The 3D printer is a subject that has interested me for a long time. I thought my own 3D printer was completely out of my reach, until I had my first exposure to an Anycubic Photon resin printer that I got for repair. Once the equipment was up and running I was able to play around with printing. I went nuts

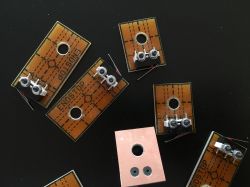

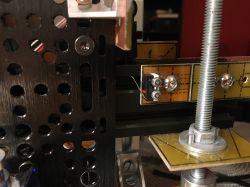

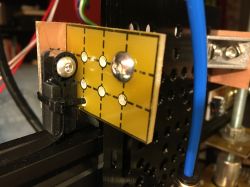

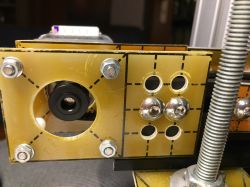

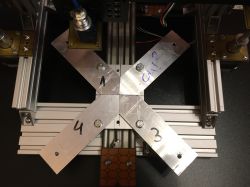

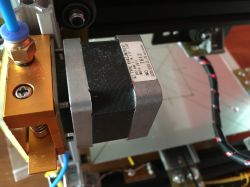

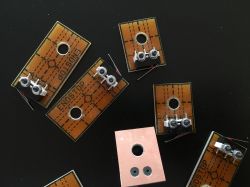

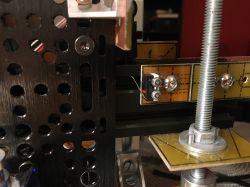

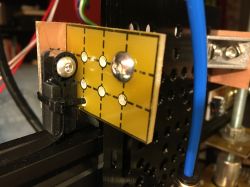

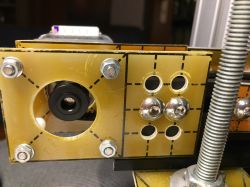

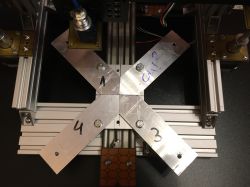

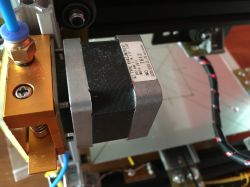

However, the time to print a part took too long for me, so I became interested in the subject of filament printers. I had a couple of T2040 and v-slot profiles in stock with rollers and gantry plates, so I set about bolting them together. I also had a 'sample' linear guide with carriage from IGUS-this was my Y-axis. I purchased a BigTreeTech SKR1.3 controller with TFT43 display and TMC2208 3.0 UART motor drivers. The stepper motors had been lying in my cupboard for a few years. Now they have come in handy. For the Z-axis I used M8 threaded rods (ordinary, rolled ones from the market). I made all the necessary motor mounts, belt tensioners (and more) from FR4 2mm laminate. I bought an MK8 extruder and a HOTEND E3D v6 and a few small things and after a few days the launch took place. I should add that I had originally thought of an experimental design based on old CD-ROM drives, but I now know that this would have been pointless due to the very slim possibilities. The printer, after a quick calibration of the table, extruder and Z-axis, started working perfectly immediately (perfectly for an amateur design built "on the knee"). Today this machine is in the process of being expanded, on components printed by itself

