The global automotive market has witnessed a rapid demand surge for electric vehicles (EVs) over the past two years, and the market is expected to experience continuous double-digit growth over the next five years.

However, to become a viable alternative to the currently dominant internal-combustion-engine–based vehicles, next-generation EVs need a longer range, faster charging capability and higher power output. To address this, the EV battery architecture needs higher voltage; hence, the shift from the currently used 400 V to 800 V (or higher) is inevitable.

The main benefits of shifting from 400 V to 800 V are:

• A 50% reduction in charging times due to a higher charging power output of up to 350–360 kW. With superfast charging speeds, there would be no need for batteries with a 1,000-km range.

• The lower current required for charging results in reduced overheating and better power retention.

• Even though the majority of EVs on the market run on 400-V battery systems, the transition to 800-V systems is expected to be rapid in the coming years, and by 2027–2030, more than 90% of EVs are likely to have 800-V battery systems.

Even though 800-V EVs are at a very early stage of commercialization, some automakers already sell 800-V EV systems

WBG semiconductors

With 400-V EVs, silicon (Si)-based power devices like MOSFETs and IGBTs have reached their theoretical performance limits. Consequently, to support the transition to 800-V battery architecture, newer materials like wide-bandgap (WBG) semiconductors are needed.

Silicon carbide (SiC) and gallium nitride (GaN) are two WBG semiconductors that are gaining momentum in EVs for applications like traction inverters, on-board chargers and DC/DC converters. SiC is considered inevitable for 800-V battery systems in EVs.

SiC in traction inverters

One of the most important EV systems that governs overall vehicle performance is the traction inverter. In EVs, the main functions performed by the traction inverter are:

• To convert DC from the high-voltage battery to AC for the traction motor

• To convert AC back to DC for regenerative braking

• To control the EV motor speed based on the accelerator inputs by the driver

Development of SiC-based traction inverters that can handle 800 V is now the main area of focus.

An EV drivetrain that can handle 800 V is made faster, more effective and lighter by using SiC MOSFETs. When opposed to Si, SiC creates less heat, is less sensitive to temperature and allows for more effective power switching. Because less heat is released, cooling systems can be lighter and the inverter’s footprint can be reduced.

While the high critical field voltage greatly lowers the on-resistance, the greater bandgap in SiC results in reduced leakage currents at high temperatures, enabling smaller/thinner devices. This enhances current-carrying capacity, reduces switching losses and permits quicker switching.

