Hello my dears.

Here I will present what I think is the smallest practical 3D print for an electronics engineer that I have found myself using in a big way, a bit adapter for a small cordless screwdriver. It all started when I got a faulty screwdriver to repair, obviously without any bits and with a dead battery. I replaced the cell inside with an 18650, along with a module for charging directly from a micro USB (very convenient!), but I had a bigger problem with the bits - none of mine fit this screwdriver (not only did they not stick, they fell in too deep, with barely a tip sticking out). To that end, I designed a tiny adapter, which I'll present here.

Adapter design

Bit without adapter in screwdriver:

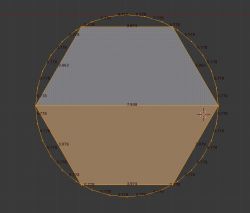

The thickness of the bit socket is 5/16" (approximately 0.79375cm).

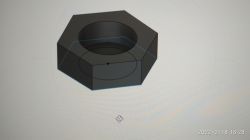

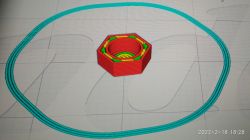

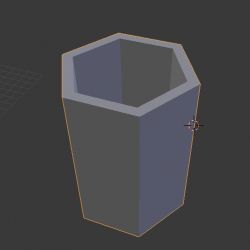

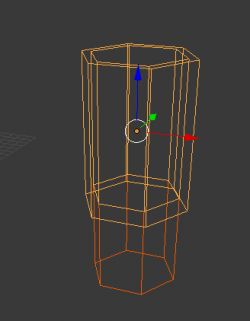

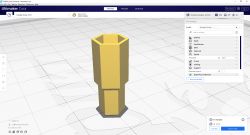

I made the model in Blender:

I selected the thickness on the screwdriver side so that it would go in tight and hold solidly, as I will not be changing it. On the bit side I relied heavily on the magnet.

The weight of the print is a mere 1g:

I used PLA filament. I printed on my Ender 3 PRO.

I didn't get the dimensions right the first time and had to print twice, but with the price of the filament and the size of this object it's pennies.

Now it's time for the magnet - without it it wouldn't make sense. as the bits would fall out of the adapter:

Attaching the magnet with a dropout:

Finished:

The adapter does its job perfectly, the magnet holds the bits, you can unscrew and screw in. The more protruding bit makes it easier to access the screw head.

Summary

These types of simple prints really show the beauty and usefulness of having a 3D printer (combined with knowing the basics of object modelling). What impressed me about this print is that the cost really is extremely small (it's just 1 gram of filament, at £50 per kg that's pennies) and the usefulness is very high. Literally after half an hour I could already be screwing!

A screwdriver like this would normally go in the rubbish, but by converting it to 18650 with USB charging and printing this adapter, its life will be greatly extended.

I am continually impressed by how useful and widely available 3D printing is in our time and just wonder what will be around in 10, 20 years?

Meanwhile, a question for you - what have you managed to print that is practical and at the same time extremely cheap/lightweight, such that it was very useful and at the same time cost pennies?

PS: Of course I also have a full-fledged Makita clone with much more power, but such a small DIY toy charged from USB is sometimes more handy and e.g. faster for me to reach for it to e.g. remove a few screws from a PC case.

Cool? Ranking DIY Helpful post? Buy me a coffee.