FAQ

TL;DR: With 3‑core cabling and standard shutter motors, "virtually all automation solutions can be used" for 12 shutters—Wi‑Fi, Z‑Wave, or PLC. [Elektroda, Marek J., post #18571020]

Why it matters: This helps homeowners and installers choose reliable central and smartphone control using existing wiring and appropriate radio coverage.

Quick Facts

- Budget signals: ~PLN 2,000 for 12 basic Wi‑Fi modules vs. ~PLN 3,000–4,000 for richer ecosystems. [Elektroda, TomD2121, post #18567977]

- Motors: Mechanical limit switches and phase‑fed up/down control are compatible with most automation paths. [Elektroda, Marek J., post #18571020]

- Wiring: Extra 3‑core from each switch to a cabinet plus full L/N/PE at switches enables cabinet or coil control. [Elektroda, TomD2121, post #18568647]

- Range: Prefer Z‑Wave or radio paths "with repeaters and two‑way communication" (e.g., Mobilus, Fakro) when Wi‑Fi coverage is uncertain. [Elektroda, Marek J., post #18576813]

- PLC route: Fatek PLC + Ethernet/HMI supports remote control, schedules, and 24 V logic suited to 3×1 cables. [Elektroda, pafciowaw, post #18578185]

What’s the simplest way to add smartphone control to 12 shutters?

Your motors use mechanical limits and phase up/down, so you can choose Wi‑Fi modules, Z‑Wave modules, or a PLC with relays. Pick based on range, wiring practicality, and budget. The motor type does not block these options. Group control and per‑shutter control remain feasible. [Elektroda, Marek J., post #18571020]

Should I centralize everything in a cabinet or use in‑wall modules?

Check the three‑core cable’s cross‑section and insulation first. If the cable is unsuitable for safe control, use in‑wall shutter modules. When wiring supports it, cabinet logic driving relay coils is viable. If not, you “can’t avoid” local modules under switches. [Elektroda, Marek J., post #18572220]

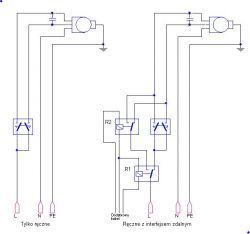

How do I prevent up/down conflicts between local buttons and central commands?

Use interlocking control with two relays. "Relay R1 cuts power to the manual buttons" and handles one direction. Driving R1+R2 commands the opposite direction. Close all with minimal relays; open in groups if needed. Never energize up and down simultaneously; it can damage the motor. [Elektroda, pafciowaw, post #18572105]

Will Wi‑Fi modules have enough range, or should I plan repeaters?

Range concerns are valid in larger or multi‑story homes. Plan for repeaters or choose Z‑Wave mesh‑based devices to improve reliability. If Wi‑Fi remains preferred, ensure strong coverage or additional access points. A mesh solution reduces dead spots for shutter controls. [Elektroda, Marek J., post #18576529]

Why consider Z‑Wave for shutters?

Z‑Wave shutter modules offer mesh coverage and feedback. As noted, options exist "with repeaters and two‑way communication" from brands like Mobilus or Fakro. This improves reliability versus single‑AP Wi‑Fi. It also eases scaling beyond a few devices. [Elektroda, Marek J., post #18576813]

Can a PLC handle this and still keep local wall buttons?

Yes. Use a PLC (e.g., Fatek) with Ethernet or HMI for local and remote control. Program schedules, groups, and scenarios. Drive in‑wall interlock relays via safe 24 V logic over the 3×1 runs. This keeps local buttons and adds central automation. [Elektroda, pafciowaw, post #18578185]

What control mode do my motors use?

They operate on held commands: a maintained up or down contact moves the shutter, and releasing stops it. These are standard tubular motors with mechanical limiters. That mode fits cabinet relays, in‑wall modules, or PLC outputs. [Elektroda, TomD2121, post #18570855]

How do I implement cabinet‑based central control using the 3‑core runs?

- Fit double interlock relays under each local switch to manage up/down safely.

- Use the 3‑core cable to bring each relay’s coil control back to the cabinet.

- In the cabinet, drive coils via PLC outputs or grouped controllers for central commands. [Elektroda, pafciowaw, post #18571180]

How many devices can a Z‑Wave network support if I expand later?

A Z‑Wave network typically supports up to 232 nodes. That headroom suits multi‑room shutter setups and future sensors or scenes. Mesh repeating extends effective coverage as nodes increase. Plan node placement to maximize reliability. [Z‑Wave Alliance, 2023]

What budget should I plan for 12 shutters?

Expect about PLN 2,000 for 12 basic Wi‑Fi shutter modules. More advanced ecosystems or centralized logic may run PLN 3,000–4,000. Costs exclude installation time, relays, and panel hardware. Align your choice with coverage and grouping needs. [Elektroda, TomD2121, post #18567977]

Can I control individual shutters, groups, and all at once from a phone?

Yes. With standard phase‑driven motors and compatible modules, you can build per‑shutter, grouped, and whole‑home scenes. The motor type supports diverse automation paths. Choose the platform that matches your grouping and app needs. [Elektroda, Marek J., post #18571020]

Which controllers fit a 5×1.5 run with bell buttons and a central button?

Pick shutter controllers that accept momentary inputs and offer central or scene control. Z‑Wave modules with mesh repeating suit range‑challenged layouts. Options highlighted include Mobilus and Fakro ecosystems with two‑way radio paths. Map groups to central inputs or scenes. [Elektroda, Marek J., post #18576813]