I invite you to a short presentation showing the process of creating a simple 3D printable item. I will design and print a lamp-mounted phone holder that allows you to use your phone vertically. I will show the step by step design process along with test prints.

In a way, this topic will be a continuation of the "phone as microscope" presentation:

Phone as "microscope" and TQFP soldering - step by step video presentation

I simply needed the option to rotate the phone 90 degrees, and the factory kit with the lamp does not offer this.

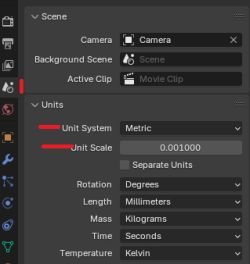

I'll do the design in Blender, although it's not directly designed for this type of application - I'm just familiar with that program. This can be taken as a curiosity, or as an encouragement for people who already know Blender and would like to print something quickly. I won't describe the keyboard shortcuts etc. here, because that wouldn't be practical, I'll focus on the general methodology.

I will print the target piece from PLA filament on an Ender 3 Pro printer.

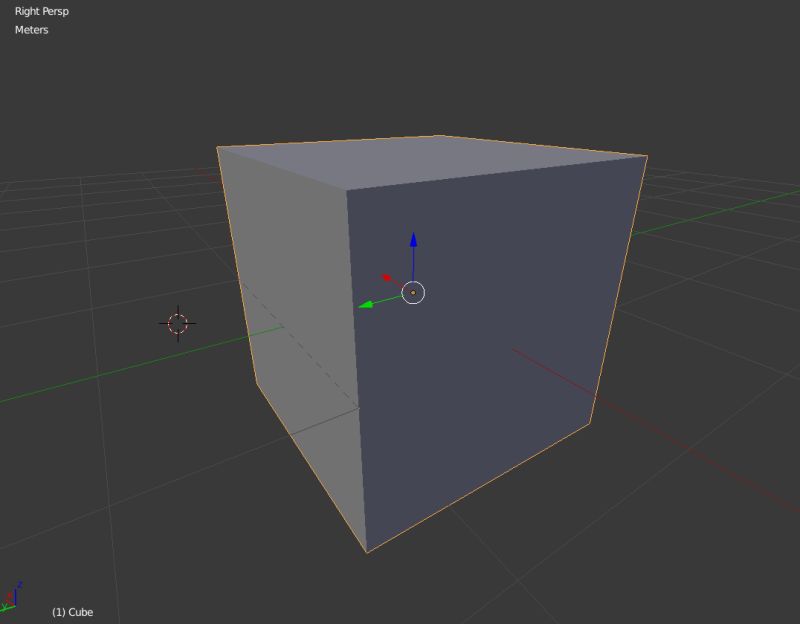

In the beginning there was a cube...