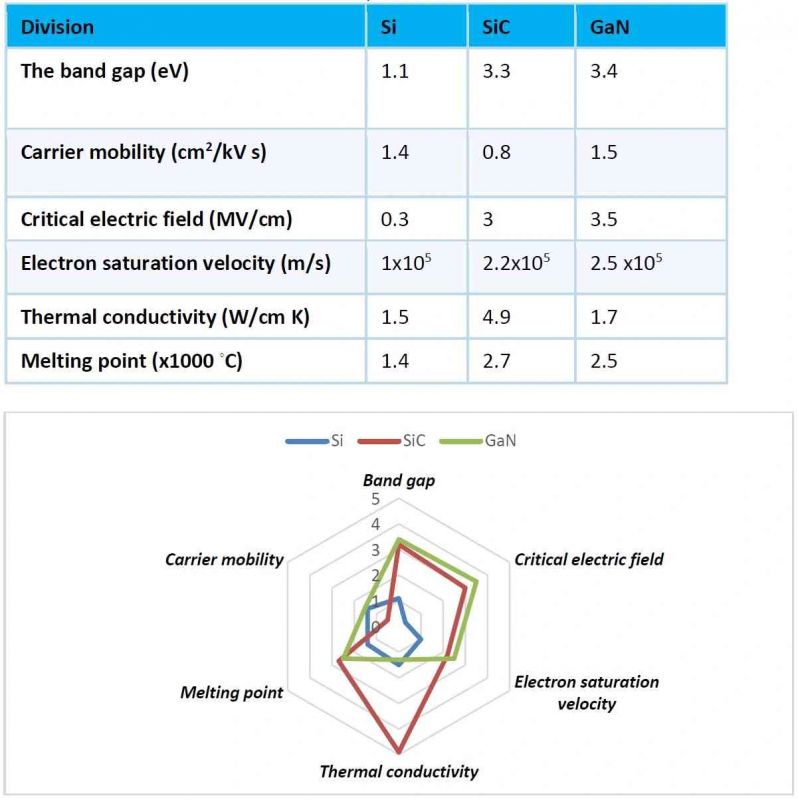

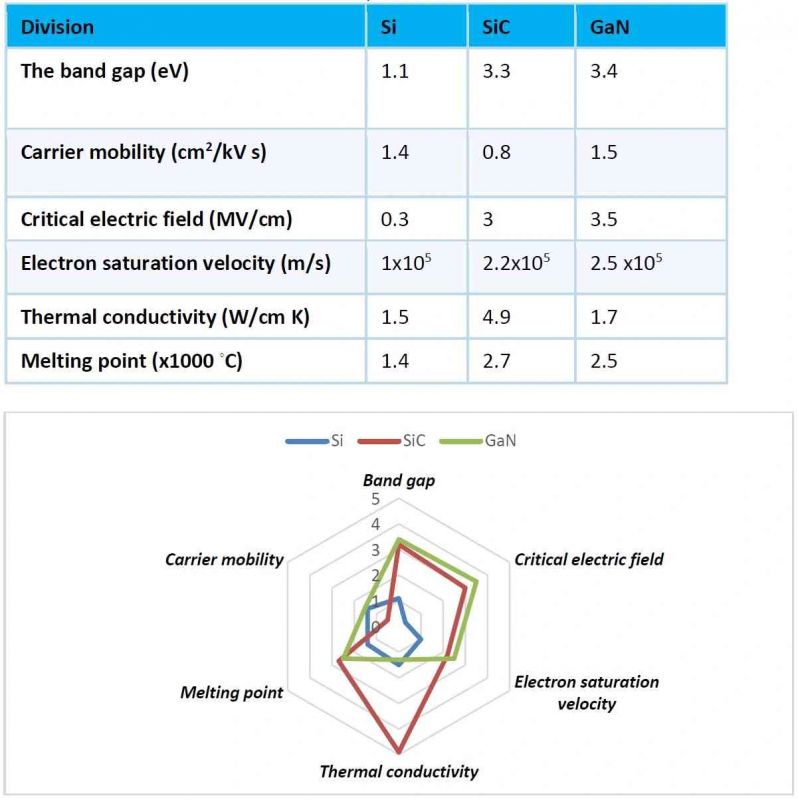

Another crucial area where SiC excels is thermal conductivity, as SiC modules can withstand junction temperatures of up to 200˚C. GaN is still in its very early phases of development and has just recently been used in 800-V EV applications. Figure 1 compares the material characteristics of Si, SiC, and GaN.

Figure 1: Comparison of the properties of Si, SiC and GaN materials

GaN for 800-V EV applications

GaN outperforms SiC in terms of bandgap, critical electric field and saturation velocity. The utilization of this material in high-power and high-temperature applications, such as EV traction inverters, is complicated by its limited thermal conductivity.

GaN’s ideal voltage range for use in 400-V EV systems, which are largely dominated by Si-based semiconductors, is 650-V modules. GaN loses efficiency, though, when the voltage rises to 800 V because of its reduced thermal conductivity.

The existing lateral GaN structure requires a larger die size to achieve higher voltages, which is not practical from a scaling perspective. To accommodate high-power EV applications, the industry is attempting to create vertical/3D GaN structures. To make GaN FETs practical for 800-V EV applications, a number of industry innovators are attempting to increase the efficiency of GaN devices through developments including vertical GaN structures and improved packaging technologies in lateral structures.

Although the transition to 800-V EVs is inevitable for obvious reasons, it’s crucial to remember that 400-V systems will not be phased out. Cost-sensitive markets are anticipated to use 400-V EVs. Additionally, due to the new efficiency standards set by several nations worldwide, even EVs with 400-V battery systems may eventually need to switch to SiC. Due to its heat resistance, low on-resistance and quicker switching than Si, SiC boosts the driving mileage per kilowatt-hour by roughly 5% to 10%.

Conclusion

Right now, SiC is the best option for manufacturers due to its technological characteristics. Due to its poor heat conductivity and lateral structure, GaN, a relatively new and specialized technology, is currently used in only a few EV power applications. But it’s anticipated that technological developments like vertical GaN structures and better packaging will open up a sizable market for GaN in 800-V EV traction inverters.

Due to the strict pollution and efficiency standards set by nations worldwide, top-end 400-V EVs may soon adopt WBG-based traction inverters. In the long run, SiC and GaN technologies would take over for entry- and mid-level 400-V EVs, mostly in cost-sensitive regions.

Read the original article here.

After reading this article, what are your feelings about 800-V EV architecture?

Will most carmakers shift to 800-V EV bus, allowing customers to take advantage of this technology?

Are fast-charging stations a key factor to accelerate the adoption of EVs?

