I have a project in mind.

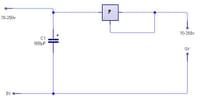

at the moment, i use a charged capacitor that i short out for the purpose of tack welding in my jewelry making. i would like to make it more user friendly as i have upto 250vdc hanging around at the end of a couple of crocodile clips . i would like to incorperate a way of switching the discharge instantly at the moment of short circuit (see image below ) so that my leads only become live at the point of short circuit. ...make sense ???

what sort of components should i be looking at for the switching ? please excuse my very limited knowlege of electronics

Sarah

at the moment, i use a charged capacitor that i short out for the purpose of tack welding in my jewelry making. i would like to make it more user friendly as i have upto 250vdc hanging around at the end of a couple of crocodile clips . i would like to incorperate a way of switching the discharge instantly at the moment of short circuit (see image below ) so that my leads only become live at the point of short circuit. ...make sense ???

what sort of components should i be looking at for the switching ? please excuse my very limited knowlege of electronics

Sarah