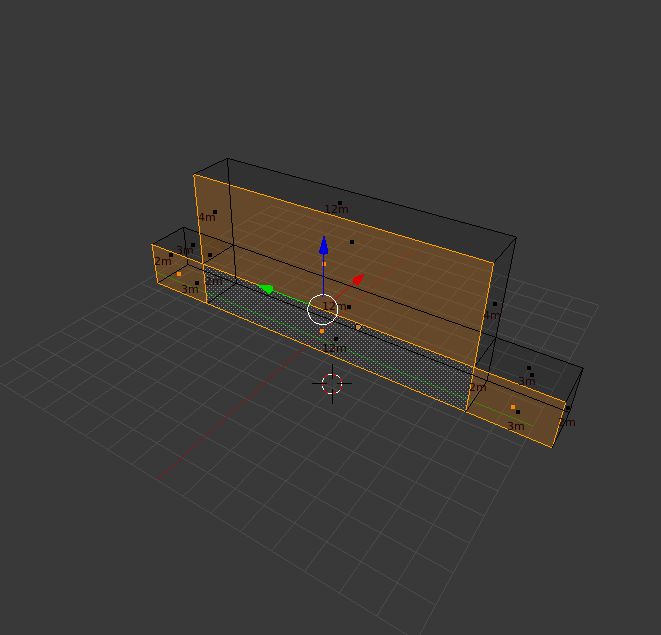

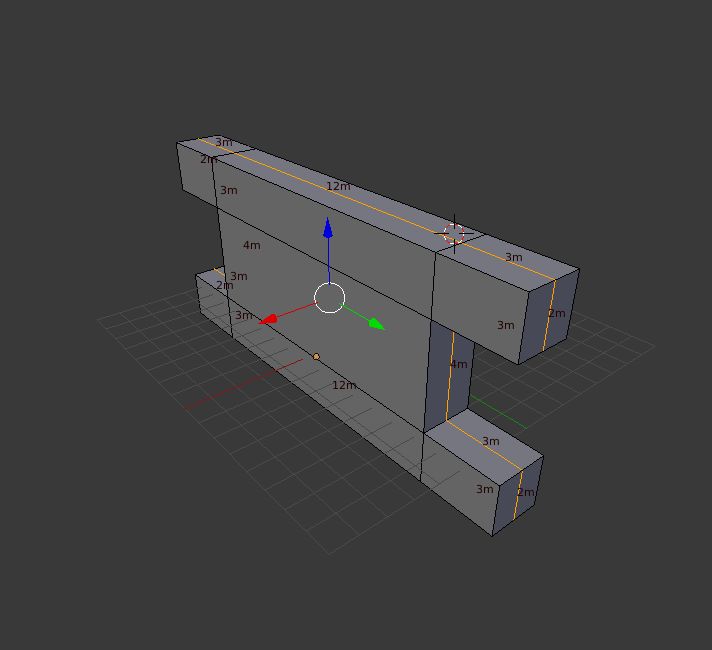

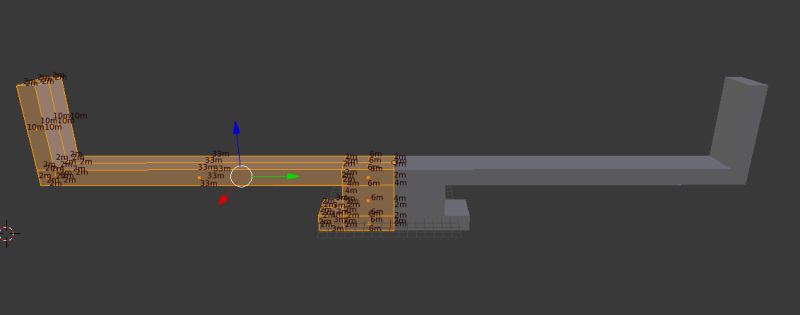

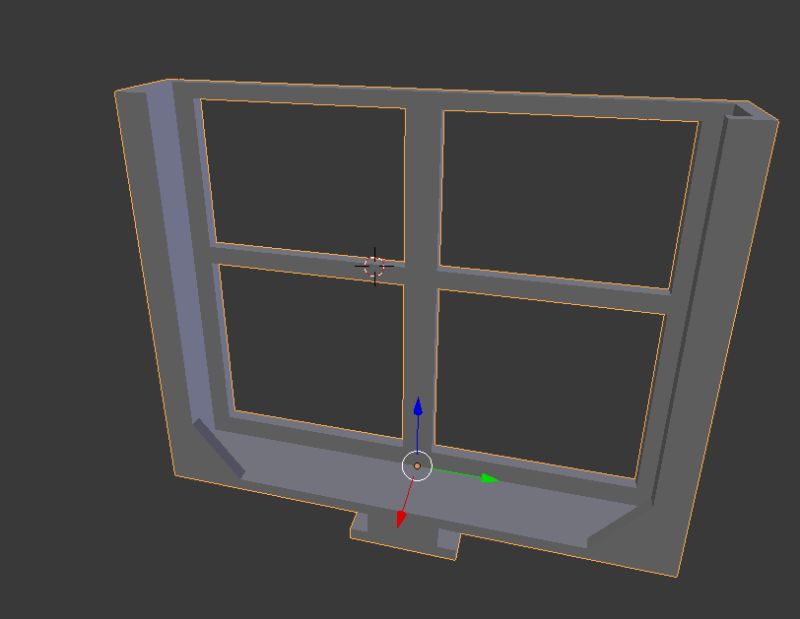

I then dimensioned the indentation I wanted the mount to go into. I used the cheapest caliper. I adjusted the cube to fit, based on the "extrude" operation by the given offset:

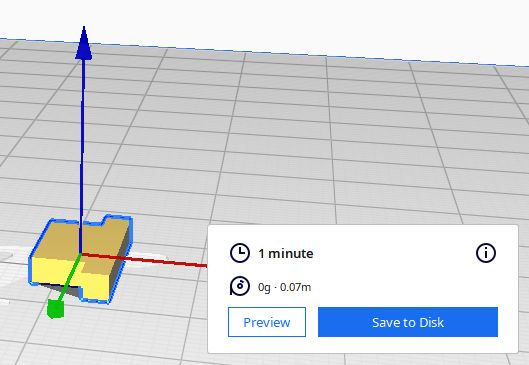

At this stage it was time for a test print. Such a tiny piece will print in a few minutes, and will allow you to check tolerances and actual dimensions.

See how quickly it prints. It also matched up with me straight away:

It fits, it's fine - just in time for the squeeze. You can move on, i.e. make the "protruding" part:

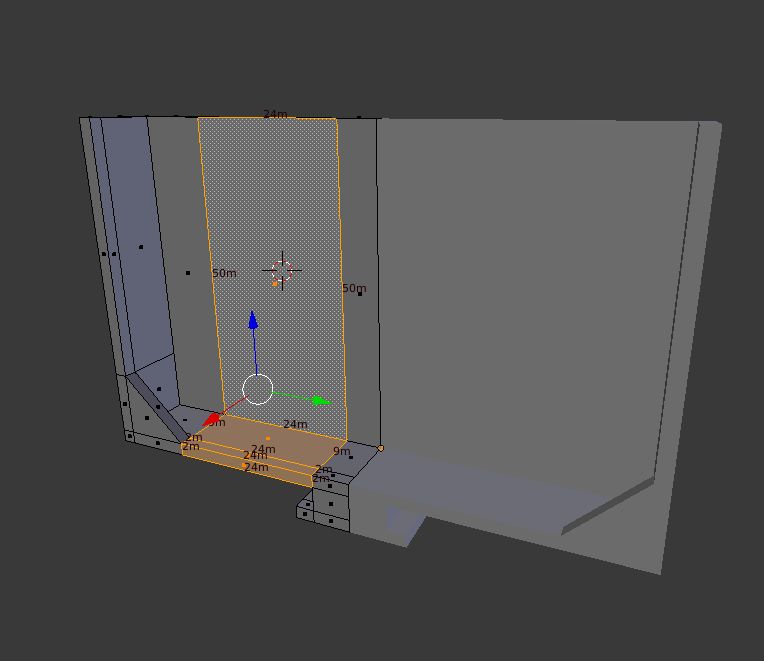

In addition, I partitioned the element separately to have further fields to "extrude". I used "loop cut and slide" for the parting.

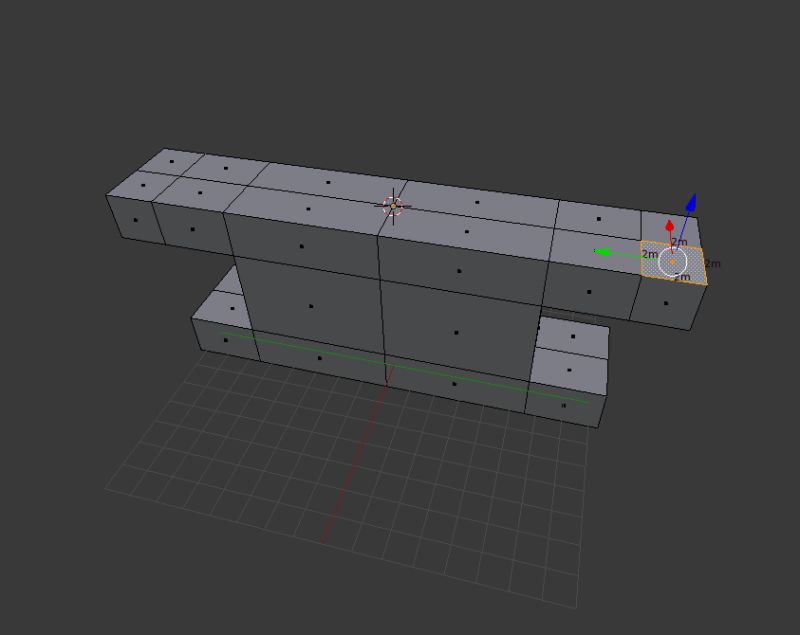

At some point, however, I realised I was adding work to myself and flipped the model into mirror mode. I made sure its centre ('origin') was in the expected location and removed half of it, then added a 'mirror modifier' to recreate that side.

