Hello!

I'm thinking about installing a system for external blinds in our house, and I don't know how to go about it in the best possible way for the future. At the moment, we don't know what kind of blinds or shutters we are going to install in the future, and we will have to install them slowly, as we will be doing the plastering in the autumn.

I have a question about how to fit the wires into the installation:

Downstairs I have 7 windows , at each window I want to have a switch to open and close the blinds ( 1st group).

Upstairs I have 5 windows (2nd group)

In the garage I have 3 windows ( 3rd group)

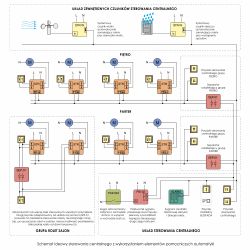

I want to have a switch for each window and a switch for each group to control each group, and in the corridor at the entrance to the house I want to have one main switch to control all the roller shutters (all groups).

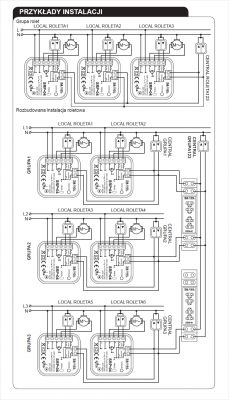

I plan to run the power supply on a separate circuit, using a 3-core 1.5mm cable to each window box, then a 4-core 1.5mm cable from the window box to the motor on the roller shutter, and a 4-core 1.5mm cable from each box back to the group switch. Then connect e.g. these 7 windows in the group switch, so that the group switch closes the group.

Then connect the 4-core 1.5mm cable from each group switch to the central switch at the entrance.

Does it make sense to connect them in boxes in this way or is it better to connect each box to a central unit and connect everything in the central unit and then send it from the central unit to individual group switches and one central switch?

Is a 4-core cable sufficient or would a 5-core cable be better? In future we would also like to control everything via a smartphone.

kind regards

I'm thinking about installing a system for external blinds in our house, and I don't know how to go about it in the best possible way for the future. At the moment, we don't know what kind of blinds or shutters we are going to install in the future, and we will have to install them slowly, as we will be doing the plastering in the autumn.

I have a question about how to fit the wires into the installation:

Downstairs I have 7 windows , at each window I want to have a switch to open and close the blinds ( 1st group).

Upstairs I have 5 windows (2nd group)

In the garage I have 3 windows ( 3rd group)

I want to have a switch for each window and a switch for each group to control each group, and in the corridor at the entrance to the house I want to have one main switch to control all the roller shutters (all groups).

I plan to run the power supply on a separate circuit, using a 3-core 1.5mm cable to each window box, then a 4-core 1.5mm cable from the window box to the motor on the roller shutter, and a 4-core 1.5mm cable from each box back to the group switch. Then connect e.g. these 7 windows in the group switch, so that the group switch closes the group.

Then connect the 4-core 1.5mm cable from each group switch to the central switch at the entrance.

Does it make sense to connect them in boxes in this way or is it better to connect each box to a central unit and connect everything in the central unit and then send it from the central unit to individual group switches and one central switch?

Is a 4-core cable sufficient or would a 5-core cable be better? In future we would also like to control everything via a smartphone.

kind regards