Hello my dears

Today I will describe one of my first projects completed with the help of a 3D printer ( Ender Creality Pro 3 ). This is the attachment piece for the roller shutter Gardinia , according to my own design. This roller blind as I found it is designed to be fixed "on the door" (no drilling, no screwing), so without my piece fixing it to the wall is problematic. I don't know if there are other/better blinds to mount, as I was put to the task of mounting this blind that someone had already bought. The piece I designed fits well with the mounting of this blind and has a suitable screw hole.

The design came about entirely out of practical need, I was helping someone install this roller shutter and this was my solution. Finally, I will post the CAD files of the developed model, so anyone interested can benefit.

Design of 3D model

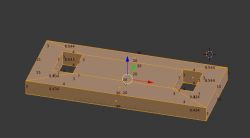

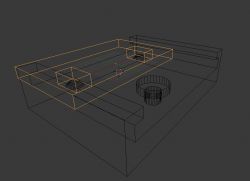

I started by modelling the object that would be attached to my element. I had no intention of printing it. I intended to use it to fit my fixture to existing parts (i.e. as a reference):

I then prepared an already targeted element around it. The screenshot shows both elements and their matching:

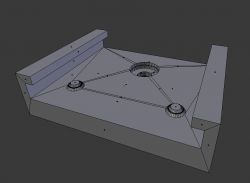

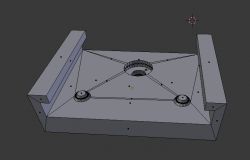

And this is how the final designed element looked like:

And this is the element I have already printed.

Printing the part on 3D printer

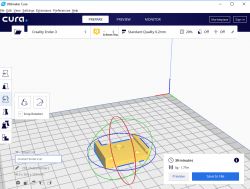

I decided to print the project in Standard Quality mode. The print time was estimated at 39 minutes and the weight at 5 grams.

NOTE: To print an item without the so-called supports (supports) you need to rotate it 90 degrees from how it is shown in the screenshot above. I printed it this way and that way, compared both options and decided that it was better to rotate it and print without supports , than to leave it as it is and print with supports .

It came out reasonably well, although I found that the size of the mounting tabs (the two sticking out slightly) was a bit too big and I had to file them down slightly with a file. Nonetheless, the whole thing held together well as it went in tight.

Final fitting (the white piece from the blind inserted into my 3D printed black mount):

End fixation blinds

I'm not going to judge here the point of fixing the roller shutter where it was fixed. I did what I was asked to do. I just want to show how it was fixed.

I drilled two dowel holes in the wall and then tightened my fixings to it with screws.

Left mount:

Right mount:

Then I have already placed the roller blind in them. The whole thing holds solidly and does its job well:

Additional - leaflet of the roller blind used

For those who are interested, I am posting pictures of the leaflet of the roller shutter for which my bracket was designed. It shows how this roller blind is normally mounted, for example on a door. This roller blind is thoughtfully designed so that it can normally be fixed without tools (even on the instructions there is a crossed out picture of a screwdriver and a screwdriver).

The original way of attaching the blind is quite ingenious, but in my case it didn't work and so I had to come up with something myself.

Summary

The roller blind is holding up solidly and does not promise to have any problems.

The weight and printing time of the component make its cost nearly zero and its usability high (fitting it does not interfere with the other parts of the blind and allows it to be moved to another location later).

Using a 3D printer means that the component can be alternately modified , e.g. if necessary, move the hole slightly upwards by several mm when you want to make adjustments to the mount.

In the future when I have white filament I may re-print this part, but I don't think that will necessarily be the case as so far none of the blind users have paid any attention to the colour of the mount.

I hope that my tiny design described here will motivate someone to take an interest in 3D printing and show that this new trend really can solve a lot of everyday problems.

I am posting the source files of my mount:

Additionally; the same in STL format:

NOTE: After printing, check that the catch from the roller shutter holds well in my mount. It should go in tight.

Cool? Ranking DIY Helpful post? Buy me a coffee.