However, to become a viable alternative to the currently dominant internal-combustion-engine–based vehicles, next-generation EVs need a longer range, faster charging capability and higher power output. To address this, the EV battery architecture needs higher voltage; hence, the shift from the currently used 400 V to 800 V (or higher) is inevitable.

The main benefits of shifting from 400 V to 800 V are:

• A 50% reduction in charging times due to a higher charging power output of up to 350–360 kW. With superfast charging speeds, there would be no need for batteries with a 1,000-km range.

• The lower current required for charging results in reduced overheating and better power retention.

• Even though the majority of EVs on the market run on 400-V battery systems, the transition to 800-V systems is expected to be rapid in the coming years, and by 2027–2030, more than 90% of EVs are likely to have 800-V battery systems.

Even though 800-V EVs are at a very early stage of commercialization, some automakers already sell 800-V EV systems

WBG semiconductors

With 400-V EVs, silicon (Si)-based power devices like MOSFETs and IGBTs have reached their theoretical performance limits. Consequently, to support the transition to 800-V battery architecture, newer materials like wide-bandgap (WBG) semiconductors are needed.

Silicon carbide (SiC) and gallium nitride (GaN) are two WBG semiconductors that are gaining momentum in EVs for applications like traction inverters, on-board chargers and DC/DC converters. SiC is considered inevitable for 800-V battery systems in EVs.

SiC in traction inverters

One of the most important EV systems that governs overall vehicle performance is the traction inverter. In EVs, the main functions performed by the traction inverter are:

• To convert DC from the high-voltage battery to AC for the traction motor

• To convert AC back to DC for regenerative braking

• To control the EV motor speed based on the accelerator inputs by the driver

Development of SiC-based traction inverters that can handle 800 V is now the main area of focus.

An EV drivetrain that can handle 800 V is made faster, more effective and lighter by using SiC MOSFETs. When opposed to Si, SiC creates less heat, is less sensitive to temperature and allows for more effective power switching. Because less heat is released, cooling systems can be lighter and the inverter’s footprint can be reduced.

While the high critical field voltage greatly lowers the on-resistance, the greater bandgap in SiC results in reduced leakage currents at high temperatures, enabling smaller/thinner devices. This enhances current-carrying capacity, reduces switching losses and permits quicker switching.

Another crucial area where SiC excels is thermal conductivity, as SiC modules can withstand junction temperatures of up to 200˚C. GaN is still in its very early phases of development and has just recently been used in 800-V EV applications. Figure 1 compares the material characteristics of Si, SiC, and GaN.

Figure 1: Comparison of the properties of Si, SiC and GaN materials

GaN for 800-V EV applications

GaN outperforms SiC in terms of bandgap, critical electric field and saturation velocity. The utilization of this material in high-power and high-temperature applications, such as EV traction inverters, is complicated by its limited thermal conductivity.

GaN’s ideal voltage range for use in 400-V EV systems, which are largely dominated by Si-based semiconductors, is 650-V modules. GaN loses efficiency, though, when the voltage rises to 800 V because of its reduced thermal conductivity.

The existing lateral GaN structure requires a larger die size to achieve higher voltages, which is not practical from a scaling perspective. To accommodate high-power EV applications, the industry is attempting to create vertical/3D GaN structures. To make GaN FETs practical for 800-V EV applications, a number of industry innovators are attempting to increase the efficiency of GaN devices through developments including vertical GaN structures and improved packaging technologies in lateral structures.

Although the transition to 800-V EVs is inevitable for obvious reasons, it’s crucial to remember that 400-V systems will not be phased out. Cost-sensitive markets are anticipated to use 400-V EVs. Additionally, due to the new efficiency standards set by several nations worldwide, even EVs with 400-V battery systems may eventually need to switch to SiC. Due to its heat resistance, low on-resistance and quicker switching than Si, SiC boosts the driving mileage per kilowatt-hour by roughly 5% to 10%.

Conclusion

Right now, SiC is the best option for manufacturers due to its technological characteristics. Due to its poor heat conductivity and lateral structure, GaN, a relatively new and specialized technology, is currently used in only a few EV power applications. But it’s anticipated that technological developments like vertical GaN structures and better packaging will open up a sizable market for GaN in 800-V EV traction inverters.

Due to the strict pollution and efficiency standards set by nations worldwide, top-end 400-V EVs may soon adopt WBG-based traction inverters. In the long run, SiC and GaN technologies would take over for entry- and mid-level 400-V EVs, mostly in cost-sensitive regions.

Read the original article here.

After reading this article, what are your feelings about 800-V EV architecture?

Will most carmakers shift to 800-V EV bus, allowing customers to take advantage of this technology?

Are fast-charging stations a key factor to accelerate the adoption of EVs?

Cool? Ranking DIY