I have been involved with HA for a relatively short time. My experience closes in putting up HA as a Docker on Debian and integrating a few basic devices (PV inverter, air fresheners, garden watering system, in order to log the parameters in the InfluxDB database and thesis pushing out the PV installation params to the PV monitor service.

I would like to include the parameters of the condensing furnace, i.e. mainly CH output temp, CH return temp, DHW temp. The furnace is Immergas Vitrix Superior 26kW ERP2 . I was thinking of two possibilities, one of which seems to me to be a total abstraction and rather impossible to jump through without help:

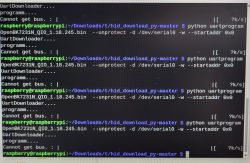

1. the cooker already has some automation, there is a controller connected to it by cable and the controller can do quite a lot, including scheduling DHW and CH separately. It shows the DHW tank temp, supply temp, return temp, you can change a lot of settings with this controller, hence I thought that since the furnace exchanges information with the controller via cable, it could also exchange this information with the HA, but I couldn't find any ready-made Immergas integration among web resources. Hence the idea of programming this from scratch, but I don't even know how to go about it and how, with what, to eavesdrop on this controller protocol to extract the information I need. In addition, you'd need to make some kind of translator that would send the information over the network to the HA and such a thing is probably done on a RaspberryPI or Audriuno (if I'm typing silly things, forgive me).

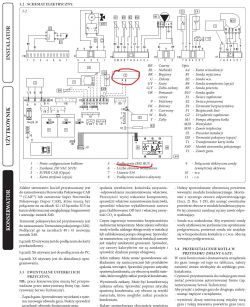

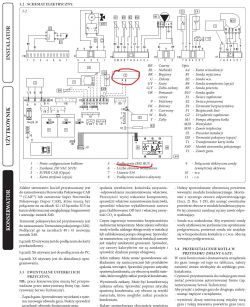

As well as a connector on the motherboard for the controller, the oven also has some sort of connector for the BUS, but as there is no documentation available on this other than the one diagram below, it's hard to see what this is for.

.

.

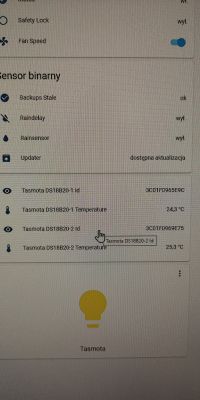

2 Well the other plan is to invest in some WiFi gateway , which will allow me to bring out a couple of cheap thermistors that I can attach to the plumbing pipes and thus send measurements to HA over their network. This seems easier to me and, although poorer than full integration with the furnace, is sufficient for me. Do you know of any low-cost solutions for such temp measurements that you could recommend that would not cause a problem to integrate with the HA?

Thanks for your help.

I would like to include the parameters of the condensing furnace, i.e. mainly CH output temp, CH return temp, DHW temp. The furnace is Immergas Vitrix Superior 26kW ERP2 . I was thinking of two possibilities, one of which seems to me to be a total abstraction and rather impossible to jump through without help:

1. the cooker already has some automation, there is a controller connected to it by cable and the controller can do quite a lot, including scheduling DHW and CH separately. It shows the DHW tank temp, supply temp, return temp, you can change a lot of settings with this controller, hence I thought that since the furnace exchanges information with the controller via cable, it could also exchange this information with the HA, but I couldn't find any ready-made Immergas integration among web resources. Hence the idea of programming this from scratch, but I don't even know how to go about it and how, with what, to eavesdrop on this controller protocol to extract the information I need. In addition, you'd need to make some kind of translator that would send the information over the network to the HA and such a thing is probably done on a RaspberryPI or Audriuno (if I'm typing silly things, forgive me).

As well as a connector on the motherboard for the controller, the oven also has some sort of connector for the BUS, but as there is no documentation available on this other than the one diagram below, it's hard to see what this is for.

.

.

2 Well the other plan is to invest in some WiFi gateway , which will allow me to bring out a couple of cheap thermistors that I can attach to the plumbing pipes and thus send measurements to HA over their network. This seems easier to me and, although poorer than full integration with the furnace, is sufficient for me. Do you know of any low-cost solutions for such temp measurements that you could recommend that would not cause a problem to integrate with the HA?

Thanks for your help.