Hello my dears.

The defect of a cracking plastic extruder arm is rather familiar to any long-term user of the Ender 3 printer. Virtually every plastic extruder arm cracks and quickly becomes unusable. As a rule, the extruder is then replaced with its aluminium counterpart, but here I would like to present an alternative to this choice, the 'dual gear extruder' - an extruder with two cogs (double knurl), providing more precise and more robust filament guidance. I will outline its installation here and describe my impressions a few months after replacement.

Introduction

My first original extruder came to a poor end after less than six months of use:

I then replaced it with its classic aluminium counterpart:

Overall, it wasn't too bad, although after prolonged use I felt that there were some difficulties in properly calibrating the tension of the spring that presses the movable arm against the bearing.

After some time I heard positive feedback about the dual gear extruder and decided to try it out:

In the end, however, I bought it in our country. It is time to describe its installation.

Installing the dual gear extruder

Installing this extruder requires unscrewing the stepper motor (when unscrewing, hold it so it doesn't fall), as well as removing the gear from the motor shaft (it's held on by a small screw), and (of course) removing the bowden tube.

Below are some photos of the assembly.

Kit:

Kit contents:

Bearing and arm assembly:

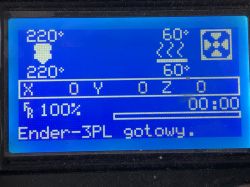

Before removing the old extruder, of course we warm up the hot end to remove the filament (we do not remove the filament "cold" by pulling it out by force, I hope we know that this is not the right thing to do):

Disassembly of the previous extruder. You can clean everything by the way:

If you unscrew these screws the engine will drop. It needs to be held in place.

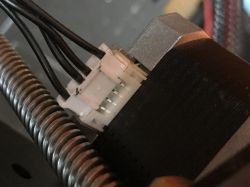

Disconnect the cables:

I used a trace amount of WD40 to lubricate the bearings (the two black parts shown in the photo) as I didn't have anything better at hand, although I know it's not a good solution (lithium grease, for example, would be better):

Removing the cog from the extruder stepper motor shaft. The little black screw needs to be removed:

Remember to use screws with a flat head (otherwise the extruder arm will snag on it):

Dual gear extruder base pre-screwed already with motor:

Prepared cog for the motor shaft (small screw visible at the end of the screwdriver):

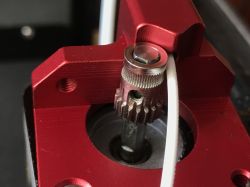

Adjusting the height of the cog. It must be in line with the line of the filament (I put white in the bowden tube for a test):

Only after levelling do we press the cog onto the motor shaft with the screw.

Assembly of the movable arm. The second cog must be at the height of the first one:

Tightening the screw (first we need the one in the photo holding to the motor base):

Done:

Necessary step - e-steps calibration

Calibrating e-steps is a very simple process.

I had not originally planned to describe it here, but since it is essential, I will nevertheless attempt to detail it here.

Calibrating e-steps involves 'teaching the printer' how many steps the extruder motor needs to take to extrude 1mm of filament.

This value varies depending on many factors, extruder settings, etc.

Some people calibrate this via software to a computer and communicate with the printer via UART, to this they use ready-made Excel sheets to do the calculations, etc., I will show here the simplest, traditional way.

We need:

- a piece of filament

- calliper (to measure the length of the filament; precision is important)

- marker (to mark the place on the filament)

- calculator

1. Measure a distance of 100mm from the extruder filament entrance and mark it on the filament. Then measure an additional 120mm from the entrance of the filament and mark this too. This is in case the extruder pulls in the whole 100mm.

2. We heat the printer to the correct temperature for the filament

3. We extrude 100mm (or at least in theory 100mm, because in practice how much will come out is about to be checked and then calibrated).

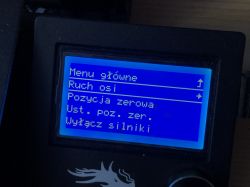

Prepare->Move axis->Extrusion (axis E)->Move every 1mm

4. We check how much has actually been extruded (we measure the new distance from the extruder input). This distance, of course, tells us how much extruded filament is left, not how much came out, so if there is, say, 25mm left to the 120mm point, then we know that 95mm has been extruded.

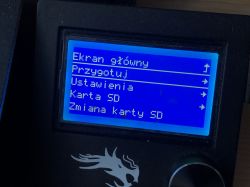

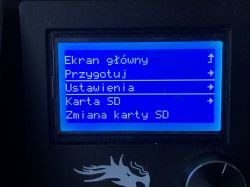

5. We check the current value of the e-steps.

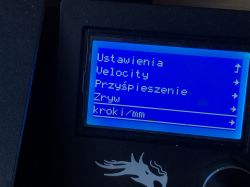

Settings->Motion->steps->E-steps.

In my case it was the default 95:

6. We calculate the new e-steps value according to the formulas:

100 * CurrentValueESteps = X (number of steps needed to extrude 100mm of filament)

New_ESteps = X / MeasuredLengthExtrudedFilament

For example:

CurrentStepsValue = 95

100 * 95 = 9500 (number of steps needed to extrude 100mm of filament)

MeasuredLengthExtrudedFilament = 64.5mm (actually 64.5mm of filament just passed through)

New_ESteps = 9500 / 64.5

New_ESteps = 147.3

(we can leave the values after the decimal point, as far as I know the firmware supports them)

7. Set new E-steps

Settings->Motion->steps->E-steps.

8. Save changes to EEPROM

We save the calculated value also outside the printout

We save the calculated value also outside the printout

We save the calculated value also outside the printer, on a piece of paper, in case we reset the EEPROM.

9. Repeat the process, points 1-8 (at least once, also to verify that we have set it correctly)

NOTE: If you have the bowden tube removed then you don't even need to do the "with a pen" method, basically you can cut the filament right at the extruder exit, do a 100mm extrusion and measure how much of that filament came out. This is equivalent to what I have described.

NOTE: It is worth knowing that the esteps setting command can also be added to our gcode exported from the slicer, in which case it overwrites the printer setting.

NOTE: The printer may have a safety feature that blocks extruder control when the hot end is not warmed up. If this happens, simply warm it up.

Summary

After fitting the dual gear extruder I specifically waited a good 4 months of printing (and the printer works for me a lot) to finally give a verdict. I didn't want to judge in advance, and additionally I waited until the famous "rubbing" of the cog against the arm appeared, however it didn't happen at all in my case, even though I took a relatively cheap (cheapest?) dual gear extruder.

Perhaps this is because I raised both cogs appropriately and matched their height to the filament line.

In any case - revelation . The quality and convenience of prints has permanently improved. Previously, I had occasional problems with the bowden, sometimes with the hot end, every few weeks I had to unplug it, or I saw, for example, that the extruder motor "ticks" (loses steps, 'extruder skipping'), or even the filament slips, extrusion or retraction does not extend/retract the filament as much as the printer would expect (and I had calibrated e-steps)....

And now the problems are practically non-existent - this new extruder solidly holds and feeds the filament, it is not afraid of possible dirt or there older spools of plastic. I regret that I did not buy it earlier.

I don't know if your experiences are similar, but I still have to add something at the end - NOTE - swapping to a dual gear extruder should obviously not be used as an alternative to removing heat creep, levelling the table or cleaning the nozzle there. The table has to be leveled anyway, as well as the bowden should be properly fixed, etc. etc. The printer must be taken care of.

Cool? Ranking DIY Helpful post? Buy me a coffee.