7805 are mounted on a heatsink.

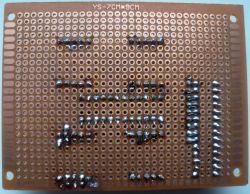

The main board is a 7x9 cm universal board. It already receives stabilised 5 volts.

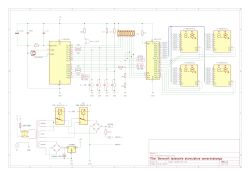

There is a socket for Atmel on the board AT89C2051 and EEPROM AT24C02 , but I replaced them with a clone: Nuvoton W79E2051 . Compared to the original, it has built-in non-volatile memory , watchdog a and brown-out reset , well it is 2x faster in this application.

Also: 4 double-digit displays D-5625ASK11 , which light up quite nicely, operated by MAX7219 ; and a squeaker.

The following peripheral modules from Aliexpress are connected to the board:

- 2 5 V SRD-05VDC-SL-C relay module with optoisolation HL-525 - one closes the circuit and the other switches the windings

- via I²C: module INA226 for voltage and current measurement, with wire soldered in parallel to a 0.1 Ω shunt

- via UART: bluetooth module SPP JDY-33 - together with the rest enclosed in a metal box and maybe because of that it has a range similar to the display through the window

In the module INA226 I short-circuit the VBS with IN-, i.e. the voltage is measured between the plus and minus terminals, without a shunt.

The module has a built-in 0.1 Ω shunt to measure currents up to 0.8 A. To extend this range, I soldered a piece of wire in parallel. I don't know what resistance it has, but after calibrating with an H4 bulb (current about 4 A), with a calibration register value of 1345 the result in mA agrees with the meter on the 10 A range. I had previously tried with some 0.1 Ω resistors, but the range was then exceeded.

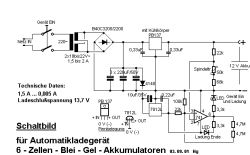

Schemat

Algorithm

INA226 operates in the fastest possible mode i.e. without any averaging, 140 µs per measurement.

The processor reads the voltage and current for 100 ms in a tight loop and does the relaxation.

At the end we have 4 values: U min , U max , I min , I max .

I am counting on is that within 10 straightened halves of a sine wave it is possible to catch the extremes even without synchronisation with the zero crossing.

W79E2051 manages to read data from INA226 400x within these 100 ms, a AT89C2051 - 200x.

Then a state machine is flown which, based on the above 4 values and the charging time, changes the state and switches the relays.

This is followed by converting the parameters to decimal numbers and sending to the display, and possibly sending data to the UART (and further via bluetooth if paired) - and the cycle of measurements repeats.

Display

The upper and lower displays one of 7 values independently selectable by the blue button next to the respective display:

| 0 | State of the automatic charge control as 2 spaces and 2 digits, or error code E-XX |

| 1 | Charge time - in minutes, with one decimal digit |

| 2 | Number of voltage and current samples read in 100 ms |

| 3 | U min - in volts, with two decimal digits |

| 4 | U max - in volts, with two decimal digits |

| 5 | I min - in amperes, with three decimal digits |

| 6 | I max - in amperes, with three decimal digits |

When the button is pressed, a single digit with the index of the newly selected parameter appears on the display. It disappears when the button is released.

If an error occurs, its code will be shown on the lower display instead of what the user wanted. Unless, of course, he has turned on the status display (index 0) on the upper display.

Buttons

The blue buttons are used to select what is to be displayed on the display next to it. (However, these changes will not be saved permanently until you enter and exit the menu.)

The lower red button switches loading on and off. It also clears the error status.

The upper red button enters the menu and then cycles through all options. The blue buttons are then used to set the value of the selected option (top=more, bottom=less). The lower red button exits the menu and saves the setting changes in non-volatile memory.

Autorepetition (30x/s) works on the blue buttons.

