It's time for another mini project in the series of practical 3D printing - I invite you to report on the design of the replacement for the lamp mounting element in Blender, all step by step, along with a demonstration of the final result. The original element was metal but after two years it broke, can PLA do the job here?

I presented the lamp three years ago in the topic: Large "third hand", magnifier, USB lamp - Newacalox - review

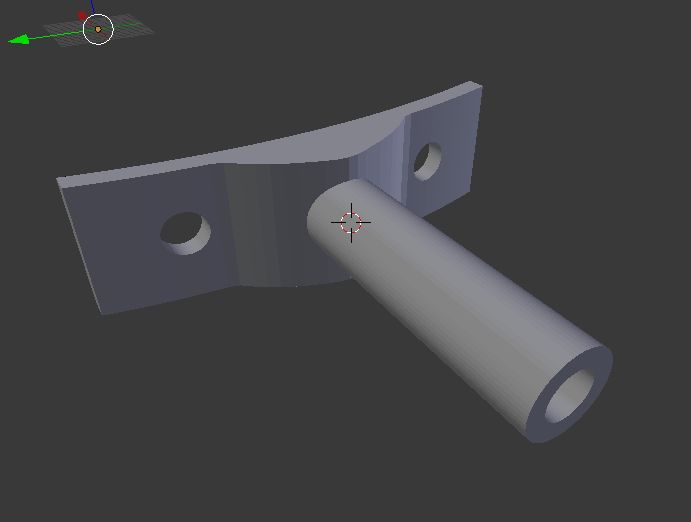

So the damage was done to this joint:

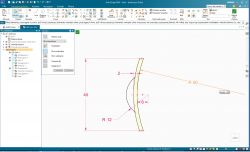

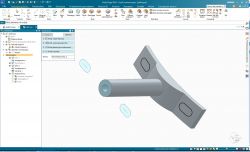

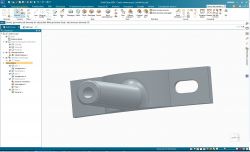

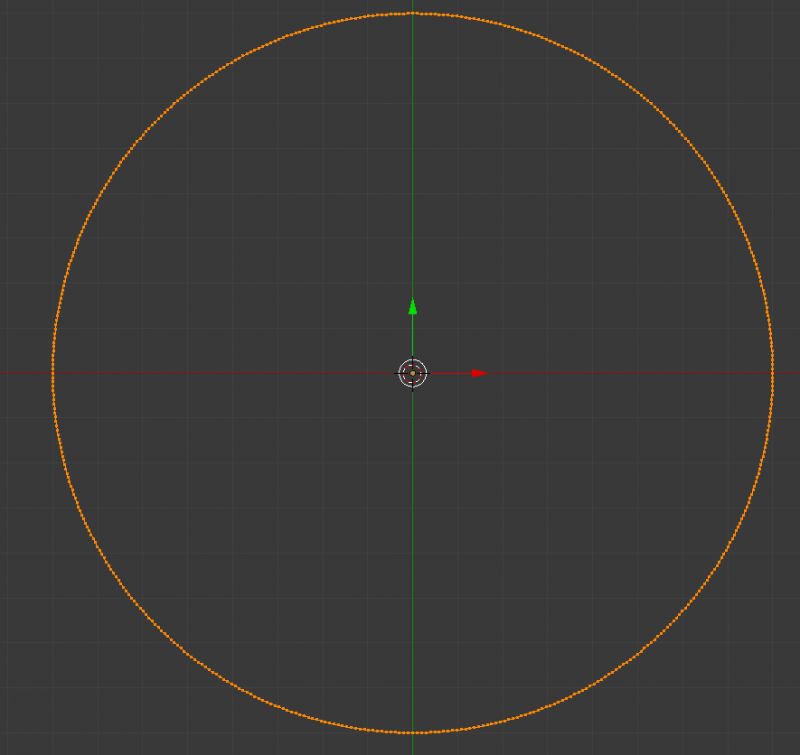

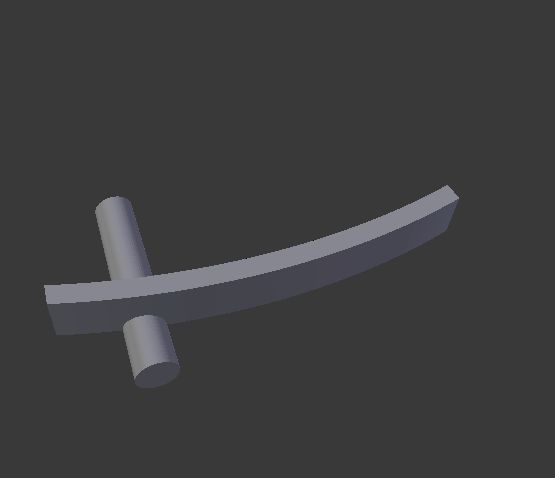

I created the replacement in Blender. I started the adventure with a circle of diameter in line with the diameter of the lamp:

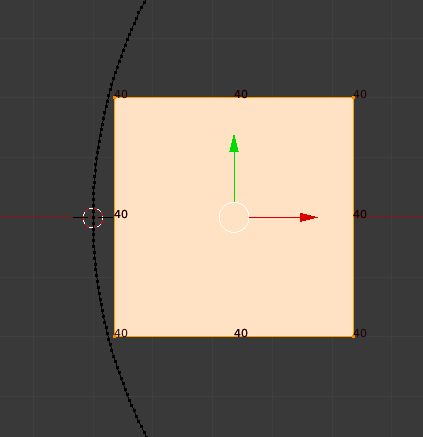

I then prepared myself a block with a length that matched the desired element (circle cutout):

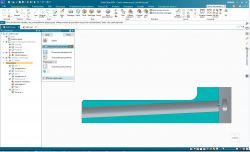

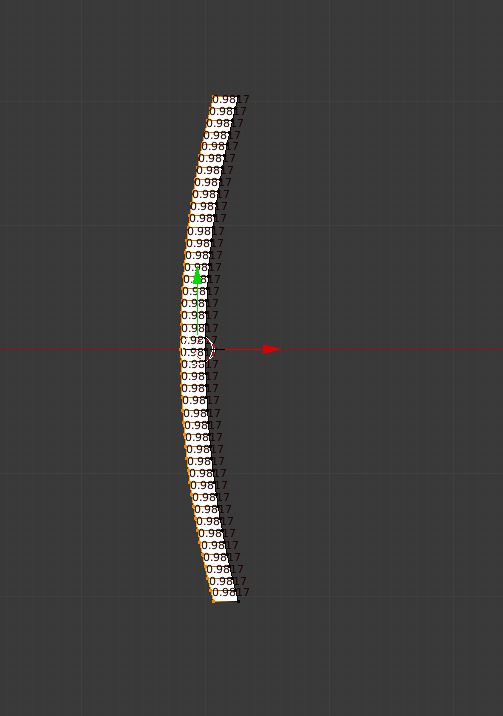

Based on this I cut out this cutout and gave it a thickness:

At this point it was still two-dimensional:

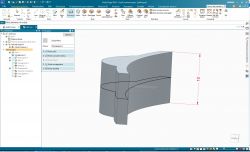

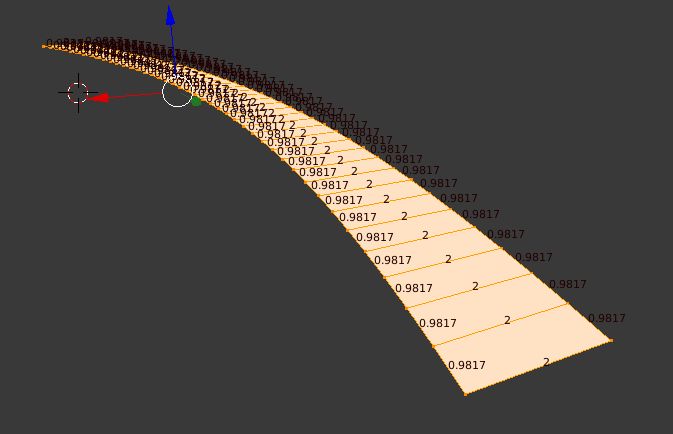

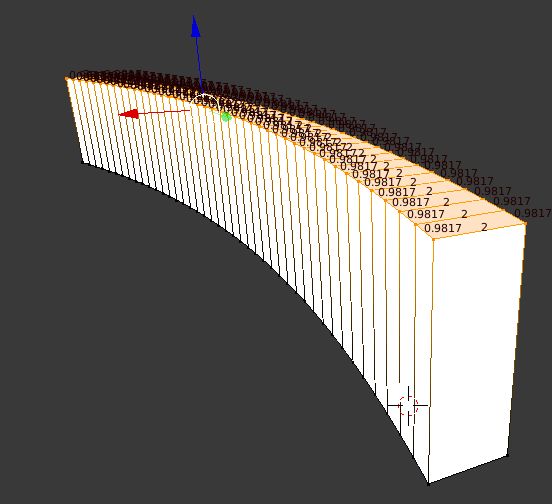

For this reason I then gave it a third dimension:

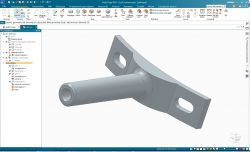

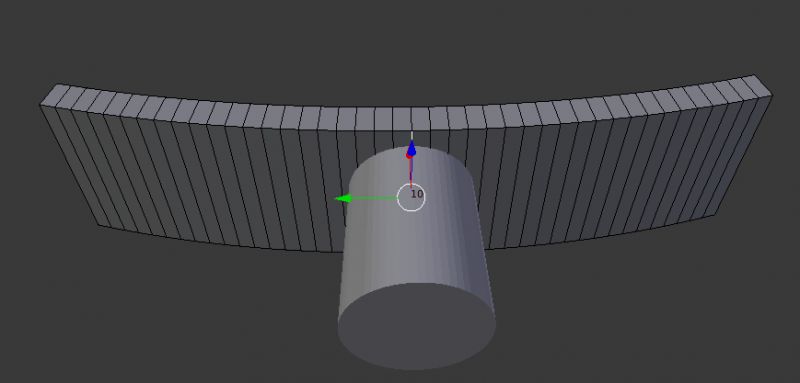

I made a print for the fitting:

Fits:

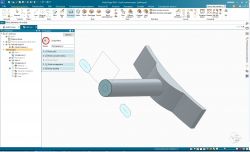

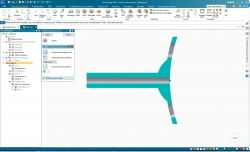

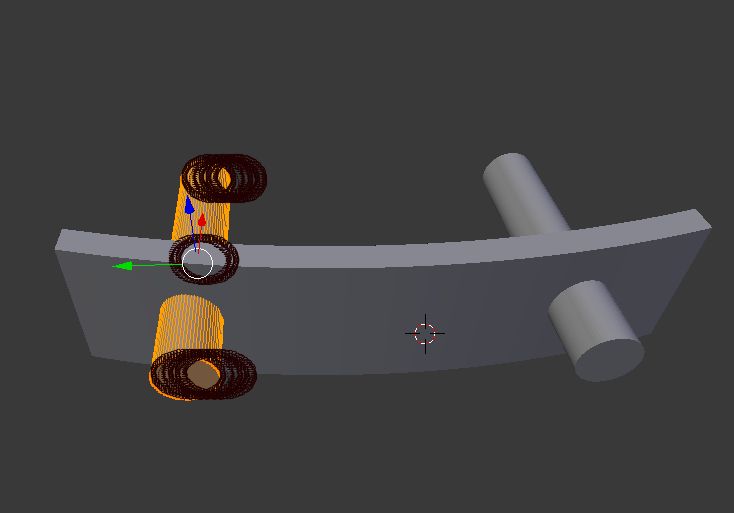

Now it's time for the holes. I have created the cylinder so that its origin point is on the symmetry axis of the piece, this in order to later add a mirror image to have the two holes symmetrically:

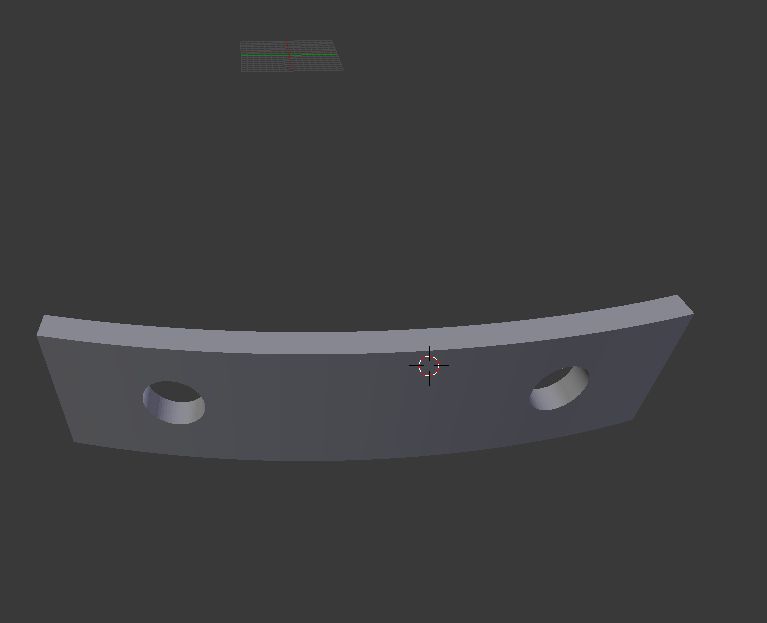

After adding the "mirror" modifier:

Then I added "boolean" - i.e. we cut a new shape from the previous element:

Then it was time for another cylinder, also with "boolean" - but this time a sum operation:

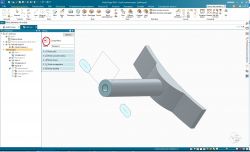

Fitting:

A few improvements later I still cut the third hole and the shape is tentatively ready:

The third hole is needed because the wires are routed through it.

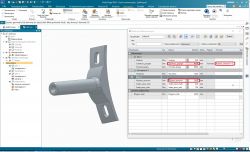

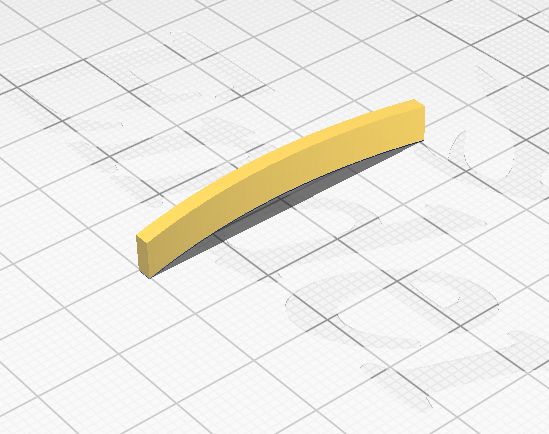

Printed component:

I printed the piece on a slant to reinforce the structure a little.

Done! Now the only question is how long it will last....

Summary

I waited about a month before writing the topic, during this time I have used the lamp normally and I can already state with a clear conscience that the print has performed well. Nothing has broken yet, and even if it does, I have a second piece in reserve. It costs practically nothing. The piece only weighs 2-3 grams, and considering that I pay about £50 for 1kg of filament it's really pennies, even including electricity and time spent in Blender.

Could it have been fixed any other way? I don't know, you guys can tell me, but in terms of my capabilities the 3D printing solution worked perfectly.

Cool? Ranking DIY Helpful post? Buy me a coffee.