Warm welcome.

I am looking for a willing person or very (very) simple instructions on how to modify the software in the avatto zwt 198 thermostat, specifically two parameters:

Hysteresis 0.5 to 0.1

The jump of the set temperature from 0.5 to 0.1.

.

.

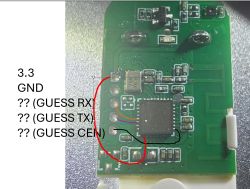

PCB designation 20230822 R9-433 V1.2

Ps. This is my first topic if I have made any mistakes I am very sorry and ready for criticism.

Greetings.

AI: Do you already have any tools or software that you are trying to use to modify the thermostat software? .

No

AI: What is your experience with software modification or electronics? Do you need detailed step-by-step instructions? .

Detailed step-by-step instructions.

I am looking for a willing person or very (very) simple instructions on how to modify the software in the avatto zwt 198 thermostat, specifically two parameters:

Hysteresis 0.5 to 0.1

The jump of the set temperature from 0.5 to 0.1.

.

.

PCB designation 20230822 R9-433 V1.2

Ps. This is my first topic if I have made any mistakes I am very sorry and ready for criticism.

Greetings.

AI: Do you already have any tools or software that you are trying to use to modify the thermostat software? .

No

AI: What is your experience with software modification or electronics? Do you need detailed step-by-step instructions? .

Detailed step-by-step instructions.