Menu

| Option | Scope | Default | Description | |

| bEEP | >-1 | 1 | Whether or not it beeps when the button is pressed | |

| LEd | >-15 | 8 | Display brightness as fill of multiplexing cycle from 1/32 to 31/32 in 2/32 increments.

Value entered into Intensity Register circuit MAX7219 . | |

| rCAL | 0000-9999 | 1345 | Current Current Factor - the number, by which the shunt voltage must be multiplied

(expressed in units of 2.5 µV) to give the result in milliamps when divided by 2048. Value entered into Calibration Register layout INA226 . | |

| CALI | Current factor calibration mode.

Pressing the lower or upper blue button switches INA226 into result averaging mode (so that they correspond to the universal meter) and enters a waiting state for the calibration start conditions. You have to connect e.g. a light bulb in series with the ammeter to the output connectors and correct the measurement result displayed on the lower display with the blue buttons. | |||

| T 0 | 000.0-999.9 | 960.0Upload time limit, in minutes. | ||

| I 0 | 0.000-9,999 | 0.200 | Bottom limit of peak charging current, in A.

Also the upper limit of current flowing when charging is switched off. | |

| I 1 | 0.000-9.999 | 7,000Upper limit of peak charging current, in A. | ||

| I 2 | 0.000-9.999 | 5,000 | Upper limit of peak charging current of the first winding, in A,

below which it is possible to switch to the second winding. | |

| U 0 | 00.00-99.99 | 10.00 | Bottom limit of minimum voltage required to start charging, in V. | |

| U 1 | 00.00-99.99 | 13.20Upper limit of minimum voltage required to start charging, in V. | ||

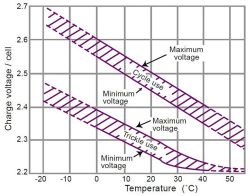

| U 3 | 00.00-99.99 | 14.60Upper limit of peak charging voltage, in V. | ||

| U 4 | 00.00-99.99 | 14.40Upper limit of minimum charging voltage, in V. | ||

| U 5 | 00.00-99.99 | 13.80 | Upper limit of peak charging voltage, in V,

below which it is possible to switch to the second winding. | |

| AuOn | >-1 | 1 | Whether, when switched on, to enter immediately into a waiting state for charging conditions (1),

or not switch on charging (0). | |

| rECH | >0-1 | 0 | Whether, after charging, to return to wait for conditions to charge (1),

or not to switch on charging again (0). | |

| bErr | 0-1 | |||

| bEnd | 0-1 | 1 | Whether to signal the end of charging by beeping. | |

| FACT | Upper blue button = return to factory settings.

Lower blue button = exit menu without saving changes. |

Automatic charge control

| State | Transmitters | Description | |

| 0 | Disabled | Uncharged. This is the state when switched on when option AuOn =0. | |

| 1 | off | 1 | Waiting for conditions to start charging (assumed - connecting the battery).

This is the state after switching on when the option AuOn =1. |

| 2 | Included first winding | Charging the battery with normal current | |

| 3 | Included second winding | Charging the battery with increased current | |

| 4 | Off | Waiting conditions to start calibration of current measurement with the second winding | |

| 5 | Excluded | Waiting for conditions to start calibration of current measurement with first winding | |

| 6 | Included X winding | Calibration, and X depends on whether we have moved from state 4 or state 5 |

Diagram of states

Error codes <br/span>

| Code | State | Destination | |

| E-01 | 1 | When the charge is turned off, a current of I min >= I 0 | |

| E-02 | 1 | When the charge is turned off, a current of I max >= I 0 | |

| E-03 | 2 | The set charging time T | has been exceeded charging time T 0 |

| E-04 | 2 | In zero sine wave current module I min does not fall below threshold I 0 | |

| E-05 | 2 | Peak current charge exceeds limit I 1 | |

| E-06 | 2 | In the zero of the sine wave, the voltage has dropped below U 0 (i.e., e.g. battery disconnected) | |

| E-07 | 3 | 3 | The preset charging time T 0 |

| E-08 | 3In zero sine wave current module I min does not fall below threshold I 0 | ||

| E-09 | 3 | In the zero of the sine wave, the voltage dropped below U 0 (i.e. e. battery disconnected) | |

| E-10 | 4,5 | When power is off, current I min >= I 0 | |

| E-11 | 4,5 | When power is off, current I max >= I 0 | |

| E.226 | Communication error with INA226 (occurs regardless of state machine) |

After the error E.226 the processor will go to sleep for those 100 ms and try to initialise INA226 again (over and over again).

