I would like to invite you to a destructive demonstration of a powerful outdoor LED lamp with a PIR motion sensor. The equipment came to me completely inoperable, so I decided to check its construction for teaching purposes. I was mainly puzzled by what was broken, and how the LED control and the motion sensor were implemented.

I don't know the model of this lamp, so the whole thing will be based on guesswork.

The housing is metal and solid, and you can also see that it has 'fins' on the back for heat dissipation. 50 W in LEDs is a lot of power though, and after all, not all of it turns into light. I wonder what efficiency the LEDs are in there.

I guess the previous owner decided that earthing was unnecessary and wired the whole thing with a two-wire wire.

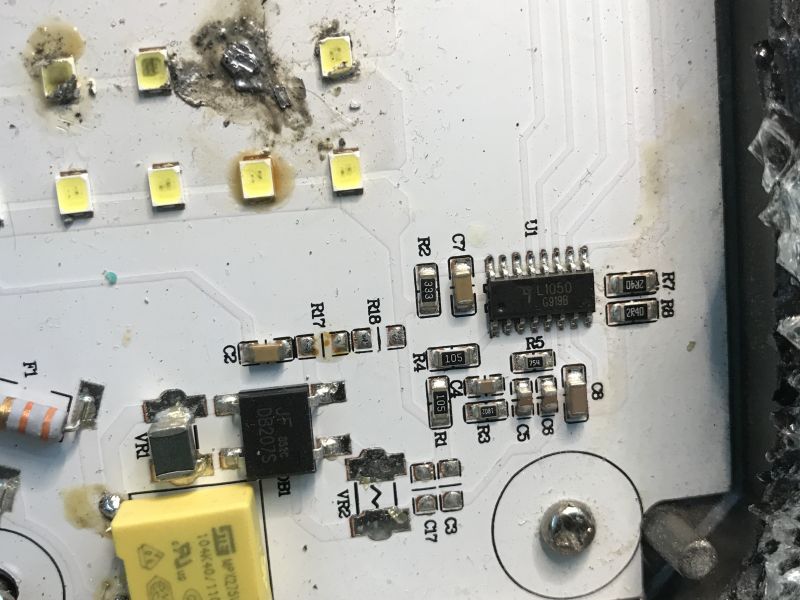

Here you can see a PIR sensor, I associate such from various other hardware, there are also such ready-made modules for Arduino. You can also see the LEDs punctured, this is probably how this hardware ended its life.

Unfortunately I have not found a way to get inside in a non-destructive way .

Hammer and drive. Good thing the whole thing is made of special glass that doesn't shoot shards left and right.

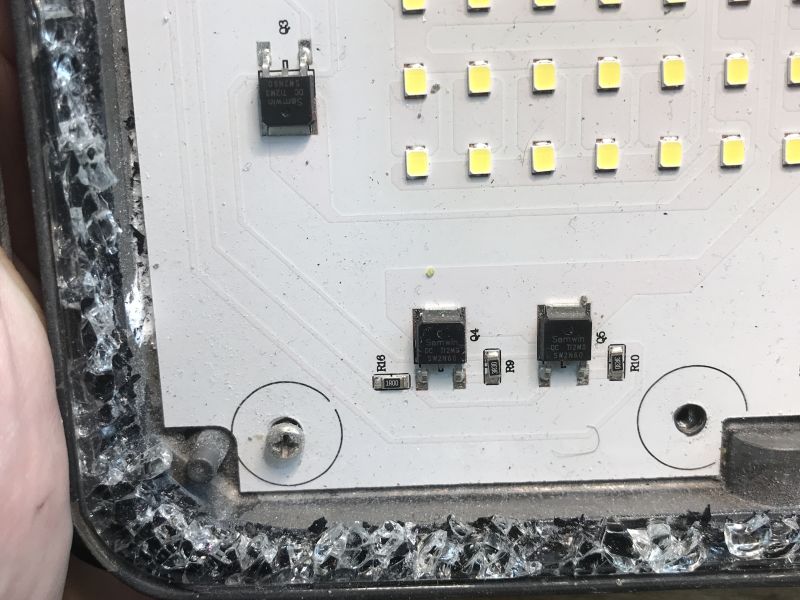

This way we almost have the interior. You can see that there are two separate modules inside. Probably copies without the PIR sensor are also produced. This module with PIR probably works.