This way I can only edit one page and the other will follow.

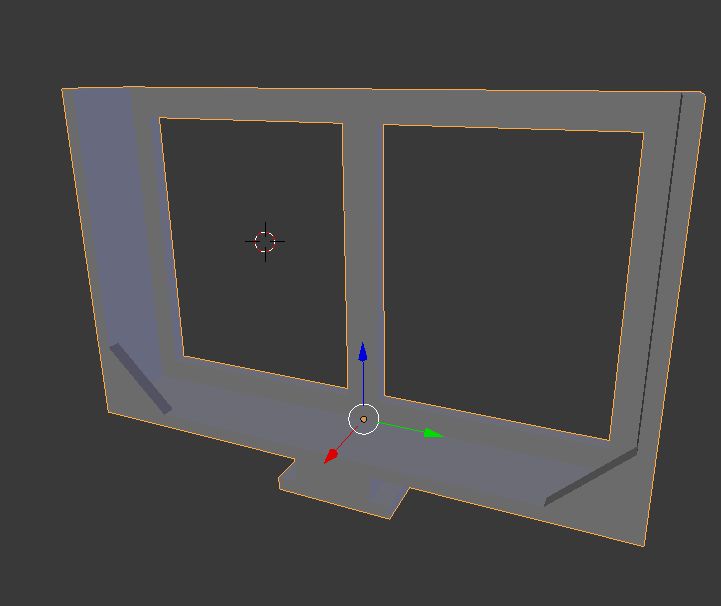

It was time for another print and fitting:

At this stage I have already made a "pocket" for the phone. It has to hold it at least a little on both sides, on the front it can be built in, on the back no longer - because it would obscure the screen.

However, enclosing the pocket at the front can significantly increase the print time and weight of the component. The element is not filled 100%, there is a setting for this in Cura, but it is still worth optimising this manually too. For this reason, I added a separate object - a suitably sized cube - and clipped it using the 'boolean' operation from the created element, or more precisely, set its clipping and did not accept the 'modifier'. In this way, it will be clipped dynamically and will respect the changes I will later implement in the shape.

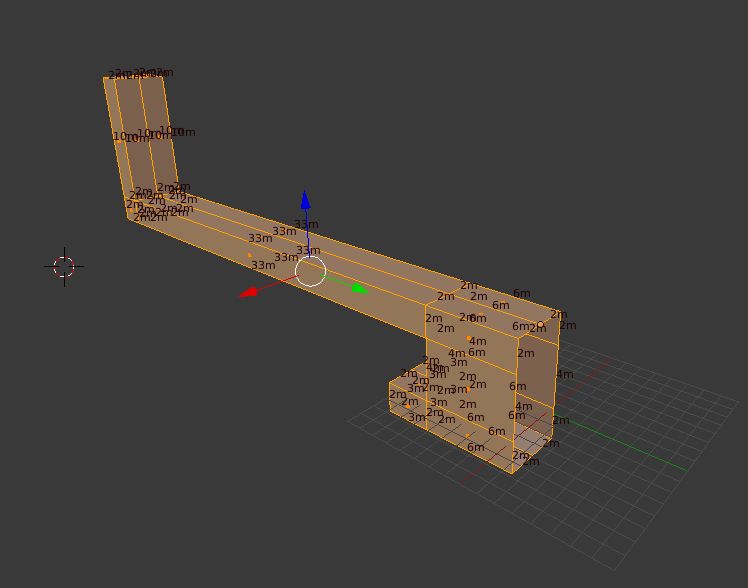

Finally, I duplicated the cube and made minor adjustments:

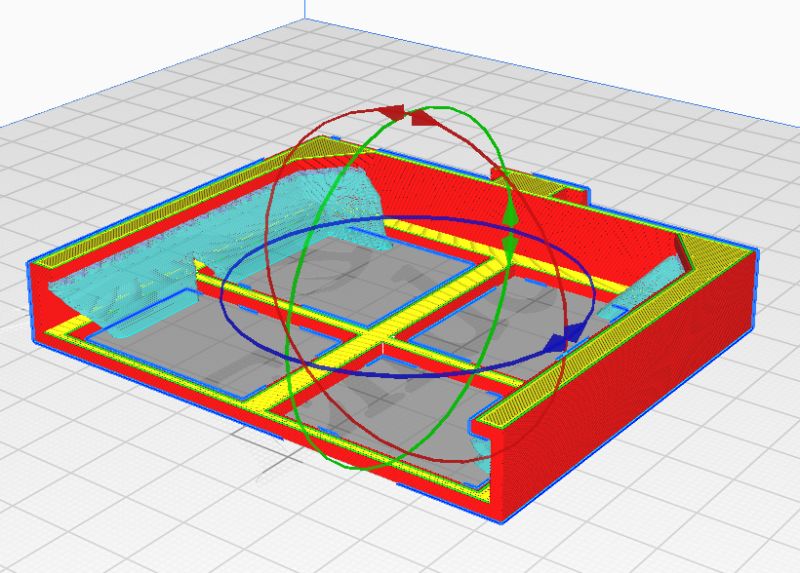

Because of the added "hooks", the piece had to be printed with so-called "supports", or supports. I used "tree supports":

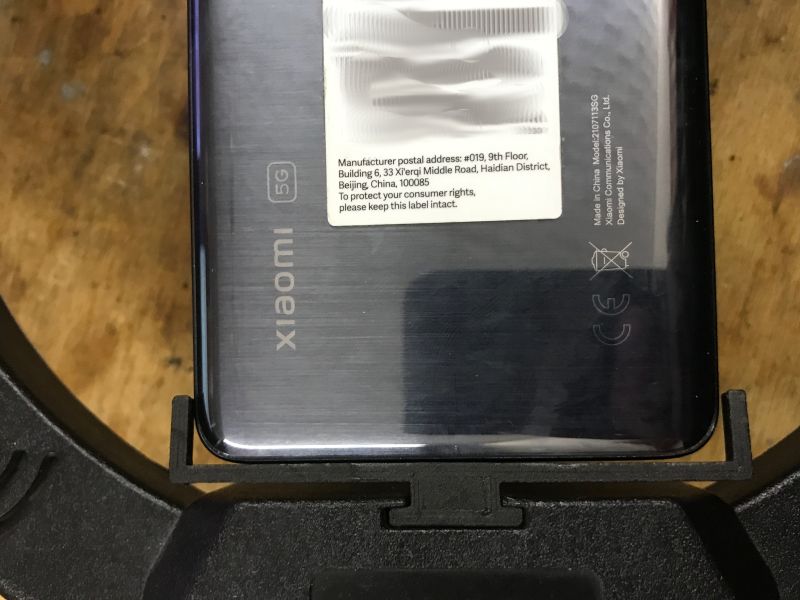

The item fits, but does it hold the phone?

The phone is held well, everything is fitted for the model I am using. You could do a gripper with an adjustment (based on a screw for example), but given the ease of adding a new model as I change phones I decided it wasn't worth the complication.

In summary , this was a brief demonstration of designing a vertical phone holder for the light. From now on, I can shoot videos in vertical format. It remains to be seen how much it cost me:

- time - I didn't count, but it can be chalked up in a few minutes

- energy - basically it's printing time, the final piece prints for an hour and 40 minutes in "Standard quality" (0.2mm), and 20 minutes less in "Draft", for the printer what I have is assumed to be an average of 120 watts of power

- filament - the final piece weighs about 22 grams, 1kg of PLA I buy for £50

The cost of test prints is negligible.

The piece is robust, as the acicular direction of printing is perpendicular to the potential direction of breakage on set up, I'm not worried about its durability.

The project was enjoyable and successful, and I have designed and printed countless gadgets of this type.

And what have you used a 3D printer for recently?

Cool? Ranking DIY Helpful post? Buy me a coffee.