Transition codes between states that are not considered an error:

| Code | Z | To | From | ||

| P-10 | 1 | 2 | Timer reset, start of charging with winding one | ||

| P-20 | 2 | 3 | Charge switching from winding one to winding two | ||

| P-15 | 3 | 2 | 3 | 2 | Transfer of charge back from winding two to winding one due to overcurrent |

| P-16 | 3 | 2 | 3 | 2 | Transfer of charge back from winding two to winding one due to voltage overshoot |

|

| P-30 | 2 | 0/1* | Finished charging due to minimum voltage exceeded | ||

| P-31 | 2 | 0/1* | Completion of charging due to peak voltage exceedance | ||

| P-32 | 2 | 0/1* | 2 | End of charge due to failure to achieve minimum peak current | |

| P-33 | 3 | 0/1* | Finished charging due to minimum voltage exceeded | ||

| P-34 | 3 | 0/1* | Failure to charge due to minimum peak current not being reached | ||

| P-50 | 4/5 | 6 | Begin calibration with winding two/first |

*) Depends on whether the option is enabled rECH : no

Bluetooth 2

The device itself sends lines of text via bluetooth with an error or pass code, such as:

P-50 0015 0191 0000 0002 FFF8 0002

P-50 0017 0192 0000 0001 FFFA 0002It is possible to send the letter v , which activates and deactivates the talk mode - that is, sending the above block of data after each measurement cycle (every 100 ms), in which case instead of an error/transition code - unless one or the other has occurred - there is only a two-digit status number, e.g.: :

00 0035 0168 0000 0002 FFF8 0003

00 0035 0167 0000 0001 FFF8 0002

P-50 0035 0156 0000 0002 FFF8 0002

06 0035 016A 0000 0000 FFFD FFFD

06 0035 016B 0000 0000 FFFD FFFD

06 0035 0170 0000 0297 FFFD 12D9

06 0035 016A 0297 0297 12D9 12D9

00 0035 0169 0000 058D FFE8 1951

00 0035 0165 0000 0002 FFF8 0003

...

00 0036 0162 0000 0001 FFF8 0003

P-50 0036 0165 0000 0001 FFFA 0002

06 0036 016F 0000 0000 0002 0002

06 0036 0170 0000 0000 0002 0002

06 0036 0167 0000 02D5 0002 1169

06 0036 0165 02D5 02D5 1169 1169

06 0036 016B 02D5 02D5 1169 1169

00 0036 0169 0000 0555 FFFB 18C0

00 0036 0169 0000 0001 FFF8 0002The status/error/transition code is given in decimal and the rest of the parameters in hexadecimal and these are in turn:

1. Charging (or non-charging, as the clock goes all the time) time

2. The number of circuits of the tight loop of measurements in 100 ms (as you can see, with the transmit on, it no longer makes 400x but about 360x)

3. Minimum voltage

4. Maximum voltage

5. Minimum current

6. Maximum current

... which is the same as what can be shown on the display; only it's hexadecimal, the time is in deciminutes, the voltage in centivolts and the current in milliamps.

Firmware

I guess it was only by using 8051 (CISC) and an assembler that it was possible to stuff all the firmware into a 2 KiB ROM.

There was not enough room for any more extensive Bluetooth control.

Filmish

Charging a charged battery:

Charging a dead battery in auto-recharge mode (which is why this option is disabled by default):

Cool? Ranking DIY