Out of curiosity I tested the LEDs - some are faulty and a break in the circuit. Interestingly, some with black dots still work:

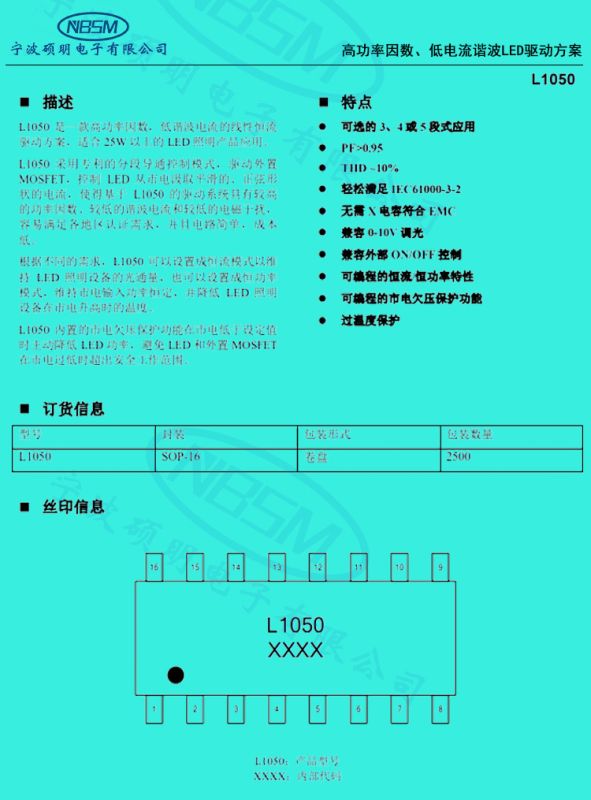

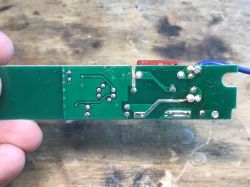

However, let's start at the beginning. There is a phase wire and a neutral wire to the board, with the phase wire connected through the motion sensor. Then we have two fuses, an anti-interference capacitor and a rectifier bridge. Circuit U1 (L1050) appears to be a constant-current LED controller and is powered directly from the mains.

Next we have the transistors, primarily I see the SW2N60 there:

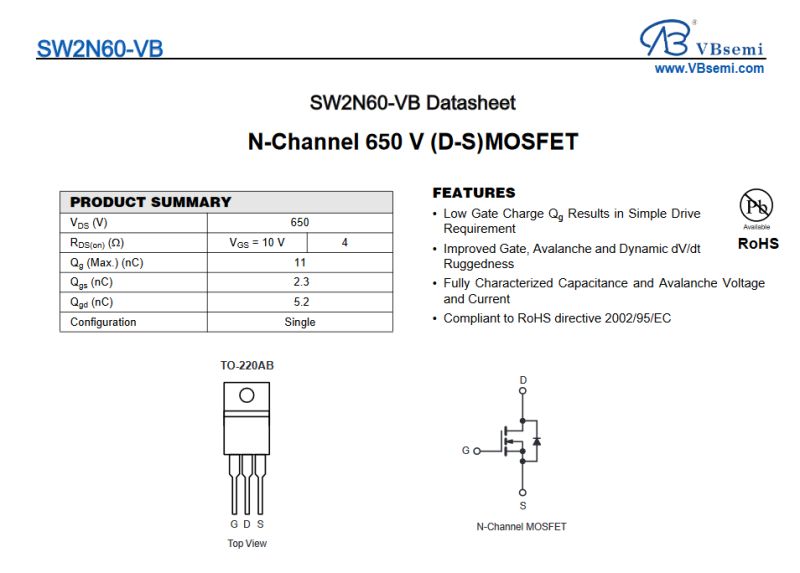

These are MOSFETs with an N-type channel for high voltage, I was surprised by their resistance in the open state:

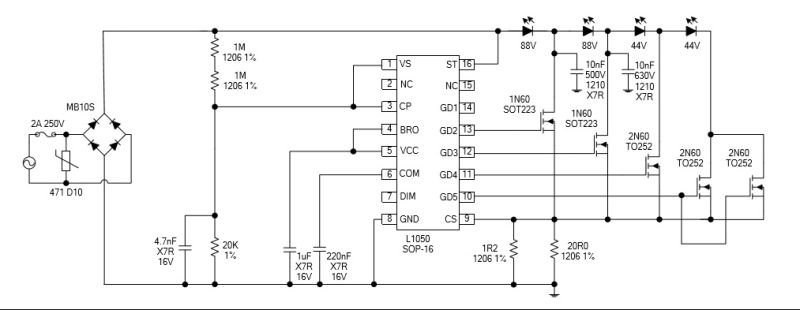

I managed to find a whole schematic showing a similar circuit:

I was quite surprised by the way the LEDs are connected, anyone know what purpose this is used for? The rest is pretty clear, the CS pin is used to measure current (via the voltage drop across the shunt resistor), the 1MΩ resistors to power the controller circuit.

What's left is the PIR module. A cool little gadget. There's even a fuse and a varistor.

The lamp is potentially repairable but it is now without glass and in addition soldering in new LEDs is difficult, the whole thing effectively dissipates heat. A heater would be useful.

In summary , this was more of a one-off. There was a separate PIR module and a separate LED board with a constant current controller supporting several strings. Looking at the damage to the LEDs I get the impression that the strings were failing sequentially, although given the attached diagram I have my doubts as to why this is (if it is) wired this way, perhaps someone else can explain.

Do you use these types of LED lights, how do you find their failure rate and longevity?

Cool? Ranking DIY Helpful post? Buy me a coffee.