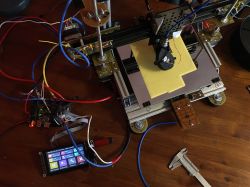

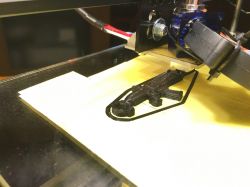

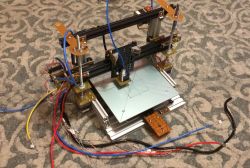

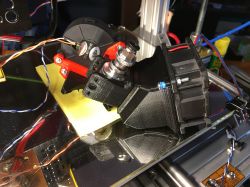

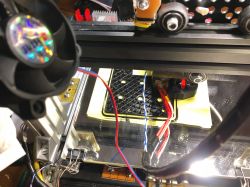

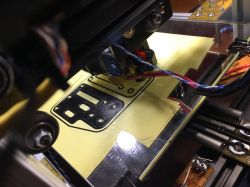

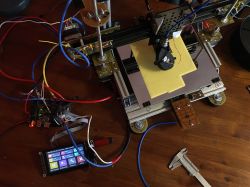

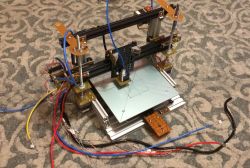

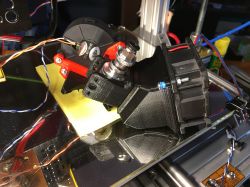

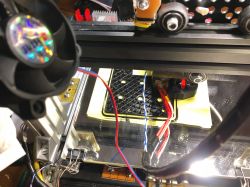

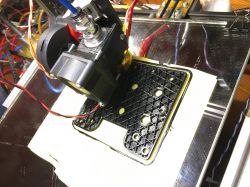

However, the time to print a part took too long for me, so I became interested in the subject of filament printers. I had a couple of T2040 and v-slot profiles in stock with rollers and gantry plates, so I set about bolting them together. I also had a 'sample' linear guide with carriage from IGUS-this was my Y-axis. I purchased a BigTreeTech SKR1.3 controller with TFT43 display and TMC2208 3.0 UART motor drivers. The stepper motors had been lying in my cupboard for a few years. Now they have come in handy. For the Z-axis I used M8 threaded rods (ordinary, rolled ones from the market). I made all the necessary motor mounts, belt tensioners (and more) from FR4 2mm laminate. I bought an MK8 extruder and a HOTEND E3D v6 and a few small things and after a few days the launch took place. I should add that I had originally thought of an experimental design based on old CD-ROM drives, but I now know that this would have been pointless due to the very slim possibilities. The printer, after a quick calibration of the table, extruder and Z-axis, started working perfectly immediately (perfectly for an amateur design built "on the knee"). Today this machine is in the process of being expanded, on components printed by itself  but I would like to present what was then created driven by dreams. At the time, as it was a prototype, I didn't think about tidying up the cables - I put everything together on a table and the first prints were created under these conditions.

but I would like to present what was then created driven by dreams. At the time, as it was a prototype, I didn't think about tidying up the cables - I put everything together on a table and the first prints were created under these conditions.

edit: some more photos:

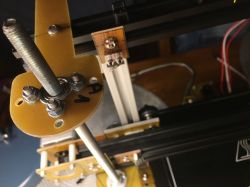

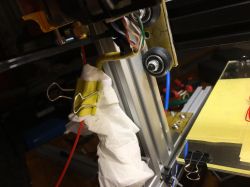

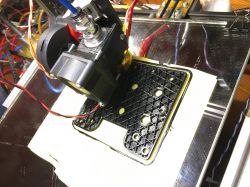

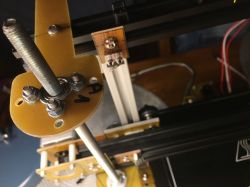

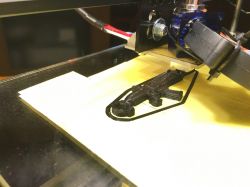

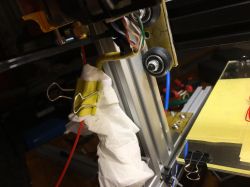

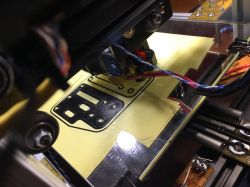

i made a primitive filament cleaner out of a tissue and clipped it with a paper clip

edit: some more photos:

i made a primitive filament cleaner out of a tissue and clipped it with a paper clip

Cool? Ranking DIY